Industrial Controllers Market Size :

Industrial Controllers Market Size is estimated to reach over USD 242.74 Billion by 2032 from a value of USD 149.35 Billion in 2024 and is projected to grow by USD 156.04 Billion in 2025, growing at a CAGR of 6.3% from 2025 to 2032.

Industrial Controllers Market Scope & Overview:

An industrial controller is a specialized electronic device that serves as the central component in industrial automation and manufacturing processes. The controllers efficiently manage and monitor various machinery, equipment, and processes within an industrial setting, executing predefined tasks, and control functions to ensure the smooth operation of production processes. There are several factors driving the demand for the controller including the growing trend of industrial automation, increased standards for improved quality, enhanced productivity, and energy efficiency among others.

Industrial Controllers Market Insights :

Industrial Controllers Market Dynamics - (DRO) :

Key Drivers :

Increasing industrial automation drives the market.

Industrial automation aims to streamline and optimize manufacturing and production processes. They play a pivotal role in industrial automation by automating processes, ensuring consistent and efficient operations, increasing productivity, and reducing downtime. The aforementioned advantages play an important role in driving the market expansion of industrial automation, which in turn drives the adoption of the controllers. Assessment of market trends suggests that growth in technological advancements such as IoT (Internet of Things), artificial intelligence, machine learning, and robotics are also leading to the increased automation of industries.

Additionally, advanced controllers are equipped with data collection and analysis capabilities. The controllers gather real-time data from sensors including magnetic field and sensors, providing valuable insights into production performance, leading to better process optimization. For instance, in May 2023, OMRON Automation launched a NX502 industrial controller to provide real-time analysis and process optimization. The product is designed to provide high-speed safety, reduce lead times, and maximize energy productivity, hence contributing notably to bolstering the market proliferation.

Thus, factors including increased productivity, reduced downtime, and technological advancement are leading to increased automation, which in turn results in the increase of industrial controllers market demand.

Stringent safety regulations to enhance worker safety.

Government regulations mandate specific safety standards and protocols that industries must adhere to function efficiently. Industrial controllers play a crucial role in ensuring that equipment and processes comply with safety standards. Additionally, safety regulations aim to minimize workplace accidents and hazards. The controllers enable proactive safety measures including monitoring equipment for anomalies, shutting down processes in emergencies, and implementing safety procedures. Moreover, they automate physically demanding tasks, reducing the exposure of workers to hazardous conditions and minimizing the potential for accidents. Examination of market trends concludes that the implementation of strict control rules to improve operational productivity and worker safety is contributing remarkably to driving the adoption of controllers. For instance, in August 2023, the Department of the Interior (Bureau of Safety and Environmental Enforcement (BSEE)), implemented new control measures to enhance worker safety and ensure offshore oil and gas operations on the outer continental shelf.

Thus, growing government regulation for workers' safety is driving industrial controllers market demand.

Key Restraints :

High manufacturing cost

The cost of production of industrial controllers is relatively high which prevents small-medium enterprises with limited budgets from adopting the controllers. Additionally, the components used in manufacturing controllers including input/output (I/O) modules, sensors, and central processing unit (CPU) are also expensive. Consequently, the high manufacturing cost deters small organizations from investing in the controllers, thus hampering the global industrial controllers' market expansion.

Future Opportunities :

Integration with Industry 4.0 presents significant opportunities.

Industry 4.0 emphasizes highly automated and interconnected manufacturing processes. Industrial controllers are central to organizing automation, leading to an increasing need for advanced controllers capable of managing complex interconnected systems. Additionally, it relies on real-time data analysis to optimize operations. The controllers integrated with Industry 4.0 collect and analyze vast amounts of data from sensors and equipment, providing insights for process optimization.

Factors including the growing trend of digitalization, technological advancements such as cloud computing, machine learning, artificial intelligence, and improved efficiency are driving the demand. Additionally, the growing need for quality improvement, cost reduction, and competitive advantage also helps in spurring its demand. In this revolution, the controllers use data analytics and machine learning algorithms to predict the maintenance requirements of the machine, thus reducing downtime and extending equipment lifespan. Assessment of market trends suggests that the integration of controllers with Industry 4.0 is expected to emerge as one of many industrial controllers market opportunities that drive market expansion.

Industrial Controllers Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 242.74 Billion |

| CAGR (2025-2032) | 6.3% |

| By Type | Programmable Logic Controller (PLC), Computerized Numerical Controller (CNC), Distributed Control System (DCS), Programmable Automation Controller (PAC), Supervisory Control and Data Acquisition (SCADA), Industrial Automation and Control System (IACS), and Human-Machine Interface (HMI) |

| By Control | Open Loop Control, Closed Loop Control, ON-OFF Control, Feedforward Control, and Feedback Control |

| By Application | Pumping and Ventilation, Electrical Charging, Waste Water Management, Assembling and Filling, Smart Grid, and Others |

| By End-User | Food Processing & Beverages, Automotive, Manufacturing, Transportation, Energy & Utilities, Oil & Gas, and Others |

| By Region | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

| Key Players | NATIONAL INSTRUMENTS CORP, Ascon Tecnologic S.r.l., Siemens AG, Mitsubishi Electric Corporation, Emerson Electric Co., GE Electric, Red Lion (Spectris), Schneider Electric, ABB, Honeywell International Inc. |

Industrial Controllers Market Segmental Analysis :

By Type :

The type segment is classified into Programmable Logic Controller (PLC), Computerized Numerical Controller (CNC), Distributed Control System (DCS), Programmable Automation Controller (PAC), Supervisory Control and Data Acquisition System (SCADA), Industrial Automation and Control System (IACS), and Human-Machine Interface (HMI). In 2024, the Programmable Logic Controller (PLC) segment accounted for the highest industrial controllers market share as PLCs offer diagnostic capabilities that assist in troubleshooting and preventive maintenance. PLCs log data, track performance, and provide alerts, and enable timely maintenance and reduced downtime. Additionally, PLCs are designed to operate in harsh industrial environments with temperature variations, dust, humidity, and electrical noise. PLCs are built to withstand harsh conditions and provide reliable performance, crucial in industrial settings. For instance, Omron Corporation offers CP2E programmable logic controller for harsh environmental conditions. Thus, considering overall trends the increasing need for Programmable Logic Controller (PLC) is expected to drive the industrial controllers market growth.

Distributed Control System (DCS) is predicted to witness the fastest CAGR in the industrial controllers market during the forecast period. The proliferation is attributed to the expanding industrial automation for efficiency, cost savings, and improved control that raises the requirement of DCSs. DCSs provide a centralized platform for monitoring and controlling complex processes, becoming a crucial component in industrial automation. Additionally, DCSs enable remote monitoring and control, especially valuable for industries with distributed facilities to operate in remote or hazardous environments. Moreover, DCSs are incorporating advanced analytics and machine learning capabilities to improve predictive maintenance and process optimization. The industrial controllers market analysis concluded that the aforementioned factors are contributing collectively to bolstering the expansion of the market.

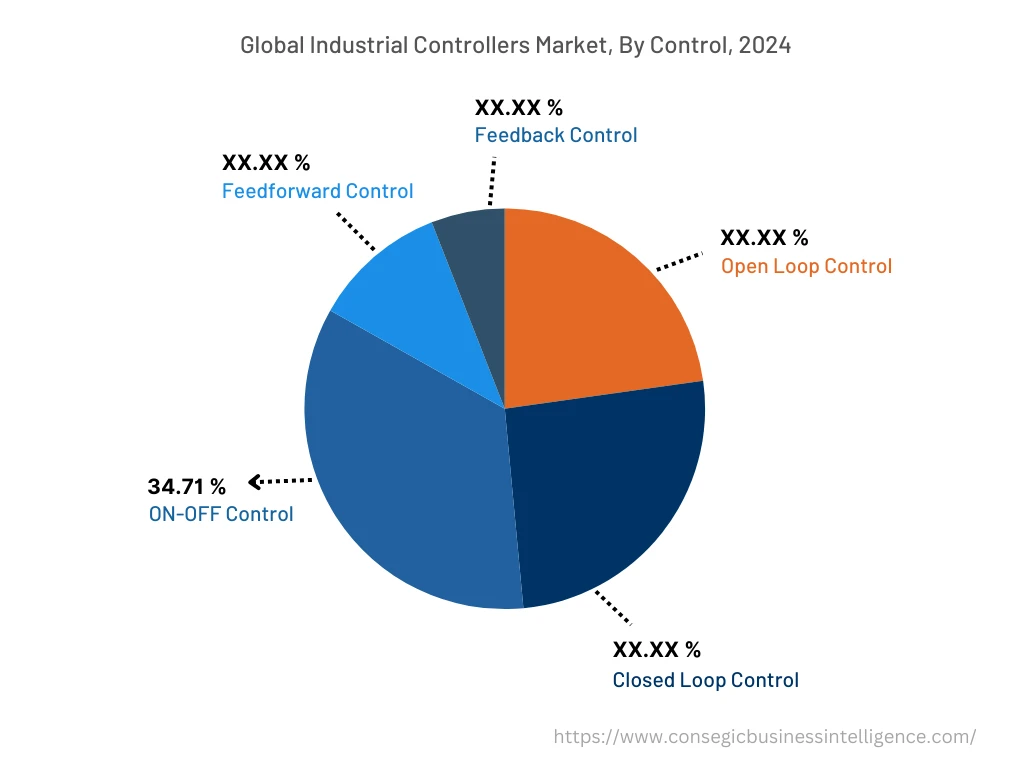

By Control :

The control segment is categorized into open-loop control, closed-loop control, on-off control, feedforward control, and feedback control. On/off control accounted for the largest market share of 34.71% in 2024 as on/off control is one of the simplest and most cost-effective control strategies. In addition, on/off controllers are used in industrial processes with harsh conditions and withstand harsh environments to provide reliable control without the need for frequent adjustments. Moreover, the on/off control system also contributes to energy-saving capabilities, further contributing to the demand for on/off control.

Closed-loop control systems are expected to witness the fastest CAGR in the industrial controllers market owing to the rising requirement from manufacturing, chemical processing, and pharmaceutical industries to maintain product quality and consistency. Additionally, closed-loop control allows for more efficient use of resources, including energy. Closed-loop systems continuously monitor and adjust the control output in response to changing conditions and optimize energy consumption, leading to cost savings and reduced environmental impact. The industrial controllers market analysis concluded that closed-loop control systems play a central role in process automation by providing real-time monitoring and adjustment of variables, further contributing to the proliferation of the market.

By Application :

The application segment is divided into pumping and ventilation, electrical charging, wastewater management, assembling and filling, smart grid, and others. Smart grids accounted for the largest market share in 2024 as controllers manage and coordinate the operation of distributed energy resources (DERs) including solar panels, wind turbines, and battery storage systems. The controllers ensure that power generation and consumption are balanced to maintain grid stability. Moreover, controllers collect data from sensors and meters placed throughout the grid, enabling operators to monitor voltage levels in real time. For instance, in January 2023, ABB invested in OKTO GRID to digitalize the energy grid to meet the growing requirement for reliable and stable power. Furthermore, the increasing investments by key players in developing smart grid systems are also contributing notably to fueling the industrial controllers market growth.

Electrical charging is expected to register the fastest CAGR during the forecasted period, as controllers are used to manage and control the operation of charging stations, including monitoring the availability of charging ports, handling user authentication and payment processing, and coordinating the charging process. Additionally, controllers ensure that electrical charging stations distribute power efficiently, avoiding overloading the grid or the charging infrastructure. Moreover, the controllers are also responsible for safety functions including monitoring temperature and voltage levels during charging to prevent overheating and overvoltage conditions. Analysis of industrial controllers' market trends concludes that the aforementioned factors are contributing significantly to bolstering the growth of the market.

By End-User :

The end-user segment is divided into food processing & beverages, automotive, manufacturing, transportation, energy & utilities, oil & gas, and others. In 2024, the Manufacturing segment accounted for the highest industrial controllers market share as manufacturing involves complex processes that require precise control of variables including temperature, pressure, flow rates, and material handling. The controllers play a crucial role in ensuring that the processes run efficiently and consistently, leading to higher product quality and reduced waste.

Additionally, manufacturers are increasingly focused on energy efficiency to reduce operational costs and minimize the environmental footprint. The controllers help to optimize energy consumption by regulating equipment and processes to operate at peak efficiency. Moreover, manufacturing equipment has long lifecycles, and controllers need to be reliable and durable to support extended operations. Manufacturers invest in proven and reliable control systems, contributing to the dominance of controllers in the manufacturing sector.

The automotive sector is predicted to register the fastest CAGR in the industrial controllers market in the upcoming years. The growth is attributed to the shift towards electric vehicles as controllers are used to charge and discharge EV batteries efficiently. The controllers monitor battery health, balance cells, and ensure safe charging. Additionally, the controllers also manage the power electronic systems including inverters and converters, crucial for converting DC power from the battery to AC power for the electric motor and vice versa. Analysis of industrial controllers market trends concludes that the increasing sales of electric vehicles are contributing remarkably to bolstering the growth of the market. For instance, according to the Canadian government, 303,073 hybrid electric vehicles, 152,685 battery electric vehicles, and 95,896 plug-in electric vehicles were registered in Canada in 2021.

By Region :

The regional segment includes North America, Europe, Asia Pacific, Middle East and Africa, and Latin America.

North America is estimated to reach over USD 78.67 Billion by 2032 from a value of USD 49.54 Billion in 2024 and is projected to grow by USD 51.66 Billion in 2025. North America encompasses a diverse range of advanced manufacturing industries, including automotive, aerospace, electronics, and pharmaceuticals. The industries rely heavily on controllers for automation, process control, and quality assurance. Additionally, the North American industrial sector has a strong automation base to improve productivity, quality, and efficiency, increasing the need for industrial controllers, essential for automating manufacturing processes.

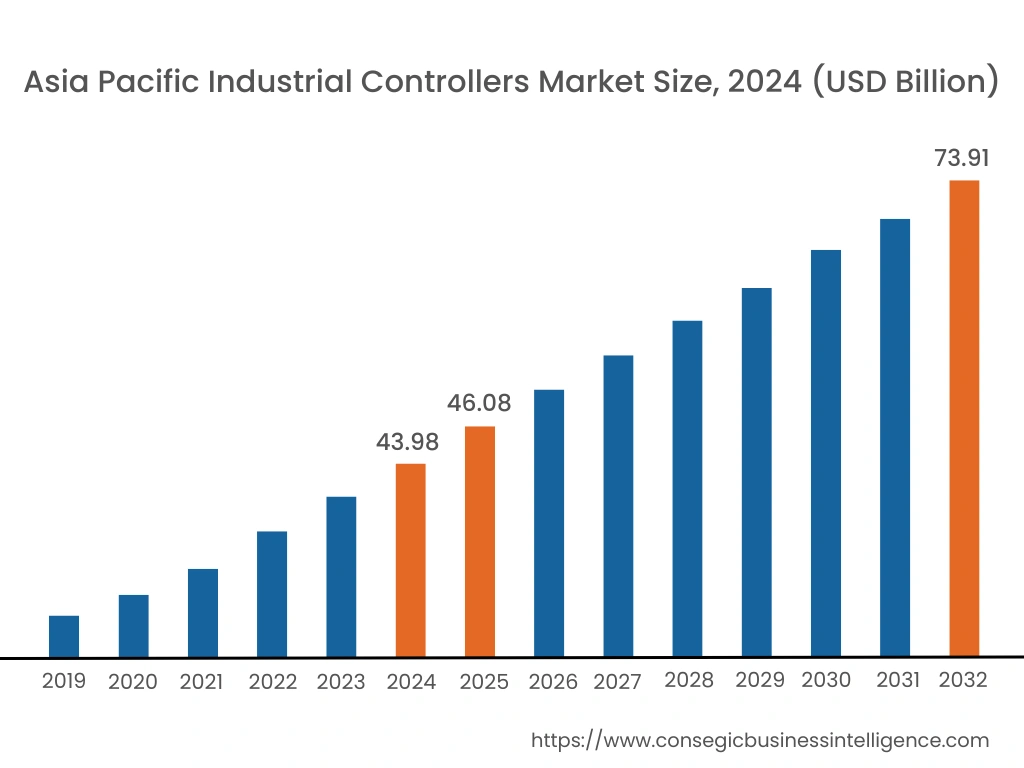

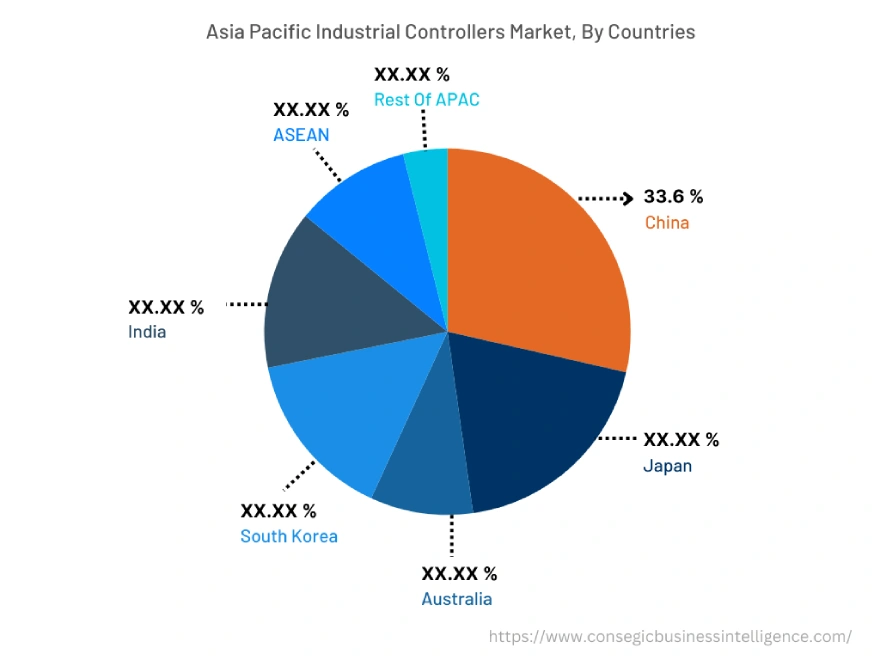

Asia-Pacific is expected to grow with the highest CAGR of 6.70% and is estimated to reach over USD 73.91 Billion by 2032 from a value of USD 43.98 Billion in 2024 and is projected to grow by USD 46.08 Billion in 2025. In addition, in the region, China accounted for the maximum revenue share of 33.6% in the same year. Asia Pacific countries, particularly China, are becoming major manufacturing hubs for the global economy. The region's expanding manufacturing base drives the need for advanced automation and control systems, including industrial controllers, to enhance productivity and competitiveness. Additionally, the Asia Pacific region has been investing heavily in infrastructure development, including smart cities, transportation networks, and energy infrastructure. The initiatives require advanced control systems to manage and optimize critical infrastructure components. For instance, in September 2023, according to the Ministry of External Affairs, India and the United States partnered together for Global Infrastructure and Investment (PGII) and the India-Middle East-Europe Economic Corridor (IMEC). The partnership aims at unlocking greater investment for infrastructure development and strengthening connectivity in various dimensions between India, the Middle East, and Europe. This, in turn, drives the industrial controllers market expansion.

Top Key Players & Market Share Insights:

The landscape of the industrial controllers market is highly competitive and has been examined in the report, along with complete profiles of the companies operating in the industrial controllers industry. In addition, the surge in innovations, acquisitions, mergers, and partnerships has further accelerated the growth of the industrial controllers market. Major players in the market include-

- NATIONAL INSTRUMENTS CORP

- Ascon Tecnologic S.r.l.

- Schneider Electric

- ABB

- Honeywell International Inc.

- Siemens AG

- Mitsubishi Electric Corporation

- Emerson Electric Co.

- GE Electric

- Red Lion (Spectris)

Recent Industry Developments :

- In May 2022, Emerson Electric Co. launched PACSystems RSTi-EP CPE 200, a Programmable Automation Controller (PAC) to support analytics and give end users a competitive advantage through increased efficiency, speed, and quality.

Key Questions Answered in the Report

What is an industrial controller? +

An industrial controller is a specialized electronic device that serves as the central component in industrial automation and manufacturing processes.

What specific segmentation details are covered in the industrial controllers market report, and how is the dominating segment impacting the market growth? +

On/off control accounted for the largest market share in 2024 as on/off control is one of the simplest and most cost-effective control strategies. In addition, on/off controllers are used in industrial processes with harsh conditions and withstand harsh environments to provide reliable control without the need for frequent adjustments.

What specific segmentation details are covered in the industrial controllers market report, and how is the fastest segment anticipated to impact the market growth? +

Distributed Control System (DCS) is predicted to witness the fastest CAGR in the industrial controllers market due to the expanding industrial automation for efficiency, cost savings, and improved control that raises the demand for DCSs.

Which region is anticipated to witness the highest CAGR during the forecast period, 2025-2032? +

Asia Pacific is anticipated to witness the fastest CAGR during the forecast period due to the expanding manufacturing sector.