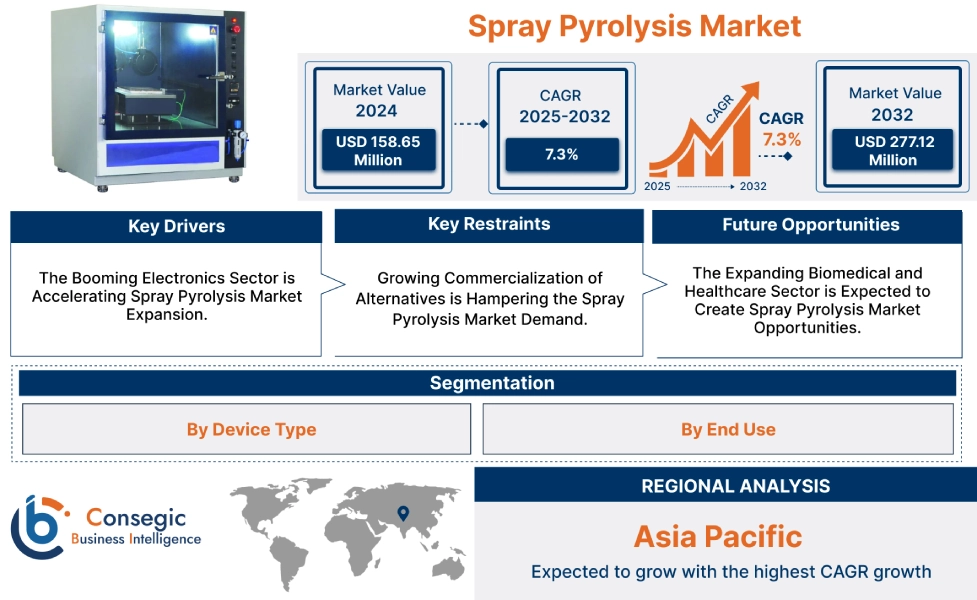

Spray Pyrolysis Market Size:

Spray Pyrolysis Market size is growing with a CAGR of 7.3% during the forecast period (2025-2032), and the market is projected to be valued at USD 277.12 Million by 2032 from USD 158.65 Million in 2024. Additionally, the market value for the 2025 attributes to USD 169.61 Million.

Spray Pyrolysis Market Scope & Overview:

Spray pyrolysis is a cost-effective and versatile thin-film deposition technique used to create uniform coatings, films, or powders. It involves spraying a liquid solution containing precursor chemicals onto a heated substrate. The process begins with dissolving desired chemical compounds (precursors) in a suitable solvent to create a solution. This solution is then atomized (broken into fine droplets) by a spray nozzle (e.g., ultrasonic, pneumatic, or electrostatic). These droplets are propelled towards a heated substrate, where the solvent evaporates, and the precursors undergo thermal decomposition (pyrolysis) to form the desired solid material. By-products are typically volatile and escape. Its benefits include low cost, simplicity, scalability for large areas, non-vacuum requirement, and the ability to deposit a wide range of materials (especially metal oxides).

Key Drivers:

The Booming Electronics Sector is Accelerating Spray Pyrolysis Market Expansion.

Spray pyrolysis plays a significant role, particularly in the fabrication of various thin films and functional layers for electronic devices. It is used to deposit uniform and high-quality thin films of semiconducting metal oxides and transparent conductive oxides. It offers a low-cost, non-vacuum, and scalable alternative to more expensive and complex vacuum-based deposition techniques such as PVD and CVD, making it attractive for large-area semiconductor applications. These films are crucial for manufacturing components such as thin-film transistors (TFTs) found in displays, as well as various types of sensors (gas sensors, biosensors) where precise material properties are required. Increasing demand across various sectors, such as AI and autonomous vehicles, is driving semiconductor manufacturing, hence market growth.

For instance,

- According to the United States International Trade Commission, Taiwan's semiconductor industry output between 2018 and 2022 grew at a CAGR of 17.04%, thus positively impacting spray pyrolysis market trends.

Overall, the booming electronics sector is significantly boosting the spray pyrolysis market expansion.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Spray Pyrolysis Market Demand.

The market faces hurdles from the substitutes available in the market. For instance, chemical vapor deposition offers excellent film uniformity, high purity, conformal coating of complex geometries, and superior control over film composition and microstructure. It produces high-quality films for advanced semiconductor devices and protective coatings where precise atomic-level control is crucial. Moreover, physical vapor deposition provides very high film purity, excellent adhesion, and the ability to deposit a vast range of materials (metals, alloys, nitrides, oxides). PVD techniques offer precise thickness control and are crucial for applications such as hard coatings, optical coatings, and semiconductor metallization, where high density and specific crystalline structures are required. Additionally, the sol-gel method is a low-cost, low-temperature process that allows for excellent control over chemical composition at the molecular level, and it can cover large and complex surfaces. Sol-gel is particularly strong in synthesizing hybrid organic-inorganic materials and producing highly homogeneous thin films and powders with tailored optical and catalytic properties. Hence, the growing commercialization of substitutes is hampering the spray pyrolysis market demand.

Future Opportunities :

The Expanding Biomedical and Healthcare Sector is Expected to Create Spray Pyrolysis Market Opportunities.

Spray pyrolysis is finding increasing relevance in the biomedical and healthcare sectors due to its ability to precisely engineer materials. It is becoming vital for drug delivery systems to synthesize nanoparticles that encapsulate drugs for targeted release, minimizing side effects. Moreover, its role in creating functional layers for advanced diagnostic tools like lab-on-a-chip devices enables highly sensitive and rapid detection of diseases, paving the way for personalized medicine and point-of-care diagnostics. For biocompatible coatings on implants, it allows the deposition of thin, inert, or even bioactive layers such as hydroxyapatite or bioglass on medical devices such as orthopedic implants and stents, improving integration with the body and reducing rejection. Increasing demand for healthcare services has led to sector increase, hence positively influencing spray pyrolysis market trends.

For instance,

- According to the International Trade Administration, the medical device industry of China is expected to grow at a CAGR of 8.3% from 2021 to 2026, creating potential for the market.

Overall, the expanding biomedical and healthcare sectors are expected to increase the spray pyrolysis market opportunities.

Spray Pyrolysis Market Segmental Analysis :

By Device Type:

Based on device type, the market is categorized into ultrasonic, high-throughput, flame-assisted, vacuum spray, pneumatic, and others.

Trends in Device Type:

- There is a growing trend of using ultrasonic systems due to their ability to produce exceptionally fine and uniform droplets, crucial for high-quality, precise thin films and nanoparticles.

- Automation is a key trend across all device types, with systems offering programmable spray patterns and precise control over parameters to enhance reproducibility and reduce human error.

The ultrasonic segment accounted for the largest market share in 2024

- Ultrasonic is currently the dominant device type in the market. Its dominance stems from its ability to generate extremely fine and uniform droplets using high-frequency ultrasonic vibrations.

- This precision leads to high film quality, excellent uniformity, and controlled particle proportions, which are critical for challenging applications in electronics, nanotechnology, and energy storage, including the synthesis of high-purity nanoparticles and thin films. Growth of these industries is driving the segmental share.

- For instance, according to the Energy Information Administration, the U.S. has seen a continuous increase in battery storage capacity since 2021, with projections indicating an impressive 89% surge by the close of 2024.

- Overall, as per the market analysis, the aforementioned factors are driving a segment in the market.

The flame-assisted segment is expected to grow at the fastest CAGR over the forecast period.

- Flame-assisted is an advanced variant of the traditional spray pyrolysis technique that incorporates a flame to enhance the thermal decomposition of precursor solutions.

- In this method, the fine droplets generated from the precursor solution are passed through or directly exposed to a high-temperature flame before or during their deposition onto a heated substrate.

- The flame provides an additional, often higher, energy input, leading to more complete and rapid pyrolysis of the precursors.

- This allows for better control over the material's crystallinity, density, and adhesion to the substrate, enabling the synthesis of a wider range of materials, including complex metal oxides and ceramics. All these benefits are driving its increased usage.

- Overall, as per the market analysis, the aforementioned factors will drive a segment in the spray pyrolysis market growth.

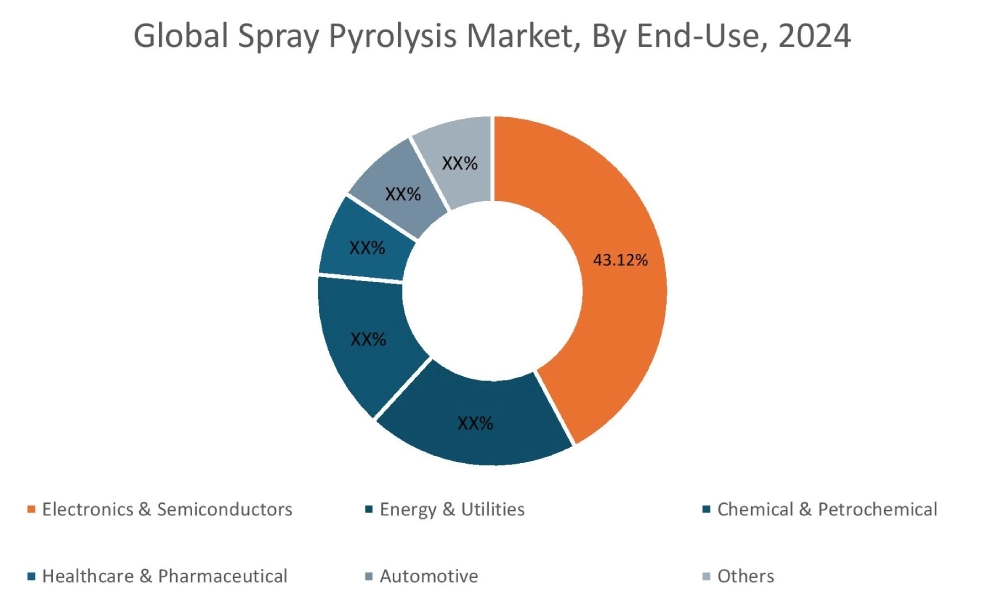

By End Use:

Based on end-use, the market is categorized into electronics & semiconductors, energy & utilities, chemical & petrochemical, healthcare & pharmaceutical, automotive, and others.

Trends in the End-Use

- There is a growing trend of using spray pyrolysis in synthesizing nanoparticles for targeted drug delivery systems and creating biocompatible coatings for medical implants.

- The electrification of vehicles is increasing the demand for spray pyrolysis in creating advanced coatings for EV battery components, sensors, and functional surfaces within automotive electronics.

The electronics & semiconductors segment accounted for the largest market share of 43.12% in 2024.

- The electronics & semiconductors end-use sector dominates the market. This supremacy stems from the sector’s incessant need for high-performance, miniaturized, and cost-effective components.

- Spray pyrolysis is crucial for depositing transparent conductive oxides (TCOs) such as ITO and FTO, essential for displays, touchscreens, and various optoelectronic devices.

- The ability of spray pyrolysis to produce uniform films over large areas at atmospheric pressure, reducing production costs compared to vacuum-based methods, makes it the preferred choice for mass manufacturing in this rapidly expanding industry.

- For instance, according to IBEF, the Indian electronics sector grew by 16.88% from 2015 to 2023.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the spray pyrolysis industry.

The healthcare & pharmaceutical segment is expected to grow at the fastest CAGR over the forecast period.

- The healthcare & pharmaceutical sector represents a significant emerging end-use for the market.

- This growth is driven by advancements in medical technology and the increasing demand for novel material solutions.

- Spray pyrolysis is gaining traction for synthesizing nanoparticles for targeted drug delivery systems, enabling precise drug release and improved therapeutic efficacy while minimizing side effects.

- It is also vital for creating biocompatible and functional coatings for medical implants (e.g., orthopedic implants, stents), enhancing their integration with biological tissues and reducing the risk of rejection or infection. All these benefits are driving their increased usage in the sector.

- Thus, according to market analysis, the aforementioned factors will drive the segment in the spray pyrolysis market growth.

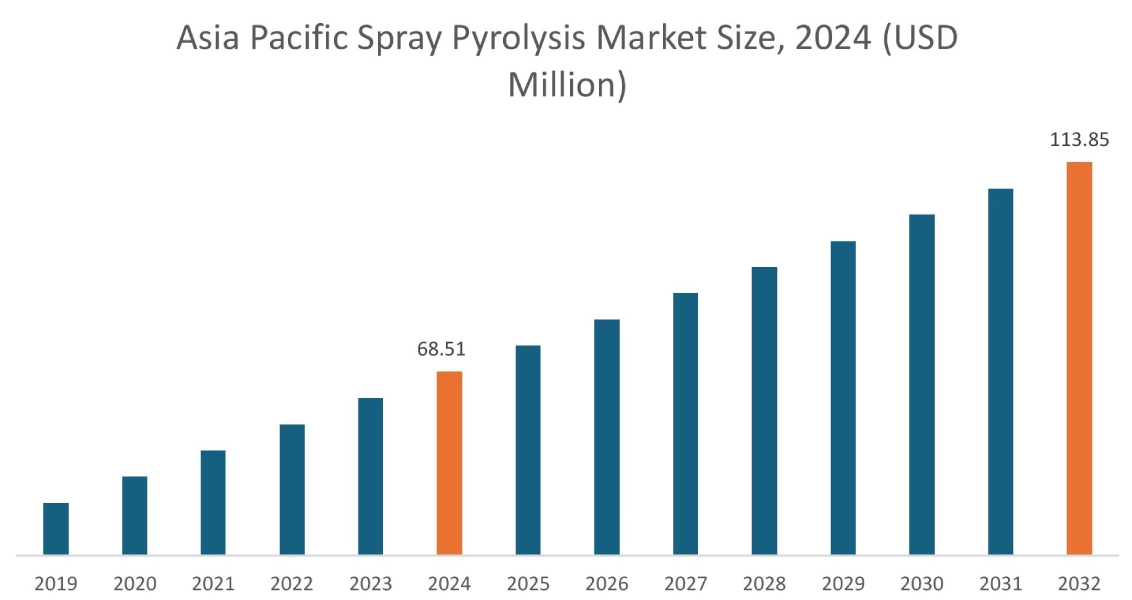

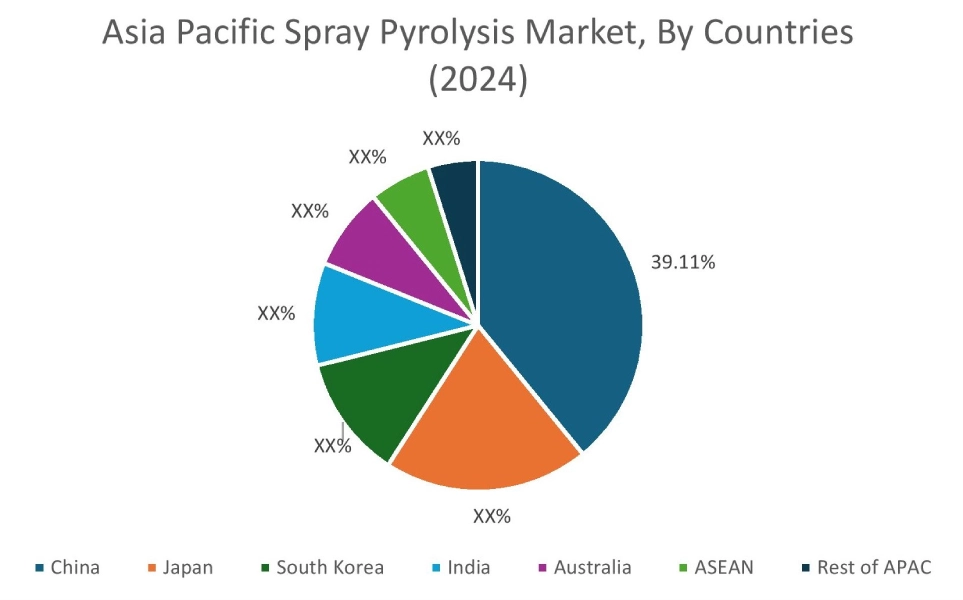

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest spray pyrolysis market share at 43.18% and was valued at USD 68.51 Million, and is expected to reach USD 113.85 Million in 2032. In Asia Pacific, China accounted for the spray pyrolysis market share of 39.11% during the base year of 2024. The region is a hub for electronics production. This surge is driven by increasing urbanization, rising disposable incomes, and the widespread adoption of smart devices, 5G technology, and IoT. Countries such as India, China, Japan, and South Korea lead the market.

For instance,

- According to the Semiconductor Association, China's expanded wafer capacity represented 26% of the global increase.

Spray pyrolysis plays a significant role in electronics production, particularly in the creation of thin films and nanomaterials used in various electronic components. It's a versatile and scalable technique for depositing materials with precise control over morphology, composition, and structural properties. Overall, the growing electronics production is driving the market in the region.

In Europe, the spray pyrolysis market is experiencing the fastest growth with a CAGR of 8.6% over the forecast period. There is a growing solar sector in the region. The EU aims for at least 700 GW of new solar capacity by 2030, a fourfold increase from 2020. This rapid increase creates a significant need for efficient and cost-effective solar cell manufacturing. Spray pyrolysis offers substantial benefits for this European solar boom. It is a low-cost, scalable, and versatile technique for depositing thin films for various solar cell types, including perovskites and CIGS. Its ability to create uniform films over large areas and its compatibility with flexible substrates make it ideal for mass production, supporting Europe's goal to accelerate solar deployment and potentially re-shore manufacturing.

North America’s spray pyrolysis market analysis indicates that several key trends are contributing to its growth in the region. It is significantly propelled by continuous technological advancements. The region's robust R&D infrastructure, particularly in the US and Canada, fosters innovation in material science and nanotechnology. This includes developing more precise ultrasonics for controlled nanoparticle and thin-film synthesis, enhancing automation and software integration for improved reproducibility, and exploring smart coatings. These advancements cater to the high demand of North American industries such as healthcare (e.g., biosensors, drug delivery) and advanced materials for electric vehicles, driving the adoption of sophisticated solutions.

Middle East and Africa (MEA) spray pyrolysis market analysis indicates that there is a growing chemical sector in the region. This is driven by rapid industrialization, diversification strategies away from oil, and increasing demand from expanding end-use industries such as construction, automotive, and packaging. Spray pyrolysis offers substantial benefits to this burgeoning chemical landscape. It provides a cost-effective and scalable method for synthesizing high-purity chemicals, catalysts, and advanced coatings. Its ability to create uniform thin films for sensors, produce nanoparticles for enhanced material properties, and contribute to environmentally friendly processes aligns perfectly with the MEA chemical sector's push for innovation, efficiency, and sustainability.

Latin America's region creates potential for the market. There is significant growth in the automotive sector. This is driven by increasing vehicle sales, particularly in Brazil and Argentina, and a rising focus on local production of hybrid and electric vehicles. Spray pyrolysis offers notable advantages for this evolving automotive landscape. It enables the deposition of high-quality thin films for various applications, including anti-corrosion coatings for vehicle bodies, functional layers for sensors (e.g., oxygen, NOx sensors), and transparent conductive oxides for displays and smart windows. Its cost-effectiveness and ability to produce uniform coatings efficiently support the scaling up of local production in Latin American-manufactured vehicles.

Top Key Players and Market Share Insights:

The Spray Pyrolysis market is highly competitive, with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Spray Pyrolysis market. Key players in the Spray Pyrolysis industry include-

- Holmarc Opto-Mechatronics Ltd. (India)

- Siansonic (China)

- Cheersonic Ultrasonic Equipments Co., Ltd. (China)

- Navson Technologies Pvt. Ltd. (India)

- Shanghai Huashao Intelligent Equipment Co., Ltd. (China)

- Sono-Tek Corporation (United States)

- MTI Corporation (United States)

- Hansun (China)

- Acmefil Engineering Systems Pvt. Ltd. (India)

- Zhengzhou CY Scientific Instrument Co., Ltd. (China)

Spray Pyrolysis Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 277.12 Million |

| CAGR (2025-2032) | 7.3% |

| By Device Type |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Spray Pyrolysis market? +

In 2024, the Spray Pyrolysis market is USD 158.65 Million.

Which is the fastest-growing region in the Spray Pyrolysis market? +

Europe is the fastest-growing region in the Spray Pyrolysis market.

What specific segmentation details are covered in the Spray Pyrolysis market? +

Device Type and End-Use segmentation details are covered in the Spray Pyrolysis market.

Who are the major players in the Spray Pyrolysis market? +

Holmarc Opto-Mechatronics Ltd. (India), Sono-Tek Corporation (United States), MTI Corporation (United States), Hansun (China), Acmefil Engineering Systems Pvt. Ltd. (India), Zhengzhou CY Scientific Instrument Co., Ltd. (China), and Siansonic (China) are some major players in the market.