Calcium Silicate Insulation Market Size:

The calcium silicate insulation market size is growing with a CAGR of 4.7% during the forecast period (2025-2032), and the market is projected to be valued at USD 403.80 Million by 2032 from USD 280.91 Million in 2024. Additionally, the market value for 2025 attributes to USD 293.07 Million.

Calcium Silicate Insulation Market Scope & Overview:

The calcium silicate insulation is a high-performance, durable and rigid thermal insulation material. It is mainly made up of calcium silicate, reinforced with fibers. This material possesses properties such as moisture resistance, chemical resistance and good thermal insulation. It comes in various forms such as blocks, pipe sections, curved segments, and board. It is used in various industries including metal, construction, energy & power, petrochemical, and others. This material is sold through direct sales, retail sales, and online sales to power generation plants, steel manufacturers, and construction companies. Additionally, demand for non-toxic and eco-friendly insulation material including calcium silicate is rising further driving the market.

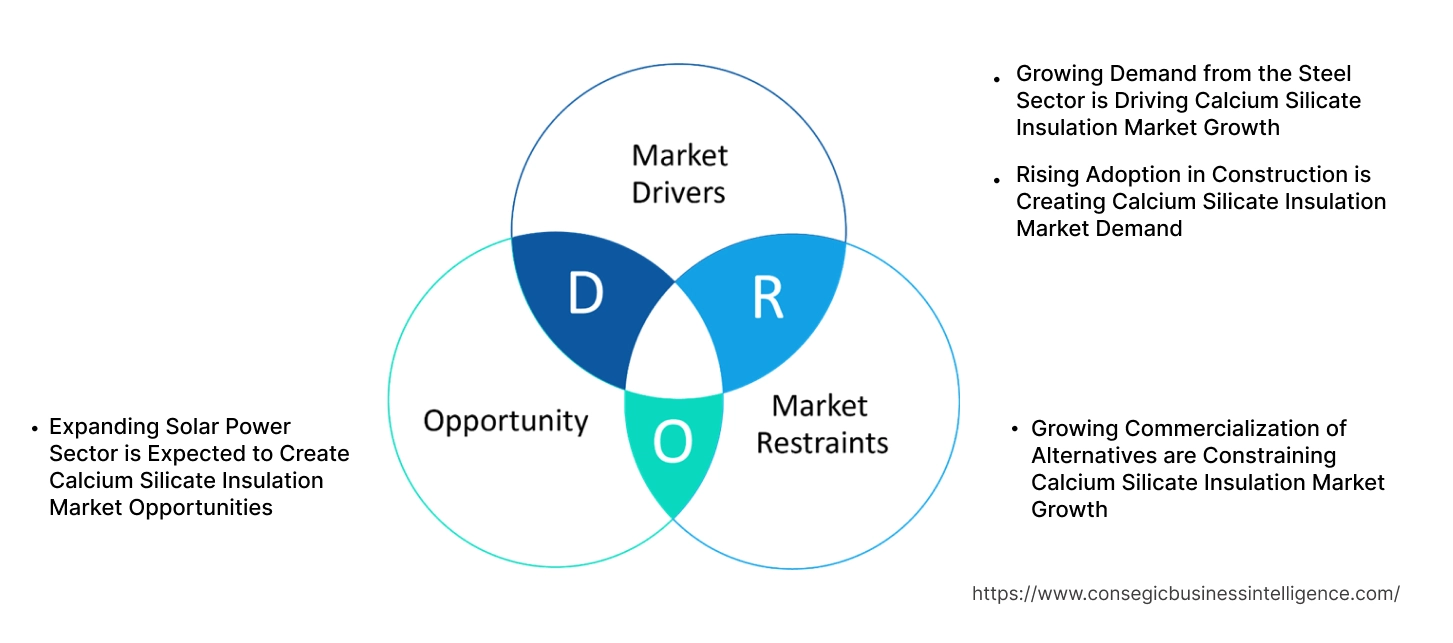

Calcium Silicate Insulation Market Dynamics - (DRO) :

Key Drivers:

Growing Demand from the Steel Sector is Driving Calcium Silicate Insulation Market Growth

The calcium silicate insulation is extensively utilized in the steel sector to provide slag resistance. It also provides fire-resistant barriers in steel production. Further, steel production is growing due to expanding construction projects, urbanization and rising manufacturing plants, further driving the market.

- According to International Trade Administration, the steel production in United States is increased by 1.2% in 2024 as compared to the year 2023. This growing steel production is driving the use of calcium silicate insulation for fireproofing and slag resistance in steel sector.

Hence, growing demand from the steel sector is leading to calcium silicate insulation market demand.

Rising Adoption in Construction is Creating Calcium Silicate Insulation Market Demand

In construction, calcium silicate insulation is used in walls, ceilings, and floors. It provides fire resistance and thermal insulation in commercial and residential buildings. It is also used for wall cladding to provide an excellent protective layer for exterior walls. Further, construction is growing due to rising population, government support and urbanization further driving the market.

- According to CEIC, the construction in China is increased by 17.60% in 2022 as compared to the year 2021. This growing construction is driving the use of calcium silicate insulation for wall cladding and thermal insulation in buildings.

Thus, rising adoption in construction is leading to calcium silicate insulation market expansion.

Key Restraints:

Growing Commercialization of Alternatives are Constraining Calcium Silicate Insulation Market Growth

Commercialization of alternative insulation materials such as fiber glass, mineral wool, and cellular glass is growing. They provide similar thermal insulation and fire resistance as that of calcium silicate insulation material. Compared to this insulation material, mineral wool has low installation costs and is easy to replace making it more suitable for ceiling and walls. Further, fiber glass is lighter in weight making handling and installation easier. Additionally, the use of cellular glass is growing in a high impact environment due to its ability to perform well under mechanical stress. Hence, commercialization of alternative insulation materials such as fiber glass, mineral wool, and cellular glass is constraining the market growth due to low-installation cost and easy replacement.

Future Opportunities :

Expanding Solar Power Sector is Expected to Create Calcium Silicate Insulation Market Opportunities

Solar power sector converts energy from the sun into electricity through the use of solar panels. In this sector, calcium silicate insulation is used as a backing material for solar panels, providing thermal insulation and protection for the photovoltaic cells. It also provides moisture resistance to maintain structural integrity in solar panels. The solar power sector is growing supported by government initiatives, sustainability, and digital innovation.

- According to SolarPower Europe, the solar power sector is anticipated to grow by 3-7% by 2028 from 2024. This growth will create opportunities for the market due to growing preference for insulation materials with better thermal conductivity and moisture resistance.

Hence, expanding solar power sector is expected to create calcium silicate insulation market opportunities.

Calcium Silicate Insulation Market Segmental Analysis :

By Form:

Based on form, the market is categorized into blocks, pipe sections, curved segments, and board.

Trends in Form:

- According to calcium silicate insulation market trends, calcium silicate blocks are used widely due to high-temperature insulation and better structural integrity.

- Use of calcium silicate pipe sections are growing due to significant investment in clean energy manufacturing as per market trends.

The blocks segment accounted for the largest market share in the year 2024.

- The calcium silicate blocks are high-temperature, lightweight, and durable insulation materials.

- They are designed to provide thermal insulation, fire resistance, and mechanical strength.

- These blocks are able to withstand temperatures above 1000 °C, making them suitable for applications such as industrial furnaces, kilns, and boilers.

- Additionally, these blocks offer better structural integrity than other forms contributing to their widespread use.

- Further, the manufacturers of steel, cement, and glass are using these blocks due to their non-combustible and fire safety properties.

- Hence, these blocks are widely used due by steel and glass manufacturers supported by rising awareness of fire safety further driving the segment.

The pipe section’s segment is expected to grow at the fastest CAGR over the forecast period.

- The calcium silicate pipe sections are pre-formed, high-temperature insulation materials.

- These pipe sections are widely used in clean energy manufacturing as well as in oil & gas refineries for protecting pipelines from high temperatures and fire.

- Further, industries such as chemicals are focusing towards carbon reduction goals and sustainability, leading to more use of clean energy. To cater this, governments are investing in clean energy manufacturing.

- For instance, in 2025, United States Department of Energy, government invested USD 230 billion in clean energy manufacturing. This will create potential for calcium silicate pipe sections manufacturers to provide thermal insulation and fire resistance in pipelines in clean energy manufacturing.

- Hence, investment in clean energy manufacturing is growing which is driving the use of calcium silicate pipe sections for thermal insulation, thereby driving the growth of the segment.

By End-Use:

Based on end-use, the market is categorized into metal, construction, energy & power, petrochemical, and others.

Trends in End-Use:

- As per create calcium silicate insulation market trends, insulation material made from calcium silicate is extensively used in the manufacturing of metals to provide thermal efficiency.

- Adoption of calcium silicate insulation is growing in electricity generation for minimizing heat loss as per market trends.

The metal segment accounted for the largest market share in the year 2024.

- The metal sector involves the extraction, processing, and manufacturing of metals such as steel, aluminium, and copper.

- In this sector, calcium silicate insulation is used extensively to provide high temperature resistance and thermal efficiency. It also provides fireproofing for furnaces, ladles, kilns, and pipelines.

- This insulation material is asbestos-free and non-toxic which also provides moisture resistance to metal equipment which enhances its lifespan.

- Further, governments are implementing stringent regulations to reduce the non-toxicity in metal operations which leading to more use of insulation materials such as calcium silicate.

- Thus, calcium silicate insulation is extensively used in manufacturing of metals due to its non-toxicity and stringent government regulations further driving the segment.

The energy & power segment is expected to grow at the fastest CAGR over the forecast period.

- The energy and power sector encompasses the generation, transmission, and distribution of electricity.

- In this sector, calcium silicate insulation is used to enhance electricity generation by minimizing heat loss through boilers, steam turbines and heat exchangers.

- Further, digital infrastructure, urbanization and number of industrial plants are growing which requires large amount of electricity. To cater this, countries are increasing their electricity generation.

- For instance, according to Ministry of Power, electricity generation in India represented a growth of 7.04% in 2024 as compared to the year 2023. This growing electricity generation is leading to more use of calcium silicate for thermal insulation and process efficiency.

- Hence, electricity generation is growing which is requiring high-temperature insulation material further driving the growth of the segment.

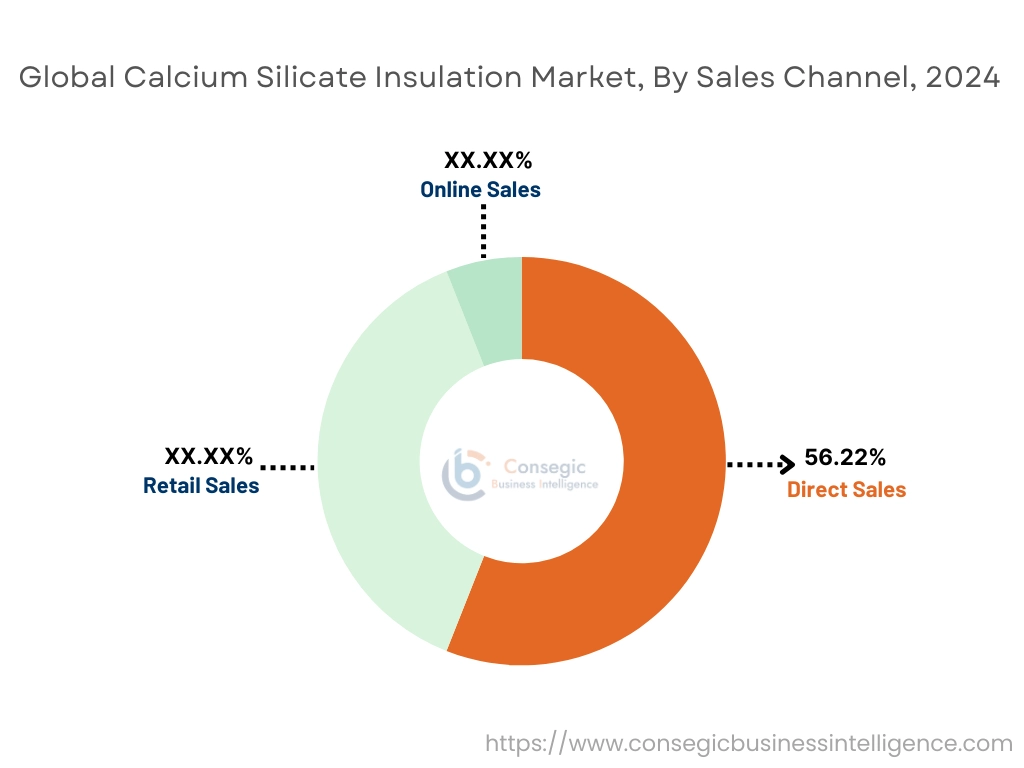

By Sales Channel:

Based on Sales channel, the market is categorized into direct sales, retail sales, and online sales.

Trends in Sales Channel:

- Calcium silicate insulation is widely sold through direct sales to construction companies and metal manufacturers ensuring bulk and consistent product supply.

- Adoption of online sales is growing for the sale of this insulation material due to wider reach and customer convenience as per market trends.

The direct sales segment accounted for the largest market share of 56.22% in the year 2024.

- Direct sales are a type of sales channel where products are sold directly to customers without any intermediaries.

- Calcium silicate insulation is widely sold through direct sales to oil & gas companies, power generation plants, and construction companies directly.

- It helps to build strong relationships with customers and ensures control over the entire sales process, from pricing to delivery, ensuring higher margins and personalized offerings.

- Direct sales provide a bulk amount of this insulation to the petrochemical manufacturers, ensuring better product quality and consistent supply.

- Thus, the direct sales segment is dominating in the sales channel supported by ensuring bulk supply and better product quality to the customers.

The online sales segment is expected to grow at the fastest CAGR over the forecast period.

- Online sales are a type of sales channel that refers to the selling of goods and services online through digital platforms and marketplaces.

- The sale of calcium silicate insulation through online sales is growing due to wider reach and customer convenience.

- Further, digitalization and greater access to the global market has led to the widespread adoption of online sales by comparing products of various brands with detailed description and user reviews.

- For instance, according to Global Times, the online sales in China is increased by 11% in 2023 as compared to the year 2022. This includes calcium silicate insulation which is distributed through online sales to construction companies, steel manufacturers, and power generation plants.

- Thus, the adoption of online sales is growing in the market due to wider customer reach and detailed product descriptions.

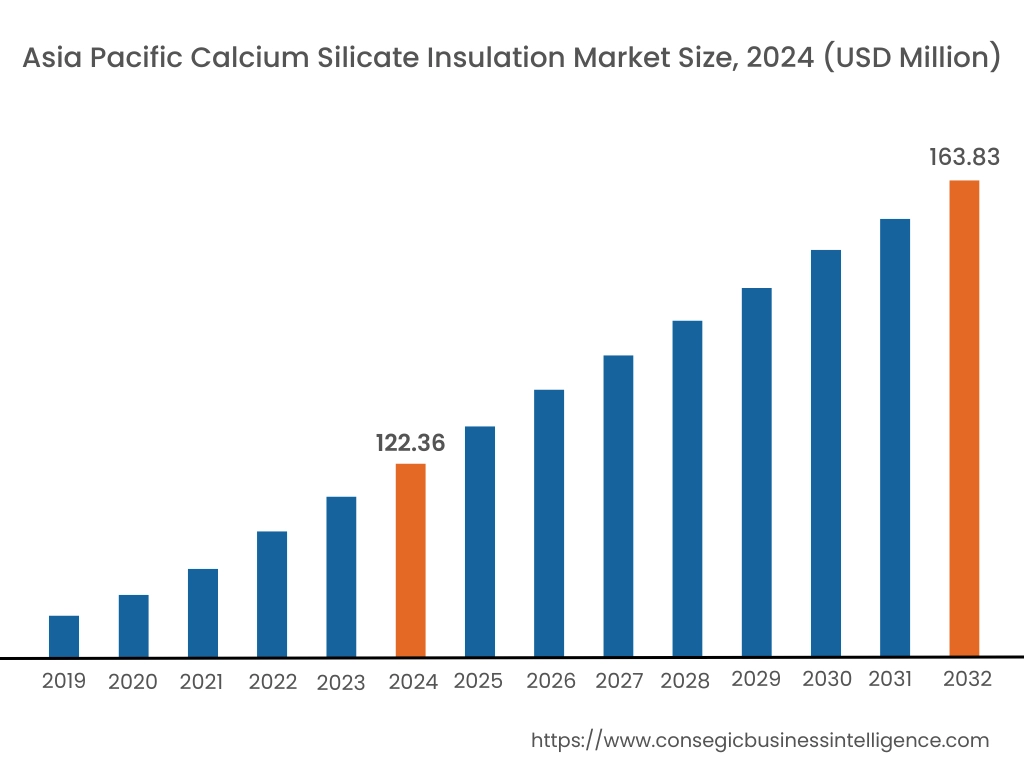

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

In 2024, Asia-Pacific accounted for the highest market share at 43.56% and was valued at USD 122.36 Million and is expected to reach USD 163.83 Million in 2032. In Asia-Pacific, the China accounted for the highest calcium silicate insulation market share of 36.11% during the base year of 2024. As per analysis, the Asia Pacific region holds a dominant position in the market due to expanding metal production. The calcium silicate insulation is utilized in metal production for reducing heat loss and improving process efficiency. Countries such as China, India, and South Korea leads the market in the region.

- According to Ministry of Mines, the copper production in India is increased by 6% in 2024 as compared to the year 2023. This growing copper production is driving the use of calcium silicate insulation to improve process efficiency through minimizing heat loss.

Therefore, the Asia Pacific region is dominating in the market, supported by expanding metal production as per analysis.

Europe is expected to witness the fastest CAGR of 6.5% over the forecast period of 2025-2032. According to calcium silicate insulation market analysis, Europe region is growing considerably driven by stringent environmental regulations and strong focus on sustainability. The region is adopting eco-friendly and non-toxic insulation material. This is driving the adoption of calcium silicate insulation due to its recyclability and land fill disposability. The region is also implementing regulations such as Waste Framework Directive to promote use of non-hazardous insulation material further driving the market. Hence, calcium silicate insulation market share of Europe is expected to emerge rapidly through stringent regulations and adoption of non-toxic insulation material as per analysis.

As per calcium silicate insulation market analysis, the North America region is growing rapidly driven by advancements in technology. Innovation in lightweight, high-strength formulations have improved durability while maintaining fire resistance and thermal insulation properties. Further, the integration of nano-coating enhances the moisture resistance properties of this insulation material, making it suitable in harsh environments.

The Middle East & Africa region is experiencing moderate expansion in the market driven by growing petrochemical industry. It is driving the use of calcium silicate blocks in this industry for partitions and enclosures due to its durability and load-bearing capacity. The governments in the region are also investing in the petrochemical sector further leading to calcium silicate insulation market expansion as per analysis.

As per market analysis, Latin America is growing steadily in the market driven by rising disposable incomes and steady economic development across the region. Increasing urbanization and industrialization has led to more construction thereby driving the adoption of calcium silicate sheets in building materials. Countries such as Brazil, Mexico, and Argentina are leading the market supported by growing population, expanding industrialization and infrastructure development.

Top Key Players & Market Share Insights:

The calcium silicate insulation industry is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global calcium silicate insulation market. Key players in the calcium silicate insulation industry include-

- Etex Group (Belgium)

- Johns Manville (United States)

- USG Corporation (United States)

- Ramco Hilux (India)

- Zhejiang Xinguang Building Materials (China)

- A&A Material Corporation (Japan)

- Isolatek International (United States)

- L'ISOLANTE K-FLEX (Italy)

- SaintGobain (France)

- NICHIAS Corporation (Japan)

Calcium Silicate Insulation Market Report Insights:

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 403.80 Million |

| CAGR (2025-2032) | 4.7% |

| By Form |

|

| By End-Use |

|

| By Sales Channel |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the calcium silicate insulation market? +

In 2024, the calcium silicate insulation market is USD 280.91 million.

Which is the fastest-growing region in the calcium silicate insulation market? +

Europe is the fastest-growing region in the calcium silicate insulation market.

What specific segmentation details are covered in the calcium silicate insulation market? +

Form, End-Use and Sales Channel are covered in the calcium silicate insulation market.

Who are the major players in the calcium silicate insulation market? +

Etex Group (Belgium), Johns Manville (United States), A&A Material Corporation (Japan) are some of the major players in the market.