Fluoropolymer Processing Aid Market Size:

Fluoropolymer Processing Aid market size is growing with a CAGR of 2.6% during the forecast period (2025-2032), and the market is projected to be valued at USD 1.92 Billion by 2032 from USD 1.57 Billion in 2024. Additionally, the market value for 2025 is attributed to USD 1.61 Billion.

Fluoropolymer Processing Aid Market Scope & Overview:

Fluoropolymer Processing Aids (FPA) are specialized additives, that are used in very small amounts into thermoplastic resins during their processing. Their primary function is to improve the flow and surface properties of the polymer melt by drifting to the interface between the polymer and the metal surfaces of the processing equipment. This forms a thin, low-friction coating that effectively lubricates the die surface. The key benefits of these additives include the elimination of melt fractures, reduction of die build-up, and overall enhancement of processing efficiency. This leads to improved product quality, increased throughput, lower energy consumption, and reduced scrap rates, ultimately contributing to cost savings in manufacturing operations. They are widely used in the production of films, wires, cables, pipes, and other extruded or molded plastic products across diverse industries.

Fluoropolymer Processing Aid Market Dynamics - (DRO) :

Key Drivers:

The Rise in Production of Plastic Packaging to Propel the Fluoropolymer Processing Aid Market Growth.

As industries increasingly require durable materials for packaging solutions that offer enhanced protection, extended shelf life, and improved aesthetics, the use of high-performance polymers like polyethylene (PE) and polypropylene (PP) in rigid and flexible packaging applications is surging. FPAs are crucial in this context because they optimize the manufacturing process of these plastics, preventing defects like melt fracture, reducing die build-up, and improving the overall surface quality, gloss, and clarity of the final packaging products.

For instance,

- According to the data published by the U.S. Plastics Pact Inc, in 2022, states that the U.S. Pact's consumer packaged goods, retailer, and converter Activators produce 5.8 million metric tons of plastic packaging annually, accounting for 33% of all plastic packaging by weight in the U.S.

Thus, the rise in the production of plastic packaging by various end users is propelling the fluoropolymer processing aid market demand.

Key Restraints:

Stringent Regulations to Hinder Fluoropolymer Processing Aid Market Expansion.

The global fluoropolymer processing aid industry faces a significant restraint in the form of stringent regulations. These regulations, mainly driven by growing concerns over environmental impact, human health, and safety, impose considerable hurdles for manufacturers. As many commonly used processing aids contain PFAS, growing concerns over their environmental persistence and potential health issues are influencing global regulatory bodies, such as the U.S. Environmental Protection Agency (EPA) and the European Chemicals Agency (ECHA), to implement stricter controls, restrictions, and even outright bans on their production, use, and disposal. As a result, the above-mentioned factors limit the fluoropolymer processing aid market demand.

Future Opportunities :

Rise in Production of Electric Vehicles to Create Fluoropolymer Processing Aid Market Opportunities.

As EVs become increasingly prevalent, there is a growing requirement for high-performance polymer components that are lightweight, durable, and possess excellent thermal and electrical insulation properties. Fluoropolymer processing aids are crucial in manufacturing these advanced plastics for EV applications, allowing smoother extrusion, reducing melting fracture, and improving the overall quality of critical components such as battery packs, wiring and cables, fuel cell membranes, and various seals and gaskets that demand superior resistance to heat, chemicals, and wear. The rise in the production of electric vehicles is further influencing the use of this additive.

For instance,

- The data by IEA states that, in 2024, global electric car production surged to 17.3 million units, representing a substantial one-quarter increase compared to the previous year. This significant growth is largely fueled by China's robust manufacturing output, which alone accounted for 12.4 million electric cars.

Thus, as per the market analysis, the rise in production of electric vehicles is expected to create fluoropolymer processing aid market opportunities.

Fluoropolymer Processing Aid Market Segmental Analysis :

By Polymer Type :

Trends in Polymer Type:

- The fluoropolymer processing aid market trends are influenced by the growing demand for polyethylene for improved processing efficiency and final product quality, particularly in films and cables.

The Polyethylene (PE) segment accounted for the largest market share in 2024 and is expected to grow at the fastest CAGR over the forecast period.

- As one of the most widely produced and utilized polymers globally, particularly in various forms like LLDPE, HDPE, and LDPE, polyethylene demands processing aids to enhance its manufacturing efficiency and end-product quality.

- These additives are crucial in PE processing to reduce common issues such as melt fracture, reduce die build-up, lower extrusion pressure, and ultimately increase throughput.

- The sheer volume of PE used in applications ranging from packaging films, wires and cables, pipes and tubes, and various consumer goods, fuels the consistent and substantial demand for FPAs.

- Various manufacturers are focusing on expanding their polyethylene units because of their wide use.

- For instance, in 2023, Baystar officially launched its new Bay 3 polyethylene unit, marking a significant advancement in the production of high-performance polyethylene (PE) and enhanced sustainability.

- Thus, as per the market analysis, the aforementioned factors are influencing the segment.

By End Use:

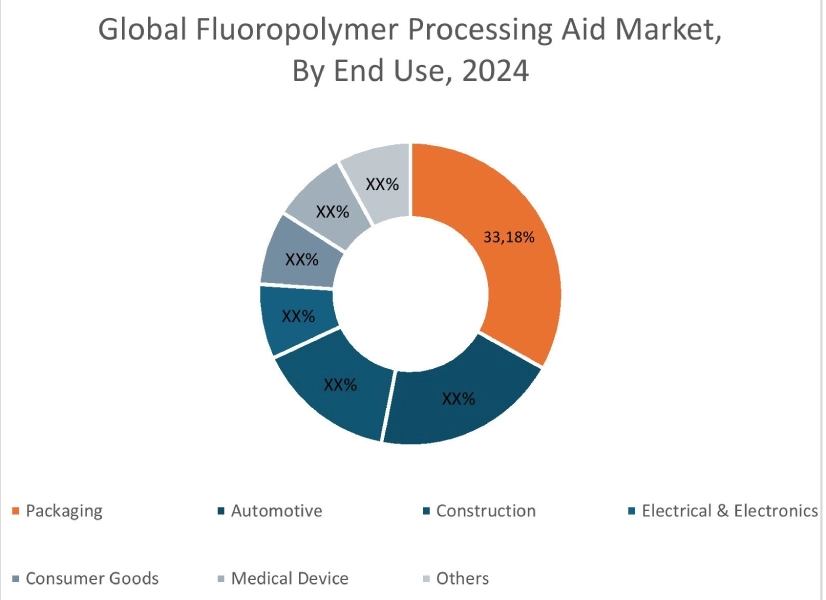

Based on end use, the market is categorized into packaging, automotive, construction, electrical & electronics, consumer goods, medical devices, and others.

Trends in the End Use:

- The key trend for packaging in the market is the growing requirement for high-performance, and lightweight materials for various packaging applications.

- An increase in trend for lightweight materials for efficient automotives is influencing the use of high-performance compounds.

The packaging segment accounted for the largest Fluoropolymer Processing Aid market share of 33.18% in 2024.

- Packaging stands as a pivotal end use sector for fluoropolymer processing aids due to the critical role these additives play in enhancing the manufacturing of various plastic packaging materials.

- These additives are widely employed, particularly in the production of blown and cast films, which are foundational to flexible packaging, food and beverage containers, and other consumer goods packaging.

- By reducing melt fracture, minimizing die build-up, improving surface smoothness, and allowing faster production speeds, FPAs contribute significantly to the quality, efficiency, and cost-effectiveness of packaging film extrusion.

- This results in clearer, stronger, and more aesthetically appealing packaging that meets the stringent requirements for product protection, visual appeal, and high-speed processing in the global packaging market.

- Thus, as per the market analysis, the adoption of packaging is influencing segment share.

The automotives segment is expected to grow at the fastest CAGR over the forecast period.

- The automotive sector represents a growing end-use segment for fluoropolymer processing aids due to the increasing requirement for high-performance plastics and lightweight materials in modern vehicles, including the rapidly expanding electric vehicle (EV) sector.

- These additives play a crucial role in enhancing the processing of various polymers like polyethylene and polypropylene used in automotive components.

- They allow manufacturers to produce higher quality parts such as fuel system components, electrical system components, seals, gaskets, and various interior and exterior trim elements more efficiently.

- This not only contributes to the overall durability, safety, and performance of vehicles, including improved fuel efficiency and reduced emissions through lightweighting, but also helps to optimize manufacturing processes by increasing throughput and reducing waste.

- The rise in the use of these additives in vehicles, including light vehicles, offers enhanced features, thus leading to a rise in production.

- For instance, according to the data provided by TD Economics in April 2024, the U.S. light vehicle market, saw a 12.7% increase in sales.

- Hence, owing to the above-mentioned analysis, the automotive segment is expected to grow at the fastest rate over the future years, creating fluoropolymer processing aid market trends.

Regional Analysis:

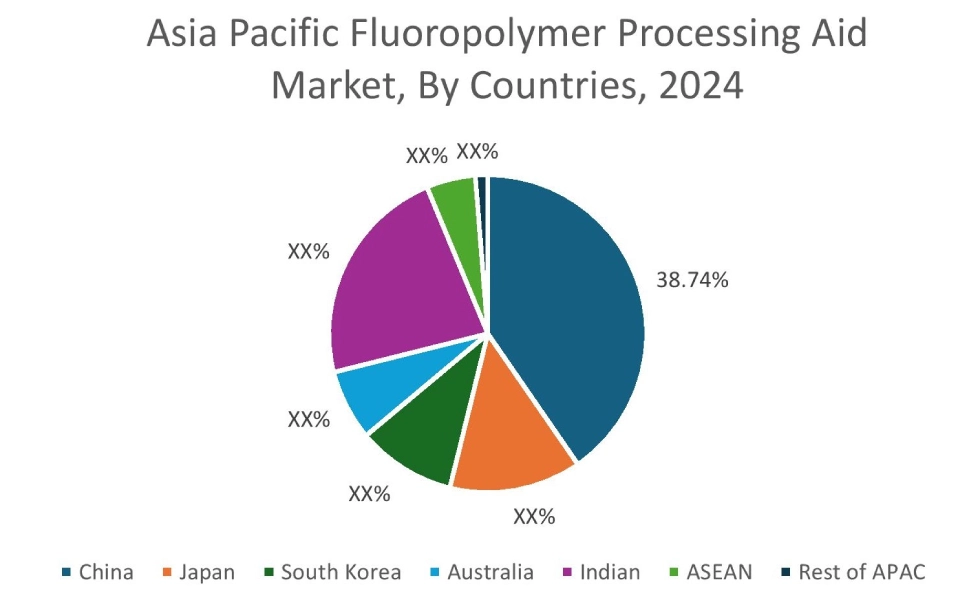

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

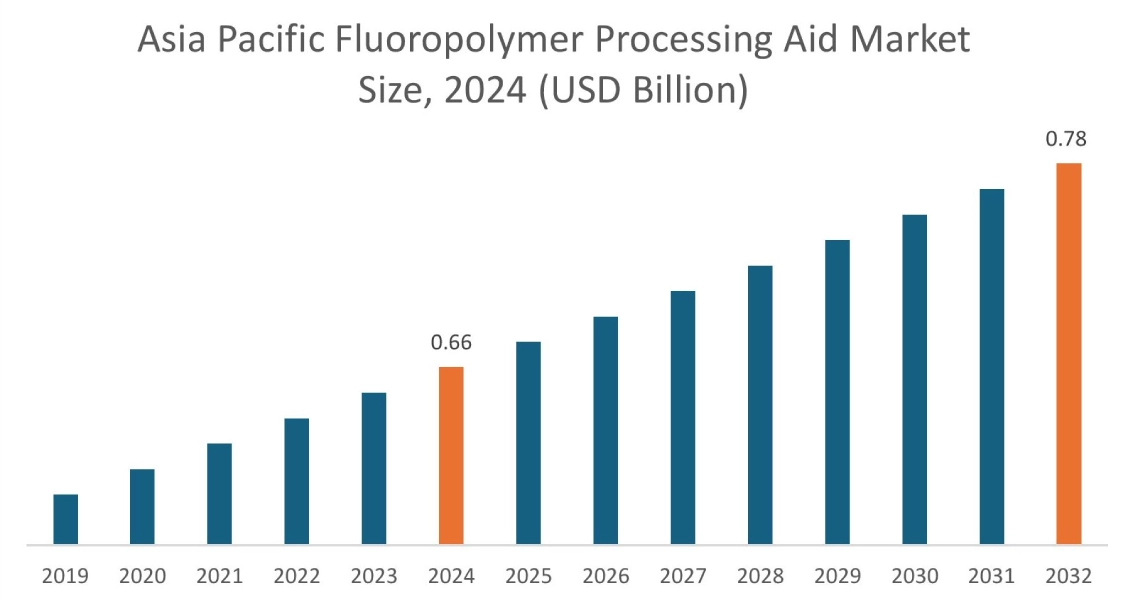

In 2024, Asia Pacific accounted for the highest Fluoropolymer Processing Aid market share at 42.13% and was valued at USD 0.66 Billion and is expected to reach USD 0.78 Billion in 2032. In Asia Pacific, China accounted for a market share of 38.74% during the base year of 2024. This significant requirement for packaged goods, particularly flexible packaging, necessitates efficient and high-quality polymer processing, making fluoropolymer processing aids increasingly crucial. These additives are widely used to enhance the extrusion of plastics materials such as polyethylene and polypropylene for films and other packaging materials, addressing issues such as melt fracture, reducing die build-up, improving surface finish, and increasing throughput, ultimately leading to better product quality and more cost-effective production in the region's vast packaging sector. The rise in the packaging sector in this region is influencing the use of these additives.

For instance,

- The data by Packaging Industry Association of India, states that Packaging is India's fifth major economic sector, growing rapidly at a 26.7% CAGR between 2020 and 2025.

Thus, as per the fluoropolymer processing aid market analysis, these factors create a strong upward trajectory for the Asia Pacific market, positioning it as a key region for players.

In Europe, the industry is experiencing the fastest growth with a CAGR of 3.5% over the forecast period. Europe is a growing market for electric vehicles, with a strong push towards electrification driven by stringent emission regulations, government incentives, and increasing consumer awareness of sustainability. This growing EV sector in Europe, with its requirement for high-performance and durable components, directly fuels the need for fluoropolymer processing aids. These additives are important in manufacturing various EV components, including high-voltage cables and wire insulation, battery separators, and seals, by improving the processability of the polymers used, eliminating defects like melt fracture, and enhancing the overall quality, safety, and longevity of these critical parts. Thus, as per the fluoropolymer processing aid market analysis, the growing trend for adoption of electric vehicles is driving the trends of the market in this region.

The North American region is seeing substantial growth in both residential and non-residential segments, including transportation, energy, and public facilities. Within this expanding landscape, fluoropolymer processing aids play a crucial role. These aids are utilized in the manufacturing of various plastic components used in construction, such as PVC pipes and profiles, wires and cables for electrical systems, and high-performance films for building envelopes. Thus, as per the market analysis, the rise in the construction sector is propelling the fluoropolymer processing aid market expansion in this region.

The medical device sector in Latin America is experiencing significant growth, driven by an aging population, rising prevalence of chronic diseases, increasing healthcare expenditure, and a growing emphasis on technological advancements and consumer health awareness. FPAs are essential in the manufacturing of the high-performance polymers, that are extensively used in medical applications such as catheters, surgical tubing, implantable devices, and laboratory equipment. Thus, these aforementioned factors are contributing to the market growth in this region.

The consumer goods sector in the Middle East and Africa (MEA) region is experiencing significant growth, driven by factors such as rapid urbanization, a rising middle class with increasing disposable incomes, and a significant population with evolving preferences. Fluoropolymer processing aids are becoming increasingly vital in the MEA region. FPAs are crucial for enhancing the efficiency and quality of plastic processing, particularly for polyethylene and polypropylene used extensively in consumer goods packaging, films, and various molded parts. Thus, the aforementioned factors are influencing the fluoropolymer processing aid market growth in this region.

Top Key Players and Market Share Insights:

The Global Fluoropolymer Processing Aid Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Fluoropolymer Processing Aid market. Key players in the Fluoropolymer Processing Aid industry include

- HTC Corporation (China)

- Make Real (UK)

- Arkema (France)

- Guangzhou Shine Polymer Material Co., Ltd (China)

- Shanghai Lanpoly Polymer Technology Co., Ltd. (China)

- 3M (U.S.)

- Pure Polymers (U.S.)

- Ultraleap (UK)

- Solvay (Belgium)

- AGC Chemicals (U.S.)

- Daikin America, Inc (U.S.)

Fluoropolymer Processing Aid Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1.92 Billion |

| CAGR (2025-2032) | >2.6%/td> |

| By Polymer Type |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Fluoropolymer Processing Aid market? +

In 2024, the Fluoropolymer Processing Aid market is USD 1.57 Billion.

Which is the fastest-growing region in the Fluoropolymer Processing Aid market? +

Europe is the fastest-growing region in the Fluoropolymer Processing Aid market.

What specific segmentation details are covered in the Fluoropolymer Processing Aid market? +

By Polymer Type, and End Use segmentation details are covered in the Fluoropolymer Processing Aid market.

Who are the major players in the Fluoropolymer Processing Aid market? +

Arkema (France), Guangzhou Shine Polymer Material Co., Ltd (China), Shanghai Lanpoly Polymer Technology Co., Ltd. (China) are some of the major players in the market.