Factory Automation Sensor Market Size:

Factory Automation Sensor Market size is estimated to reach over USD 25,083.64 Million by 2031 from a value of USD 14,877.69 Million in 2023 and is projected to grow by USD 15,616.51 Million in 2024, growing at a CAGR of 6.7% from 2024 to 2031.

Factory Automation Sensor Market Scope & Overview:

Factory automation sensor refers to the devices in industrial settings that are used to collect data on various physical parameters including temperature, pressure, motion, and proximity. It converts physical phenomena into measurable digital signals which are then displayed, enabling operators to read and proceed further. Additionally, these sensors provide accurate, real-time feedback to control systems, allowing machines to perform tasks efficiently to help the automation processes. Moreover, these sensors ensure the smooth functioning of machinery, enhancing productivity, and quality in manufacturing environments. The aforementioned factors of factory automation sensors are major determinants for their usage in manufacturing, automotive, electronics, and other industries.

Factory Automation Sensor Market Insights:

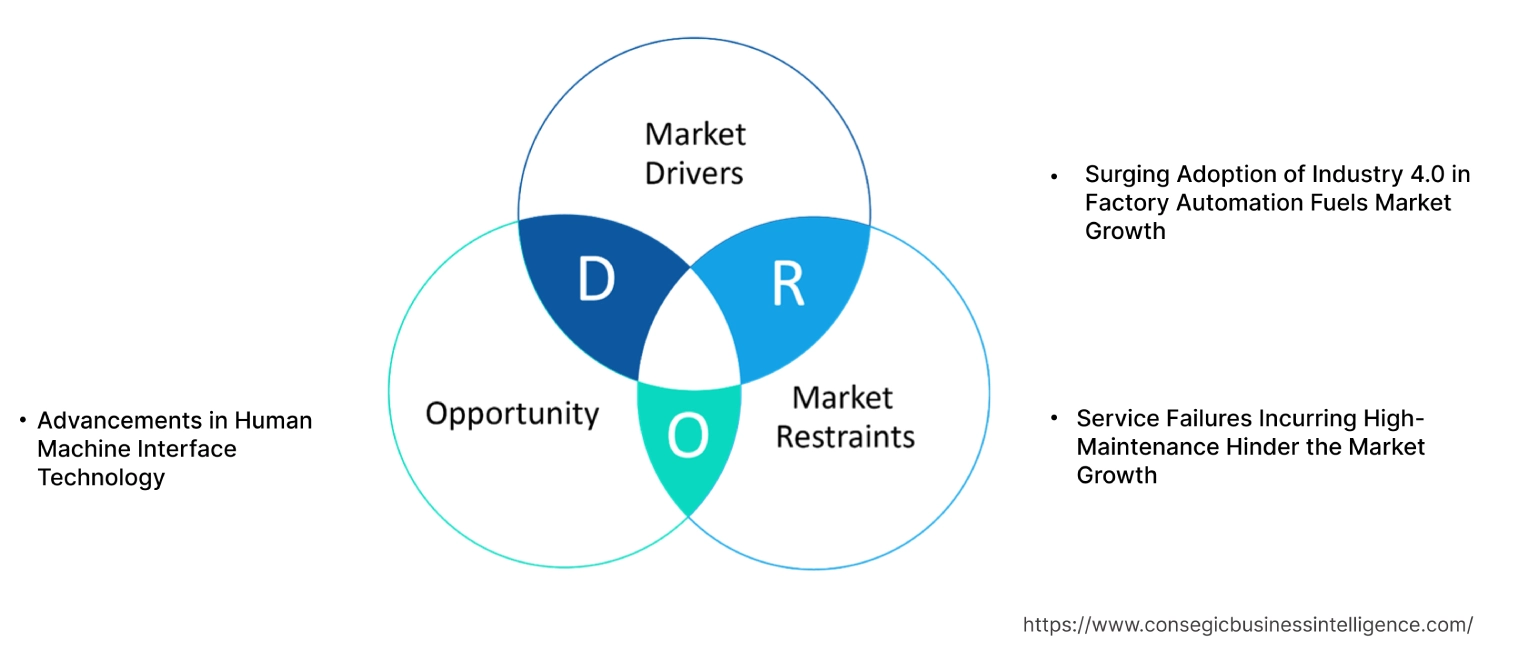

Factory Automation Sensor Market Dynamics - (DRO) :

Key Drivers:

Surging Adoption of Industry 4.0 in Factory Automation Fuels Market Growth

Industry 4.0 refers to smart manufacturing in the factory automation process. It facilitates predictive maintenance, reduces downtime, and contributes to the creation of smart factories where machines interact and adapt to changing conditions. Additionally, smart factories are equipped with advanced sensors, embedded software, and robotics that collect, analyze, and enable decision-making. Moreover, manufacturers are integrating technologies including the Internet of Things (IoT), cloud computing, advanced analytics, AI, and machine learning into their production facilities and throughout their operations.

- In April 2021, Siemens introduced Sitrans SCM IQ IIoT (Industrial Internet of Things) Sensors. These sensors collect data on temperature, pressure, and flow in factory equipment and transmit it to cloud platforms for predictive analytics. This allows manufacturing companies to use real-time data to optimize operations and improve maintenance strategies, significantly reducing downtime.

Therefore, the rising adoption of Industry 4.0 along with emerging technologies including the industrial Internet of Things (IIoT) is propelling the factory automation sensor market growth.

Key Restraints :

Service Failures Incurring High-Maintenance Hinder the Market Growth

Maintenance and reliability issues are significant concerns for factory automation sensors, particularly in demanding industrial environments. Although sensors are engineered to be durable, they are not immune to wear and tear. Factors including temperature extremes, vibration, dust, and exposure to chemicals can degrade sensor performance over time. Regular maintenance is crucial to ensure that sensors operate accurately and reliably. This involves routine inspections, cleaning, calibration, and, when necessary, replacing worn or damaged components. Additionally, sensor failures can lead to significant production delays and downtime, as the affected equipment may need to be shut down for repairs or recalibration. This downtime not only affects productivity but can also incur additional costs for repairs and lost production.

Furthermore, to mitigate these issues, companies implement predictive maintenance strategies. By analyzing sensor data for signs of wear or malfunction, companies anticipate potential failures before they occur, allowing for timely maintenance and minimizing unexpected downtime. Advanced monitoring systems also track the health of sensors and alert maintenance teams to potential issues, enhancing overall reliability and ensuring that the manufacturing process remains smooth and efficient.

- For instance, General Electric (GE) reported issues with a Sensor-Based Gas Turbine Monitoring System in a high-temperature industrial environment. The sensors used to monitor the health and performance of gas turbines experienced degradation due to extreme heat, leading to inaccurate readings. This prompted GE to enhance its predictive maintenance capabilities, including more frequent calibration and the implementation of advanced diagnostics to identify and address sensor wear before it caused significant downtime.

Hence, service failures cause production delays and downtime, restraining the global factory automation sensor market demand.

Future Opportunities :

Advancements in Human Machine Interface Technology

A Human Machine Interface (HMI) is a technology that allows humans to interact with machines, facilitating the control and monitoring of systems through various input and output methods. The factory automation sensors collect the data on multiple parameters and the HMI system displays the real-time data gathered by the sensors. Additionally, these are required to provide real-time data visualization that is easy to comprehend and allows for the control of operating machines with ease. Furthermore, HMIs also enable monitoring and controlling automated systems thereby improving efficiency, increasing productivity, and reducing downtime.

- In March 2023, Rockwell Automation introduced FactoryTalk Optix software designed to enhance human-machine interaction. It provides real-time data visualizations and remote troubleshooting capabilities. Additionally, enables operators to monitor performance metrics and receive contextual information without interrupting production processes.

Thus, as per the analysis, advancements in HMI platforms provide enhanced visualization and interaction, proliferating the factory automation sensor market opportunities.

Factory Automation Sensor Market Segmental Analysis :

By Sensor Type:

Based on the sensor type, the market is segmented into proximity sensor, temperature sensor, pressure sensor, optical sensor, position sensor, flow sensor, level sensor, force sensor, motion sensor, gas sensor, photoelectric sensor, and others.

Trends in the sensor type:

- Level sensors are increasingly being integrated with smart home appliances including refrigerators and washing machines, this trend prevents the liquid level from being too high to overflow.

- Optical sensors are leveraging advancements in light-based detection technologies, including laser and infrared sensors, to enhance detection capabilities and accuracy for various applications.

The temperature sensor type segment accounted for the largest revenue share in 2023.

- A temperature sensor is a thermocouple detector device that provides temperature measurement through an electric signal.

- It consists of contact sensors and non-contact sensors. The contact sensors include thermocouples and thermistors, and the non-contact temperature sensors measure the thermal radiation released by the heat source.

- In October 2021, ABB launched the ABB FusionAir Smart Sensor, a touch-free room sensor with optional room control sensors capable of monitoring the temperature, humidity, carbon dioxide (CO2), and VOCs to improve the overall IAQ and reduce the risk of viral exposure.

- Therefore, the temperature sensor segment is fueling the factory automation sensor market growth.

The motion sensor type segment is anticipated to register the fastest CAGR during the forecast period.

- Motion sensor is a device that detects the movement of an object within its field of view by measuring infrared light emitted.

- These sensors are easy to install, provide accurate information about space utilization, cost-effective, and efficient.

- In October 2022, Bosch unveiled the cost-effective motion sensor BMI323. These sensors are precise, compact, power-efficient, and improve performance.

- Hence, as per the analysis, the ability of motion sensors to detect the movements of objects, is driving the global factory automation sensor market demand.

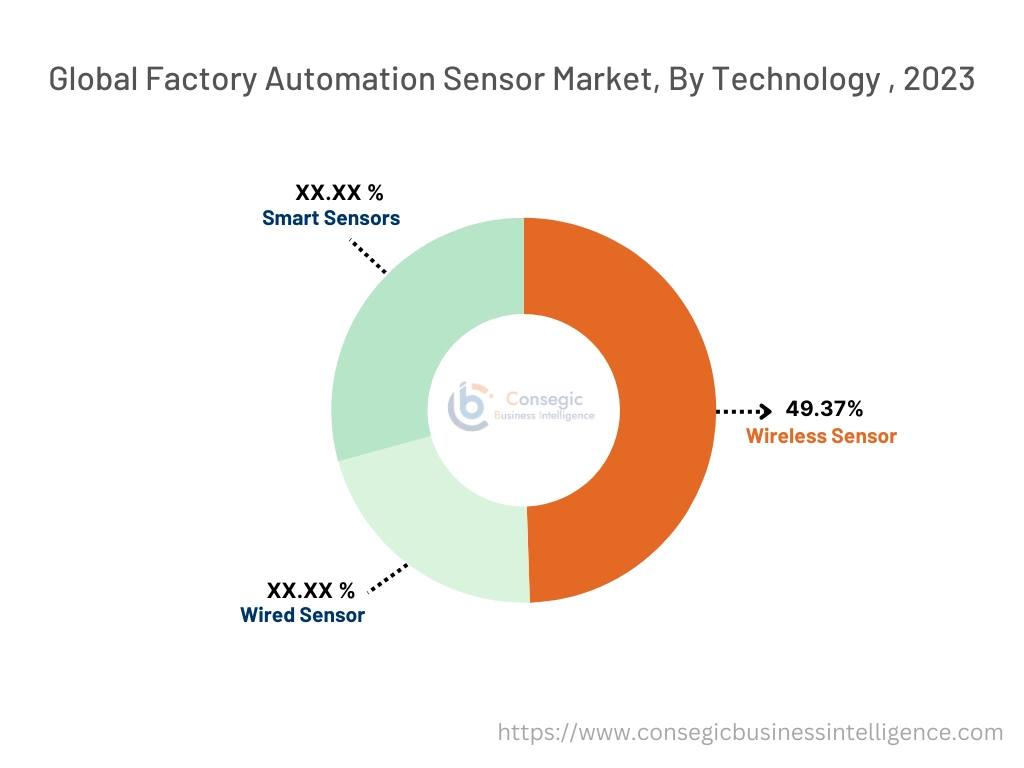

By Technology:

Based on technology, the market is trifurcated into wired sensor, wireless sensor, and smart sensors.

Trends in the technology:

- The rise of the Internet of Things (IoT) is significantly boosting the adoption of wireless sensors. Wireless sensors are integral to IoT networks, providing real-time data without the need for physical connections, this trend enhances system flexibility and scalability.

The biometric-based technology segment accounted for the largest revenue share in the year 2023.

- Modern smart sensors are incorporating self-diagnostic and self-calibration features to ensure optimal performance and reliability. These capabilities reduce the need for manual maintenance and troubleshooting.

The wireless sensor technology segment accounted for the largest revenue share of 49.37% in 2023.

- Wireless technology offers advantages including flexibility and ease of installation.

- These sensors eliminate the demand for extensive cabling, making them ideal for various applications.

- Additionally, these wireless technologies easily integrate with IoT networks, providing real-time data and enabling remote monitoring and control.

- In November 2022, Emerson expanded Rosemount 3051 Pressure Transmitter with Bluetooth wireless technology, for pressure and temperature measurement. The wireless sensors support automation systems, enabling real-time data transmission and enhancing operational efficiency without physical contact.

- Thus, the aforementioned features of wireless sensor technologies are boosting the factory automation sensor market trend.

The smart sensor technology segment is anticipated to register the fastest CAGR during the forecast period.

- Smart sensors are equipped with embedded processing capabilities that allow for on-site data analysis and decision-making.

- It enables more accurate and automated collection of environmental data with less noise.

- These devices are used for monitoring and control mechanisms in various sectors including smart grids, battlefield reconnaissance, and others.

- Additionally, they can interact and integrate with other smart devices and system supports the development of interconnected and intelligent manufacturing environments.

- In November 2021, Endress+Hauser introduced the iTHERM TM411 smart temperature sensor with advanced diagnostics and self-calibration features. This sensor improves accuracy, reduces maintenance needs in process industries and efficiently integrates with smart devices.

- Therefore, as per the analysis, the advanced monitoring and control of smart sensors is fueling opportunities for the factory automation sensor market share.

By End User:

Based on end-user the market is segmented into automotive, electronics, pharmaceutical, energy and power, food and beverages, oil and gas, aerospace, healthcare, and others.

Trends in the end-user :

- The trend towards smaller and more compact electronic devices is driving the development of miniaturized sensors that can fit into tight spaces while providing accurate measurements.

- Sensors are vital for ensuring food safety and quality throughout processing and packaging. They monitor parameters such as temperature, humidity, and contamination levels to prevent spoilage and ensure compliance with safety standards.

The automotive end-user segment accounted for the largest revenue share in the year 2023 and is anticipated to register the fastest CAGR during the forecast period.

- The automotive sector is increasingly integrating advanced sensors into automobiles to streamline manufacturing processes.

- Sensors used in collision avoidance, lane-keeping, and adaptive cruise control are driving the market in this segment.

- Additionally, there is a significant growth for sensors in automotive safety features including Advanced Driver Assistance Systems (ADAS).

- In September 2022, Continental launched Modular multi-sensors that integrate advanced technologies for commercial vehicle safety and automation. This includes sensors for detecting environmental conditions and vehicle status, which are essential for implementing and improving safety features and autonomous driving capabilities.

- Consequently, as per the analysis, the sensors provide automotive safety features in the sector is propelling the factory automation sensor market.

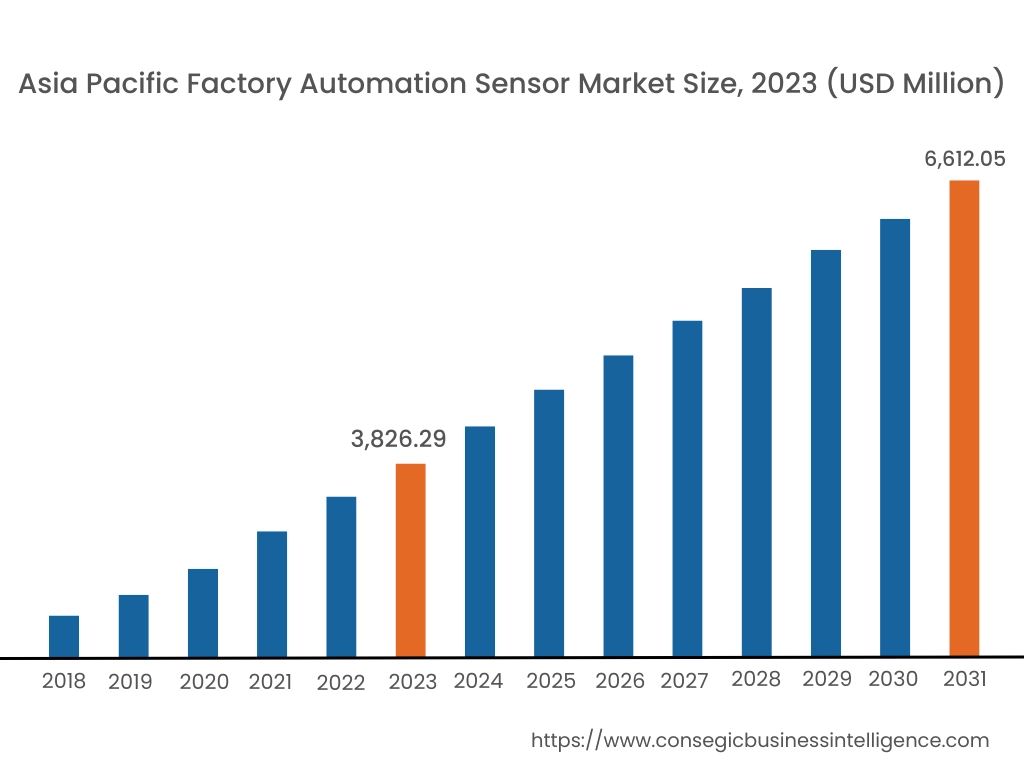

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 3,826.29 Million in 2023. Moreover, it is projected to grow by USD 4,024.66 Million in 2024 and reach over USD 6,612.05 Million by 2031. Out of this, China accounted for the maximum revenue share of 29.3%. According to factory automation sensor market analysis, Asia-Pacific countries including China, India, Japan, and South Korea are experiencing rapid industrialization. This growth is driving significant investments in automation technologies, including advanced sensors, to enhance manufacturing efficiency and productivity.

- For instance, Keyence (Japan) launched the LM-X series a multisensor measurement system that provides high-accuracy measurement with a built-in low-pressure touch probe enabling 3D inspection of three-dimensional parts. High-accuracy optical image measurement is achieved with the ultra-high resolution 20-megapixel CMOS sensor.

North America is estimated to reach over USD 8,382.95 Million by 2031 from a value of USD 4,993.94 Million in 2023 and is projected to grow by USD 5,240.03 Million in 2024. North America, particularly the United States and Canada, is a leader in adopting and implementing advanced technologies, including factory automation sensors. The region's focus on Industry 4.0 and smart manufacturing has led to significant investments in automation technologies.

- In June 2023, Honeywell (US) launched the DG Smart Sensor, designed to provide improved efficiency and reliability in monitoring and controlling pressure. It offers precise monitoring capabilities and supports the digitalization trends along with Industry 4.0 and smart manufacturing.

Europe is a significant player in the factory automation sensor market, with strong contributions from countries including Germany, France, and Italy. The region is established in manufacturing base with rising adoption of Industry 4.0 drives demand for factory automation sensors.

In Latin America, the factory automation sensor market, the growth is gradually expanding as the region is adopting industrial modernization. Countries including Brazil, Mexico, and Argentina are at the forefront of the development. The Middle East and Africa region is witnessing a steady rise in the adoption of factory automation sensors fueled by the oil and gas sector.

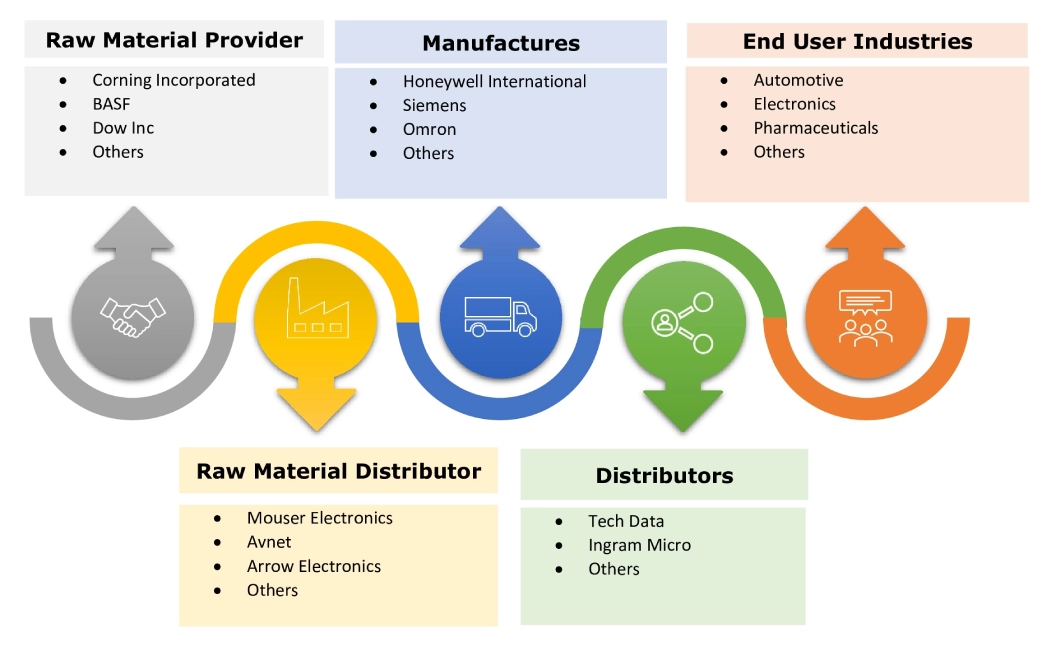

Top Key Players & Market Share Insights:

The factory automation sensor market is highly competitive with major players providing sensory features for automation to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the factory automation sensor market. Key players in the factory automation sensor industry include-

- Rockwell Automation (US)

- Emerson Electric Co. (US)

- National Instruments (US)

- Siemens (Germany)

- Schneider Electric (France)

- Omron Corporation (Japan)

- Hikvision (China)

- TX Sensors (US)

- Honeywell International Inc. (US)

- Keyence Corporation (Japan)

- Yokogawa Electric Corporation (Japan)

- SICK AG (Germany)

- ABB Ltd. (Switzerland)

Recent Industry Developments :

Product Launch:

- In April 2023, Siemens expanded Siemens Smart Infrastructure by launching SIBushing, a sensor bushing, protection, and indication device. It is designed to enhance the reliability and efficiency of industrial operations. These sensors provide advanced protection solutions for high-voltage applications.

- In April 2023, Omron launched NX-Series NX502 automation controllers with enhanced safety control. It is designed to enhance the processing speed and precision of automation systems, catering to the needs of complex industrial needs. It integrates seamlessly with various sensors and devices, enabling real-time data collection and processing for improved decision-making and operational efficiency.

- In February 2023, Omron introduced the K7DD-PQ Series for condition monitoring using conventional vibration sensors. It enables operators to monitor motor equipment conditions and view anomalies locally. K7DD-PQ is equipped with 50-ms operating speed and the capacity to calculate over 400 types of feature values, allowing them to identify many different failure modes of motors.

Factory Automation Sensor Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 25,083.64 Million |

| CAGR (2024-2031) | 6.7% |

| By Sensor Type |

|

| By Technology |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the factory automation sensor market? +

Factory Automation Sensor Market size is estimated to reach over USD 25,083.64 Million by 2031 from a value of USD 14,877.69 Million in 2023 and is projected to grow by USD 15,616.51 Million in 2024, growing at a CAGR of 6.7% from 2024 to 2031.

What is the key market trend? +

The trend towards smaller and more compact electronic devices is driving the development of miniaturized sensors that can fit into tight spaces while providing accurate measurements.

What is a factory automation sensor? +

Factory automation sensor refers to the devices in industrial settings that are used to collect data on various physical parameters including temperature, pressure, motion, and proximity. It converts physical phenomena into measurable digital signals which are then displayed enabling operators to read and proceed further.

Which region/country is anticipated to witness the highest CAGR during the forecast period, 2023-2031? +

Asia Pacific is anticipated to register the fastest CAGR growth during the forecast period. Due to rapid industrialization and investments in automation technologies, including advanced sensors, to enhance manufacturing efficiency and productivity.