Cyclic Olefin Polymer Market Size:

Cyclic Olefin Polymer Market size is growing with a CAGR of 5.8% during the forecast period (2025-2032), and the market is projected to be valued at USD 1.61 Billion by 2032 from USD 1.03 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 1.09 Billion.

Cyclic Olefin Polymer Market Scope & Overview:

Cyclic olefin polymer (COPs), also called cyclo olefin polymer is a class of amorphous, high-performance thermoplastics. They are primarily made via ring-opening metathesis polymerization (ROMP) of cyclic olefins such as norbornene, followed by hydrogenation. They boast exceptional properties such as high transparency (glass-like clarity), low birefringence, high heat resistance (high glass transition temperature), excellent chemical resistance, low moisture absorption, high rigidity, and good dimensional stability. They also exhibit low extractables and leachables, making them very pure. They are used in applications such as packaging, medical devices, optical lenses, and various electronic components needing high performance.

Key Drivers:

Increasing Demand from the Medical Sector is Accelerating Cyclic Olefin Polymer Market Expansion.

Cyclic olefin polymer is highly valued in the medical sector due to its unique combination of properties that make it ideal for sensitive applications. Their glass-like transparency and high purity are critical for diagnostic devices such as microfluidic chips, cuvettes, and biochips, enabling accurate analysis and preventing interference with samples. They also exhibit excellent chemical resistance to various reagents and biocompatibility. This ensures they do not react with drugs or biological fluids. Additionally, their high heat resistance allows for common sterilization methods such as autoclaving, while their dimensional stability ensures precision in drug delivery systems such as pre-filled syringes and vials, providing a safer and more reliable alternative to glass. The increasing prevalence of chronic diseases has led to sector growth, hence requiring these polymers for multiple applications.

For instance,

- In 2024, Nipro Medical Corporation, a global leader in medical devices, announced a major expansion, the opening of its first North American manufacturing facility, thus positively impacting cyclic olefin polymer market trends.

Overall, the increasing need from the medical sector is significantly boosting the cyclic olefin polymer market expansion.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Cyclic Olefin Polymer Market Demand.

The market faces hurdles from the substitutes available in the market. For instance, polycarbonate offers excellent impact strength and toughness. This makes it ideal for applications requiring robust durability. It also boasts high transparency, and good heat resistance, and is compatible with various sterilization methods, leading to widespread use in medical device housings, transparent protective shields, and some optical lenses. Moreover, polymethyl methacrylate (PMMA) is known for its superior optical clarity (often exceeding glass), good scratch resistance, and lower cost. It's lightweight and easy to process, making it highly suitable for applications such as optical lenses, display screens, lighting diffusers, and certain medical components (e.g., dental prosthetics, and intraocular lenses). Additionally, polysulfone (PSU) and polyphenylsulfone (PPSU) polymers offer exceptional high-temperature performance and hydrolytic stability, allowing them to withstand repeated steam sterilization cycles (autoclaving) without significant degradation. Hence, the growing commercialization of substitutes is hampering the cyclic olefin polymer market demand.

Future Opportunities :

Expanding Electronics Sector is Expected to Cyclic Olefin Polymer Market Opportunities.

Cyclic olefin polymer is known for its low dielectric constant and loss tangent. This makes them excellent electrical insulators, crucial for high-frequency applications such as 5G components, antennas, and high-speed circuit boards, minimizing signal loss. Moreover, these properties enable the precise fabrication of intricate micro-channels and structures for biochips and diagnostic devices. Additionally, in MEMS and microfluidics, they provide excellent chemical resistance to a wide range of solvents and acids, high purity (low extractable), and superior dimensional stability are paramount. Rising digitalization has led to increased demand for electronics, hence positively influencing the cyclic olefin polymer market trends.

For instance,

- According to Electronics Era, the global MEMS industry from 2023 to 2029 is expected to grow at a CAGR of 5%. This creates the potential for the market.

Overall, the expanding electronics sector is expected to increase the cyclic olefin polymer market opportunities.

Cyclic Olefin Polymer Market Segmental Analysis :

By Type:

Based on type, the market is categorized into homopolymers and copolymers.

Trends in Type:

- There is a growing trend of pharmaceutical packaging shifting from traditional materials such as glass to cyclic olefin which is a copolymer type due to their lower breakage risk and reduced interaction with drug formulations.

- The usage of cyclic olefin homopolymer-based in advanced electronics and optics due to their superior transparency is also a rising trend.

The copolymers segment accounted for the largest market share in 2024

- Cyclic olefin copolymer (COC) are polymers formed by the copolymerization of cyclic olefin monomers with acyclic olefins, typically ethylene.

- They offer a broad spectrum of benefits such as their ability to adjust the monomer ratio allows for control over properties such as glass transition temperature, flexibility, and toughness.

- They have low moisture absorption which prevents dimensional changes and maintains material integrity in humid environments.

- Additionally, they are resistant to a wide range of acids, alkalis, and polar solvents. All these factors are driving their increased usage in multiple sectors such as packaging, medical, electronics, and others.

- Overall, as per the market analysis, the aforementioned factors are driving a segment in the market.

The homopolymers segment is expected to grow at the fastest CAGR over the forecast period.

- Cyclic olefin homopolymers properties are solely derived from the structure of this singular cyclic monomer, resulting in very specific characteristics.

- They are also known for very low extractables and leachables, essential for sensitive applications where interaction with the material must be minimized.

- They exhibit excellent light transmission and very low birefringence, often making them as clear as glass. This makes them useful in industries such as electronics and optical. Growth in these industries is driving segmental share.

- For instance, Samsung Display plans to increase its AMOLED panel production by 10% in 2025,focusing on high-value products such as tablets and foldable displays.

- Overall, as per the market analysis, the aforementioned factors will drive a segment in the cyclic olefin polymer market growth.

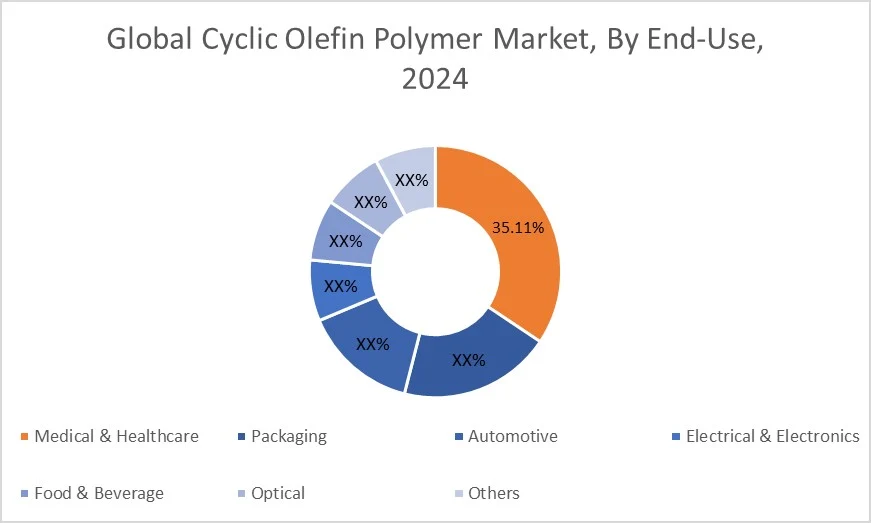

By End-Use:

Based on end-use, the market is categorized into medical & healthcare, packaging, automotive, electrical & electronics, food & beverage, optical, and others.

Trends in the End-Use

- There is a growing trend of using cyclo olefin polymer in pre-filled syringes, vials, and cartridges due to their superior purity, and break resistance.

- The usage of cyclo olefin polymers in automotive LiDAR cameras for ADAS and head-up display components is also a rising trend.

The medical & healthcare segment accounted for the largest market share of 35.11% in 2024.

- COPs are used in syringes, vials, and diagnostic containers, replacing glass due to their breakage resistance and lighter weight.

- They are also utilized in microfluidic devices, lab-on-a-chip technology, and optosensors.

- They are also chosen for drug delivery systems, including prefilled syringes, due to their inertness, barrier properties, and ability to withstand sterilization.

- They are particularly useful for sensitive pharmaceuticals such as protein or peptide-based drugs. The increase of the pharmaceutical industry is driving the segment

- For instance, according to the Government of India, in the fiscal year 2023-24, India’s pharma sector's turnover continued its steady growth, expanding at over 10% annually for the past five years.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the cyclic olefin polymer industry.

The electrical & electronics segment is expected to grow at the fastest CAGR over the forecast period.

- COPs are used in electronics due to their high transparency and low birefringence, which enhances efficiency and picture quality.

- Their low dielectric constant and good high-frequency performance make them ideal for antenna substrates, connectors, and semiconductor encapsulation materials in 5G and other advanced communication technologies.

- Moreover, in micro-electro-mechanical systems (MEMS), their ultra-high purity, chemical resistance, and ability to be precisely molded into intricate micro-structures are crucial.

- This allows for the fabrication of advanced bio-chips, sensors, and microfluidic devices where precision, inertness, and reliability are essential for performance, hence creating the potential for the segment.

- Thus, according to market analysis, the aforementioned factors will drive the segment in the cyclic olefin polymer market growth.

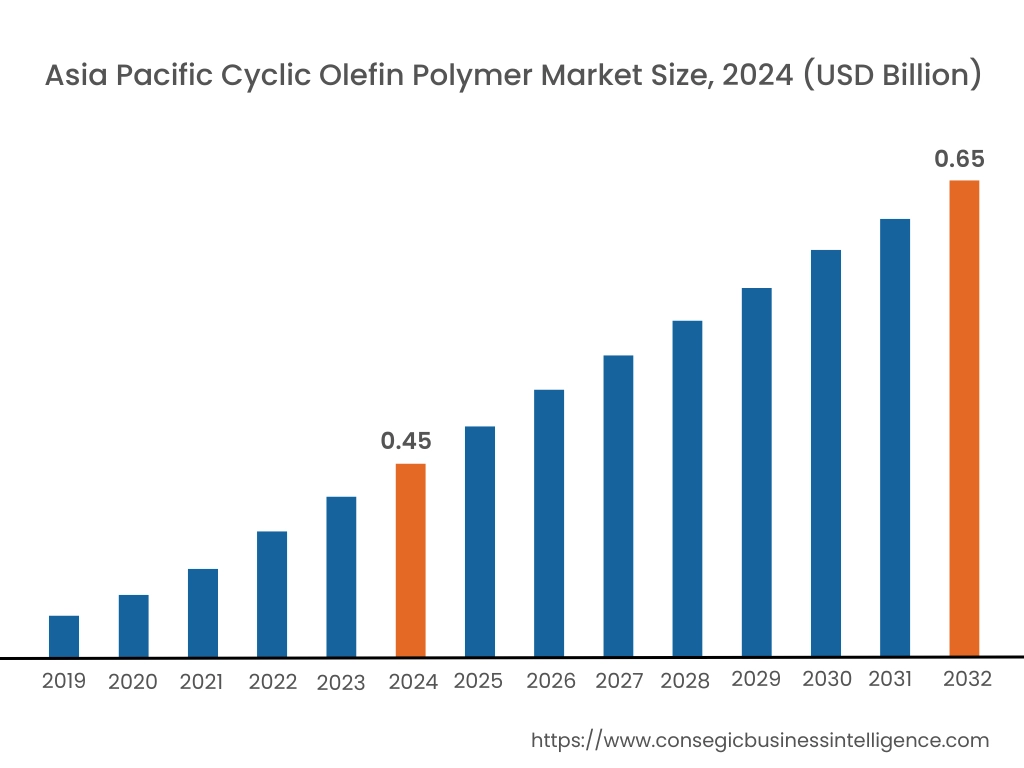

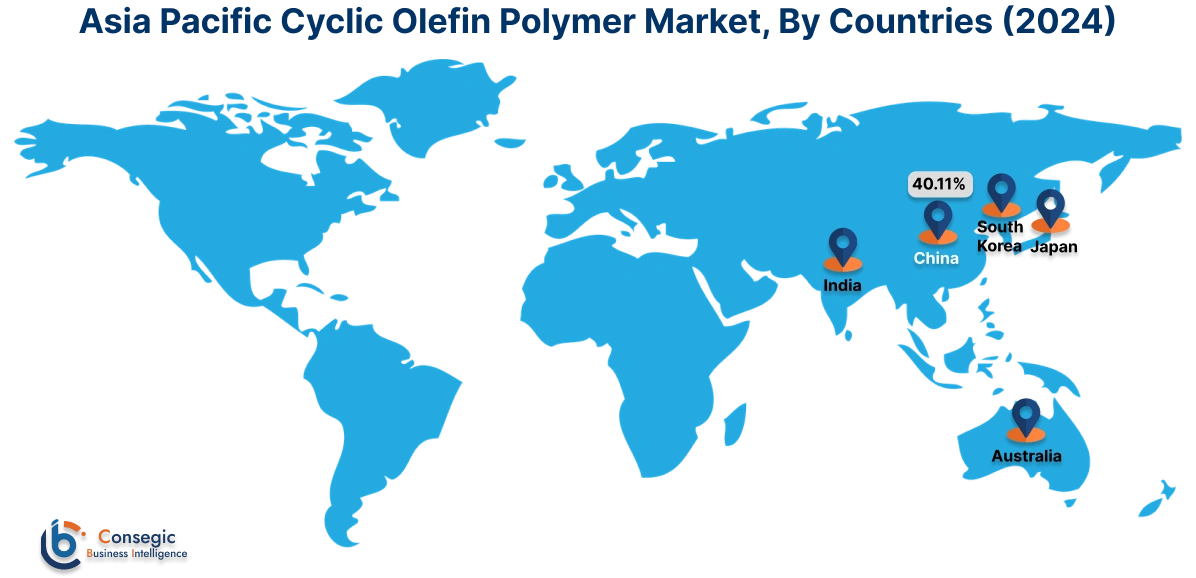

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest cyclic olefin polymer market share at 43.16% and was valued at USD 0.45 Billion and is expected to reach USD 0.65 Billion in 2032. In Asia Pacific, the China accounted for the cyclic olefin polymer market share of 40.11% during the base year of 2024. There is a rapidly growing pharmaceutical and healthcare domain in the region. This is driven by aging populations, rising prevalence of chronic diseases, and increasing healthcare expenditure. Countries such as India, China, and South Korea lead the market.

For instance,

- According to Atradius Group, China's pharmaceuticals and healthcare sector is experiencing robust growth, with a strong performance for both 2022 and 2023. Over the broader 2019-2025 period, the sector is forecast to achieve an impressive CAGR of 9.4%.

Cyclic olefin polymer is used for multiple applications. Its ultra-high purity, excellent moisture and oxygen barrier properties, and low extractables/leachables make it indispensable for packaging sensitive drugs, vaccines, and biologics in applications such as pre-filled syringes, vials, and blister packs, ensuring drug stability and extended shelf life. Overall, the growing pharma and healthcare sector is driving the market in the region.

In Europe, the cyclic olefin polymer market is experiencing the fastest growth with a CAGR of 7.8% over the forecast period. There is growing demand for sophisticated electronics in the region. The region's robust innovation ecosystem fosters the development of advanced consumer electronics, industrial automation systems, and high-tech communication infrastructure. Cyclic olefin polymer offers exceptional properties, such as its low dielectric constant and loss tangent, making it ideal for high-frequency circuit boards and components crucial for 5G technology. Furthermore, thermal stability is vital for display technologies, camera lenses in smartphones, and sensors, ensuring precision and reliability in Europe's cutting-edge electronic devices.

North America’s cyclic olefin polymer market analysis indicates that several key trends are contributing to its growth in the region. The automotive industry is rapidly expanding in countries such as the U.S. and Canada. The rapid integration of advanced driver-assistance systems (ADAS), autonomous driving features, and sophisticated in-cabin electronics demand high-performance materials. Cyclic olefin polymer provides superior optical clarity, low birefringence, and thermal stability and is crucial for lenses in LiDAR systems, automotive cameras, head-up displays (HUDs), and interior sensors. Additionally, its lightweight nature and dimensional stability contribute to overall vehicle efficiency and safety, meeting the stringent requirements of North American automotive innovation.

Middle East and Africa (MEA) cyclic olefin polymer market analysis indicates that there is a growing packaging sector. Rising disposable incomes, urbanization, and changing consumer lifestyles are fueling the consumption of packaged food, beverages, pharmaceuticals, and personal care products. Cyclo olefin polymer provides excellent barrier properties against moisture and oxygen, coupled with its high purity and clarity, make it ideal for extending the shelf life and ensuring the safety of sensitive products. Its usage in pharmaceutical blister packs and high-performance food packaging addresses the region's evolving need for reliable and safe packaging solutions.

Latin America's region creates potential for the market. The optical sector is transforming into the region. Increasing urbanization and access to technology are boosting the need for high-quality optical components across various applications. Cyclo olefin polymer offers exceptional transparency, low birefringence, and high heat resistance making it an ideal material for precision optical lenses in cameras (including smartphones), projectors, and emerging Augmented Reality (AR)/Virtual Reality (VR) devices. As the region's consumer electronics and industrial imaging markets expands, the need for these polymers to produce high-performance, lightweight, and durable optical elements will continue to rise.

Top Key Players and Market Share Insights:

The Cyclic Olefin Polymer market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Cyclic Olefin Polymer market. Key players in The Cyclic Olefin Polymer industry include-

- TOPAS Advanced Polymers GmbH (Germany)

- Mitsui Chemicals, Inc. (Japan)

- Zeon Corporation (Japan)

- Sumitomo Bakelite Co., Ltd. (Japan)

- JSR Corporation (Japan)

- Tuoxin Technology (China)

- Biosynth (Switzerland)

- INEOS Olefins & Polymers Europe (Switzerland)

- Asahi Kasei Corporation (Japan)

- Borealis AG (Austria)

Cyclic Olefin Polymer Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1.61 Billion |

| CAGR (2025-2032) | 5.8% |

| By Type |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Cyclic Olefin Polymer market? +

In 2024, the Cyclic Olefin Polymer market is USD 1.03 Billion.

Which is the fastest-growing region in the Cyclic Olefin Polymer market? +

Europe is the fastest-growing region in the Cyclic Olefin Polymer market.

What specific segmentation details are covered in the Cyclic Olefin Polymer market? +

Type and End-Use segmentation details are covered in the Cyclic Olefin Polymer market.

Who are the major players in the Cyclic Olefin Polymer market? +

TOPAS Advanced Polymers GmbH (Germany), Mitsui Chemicals, Inc. (Japan), Zeon Corporation (Japan), Sumitomo Bakelite Co., Ltd. (Japan), and JSR Corporation (Japan) are some major players in the market.