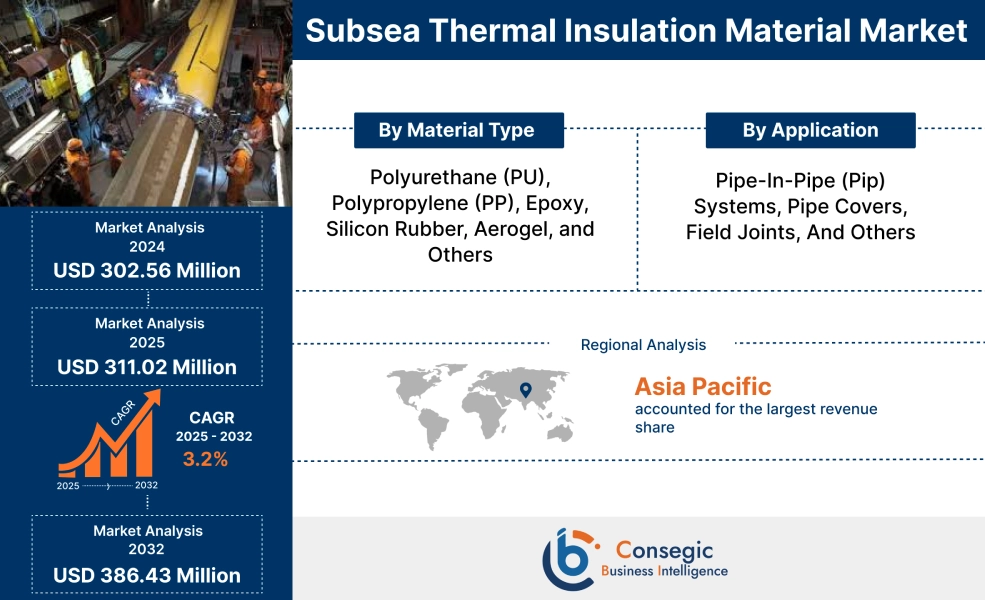

Subsea Thermal Insulation Material Market Size:

The Subsea Thermal Insulation Material Market size is growing with a CAGR of 3.2% during the forecast period (2025-2032), and the market is projected to be valued at USD 386.43 Million by 2032 from USD 302.56 Million in 2024. Additionally, the market value for 2025 is attributed to USD 311.02 Million.

Subsea Thermal Insulation Material Market Scope & Overview:

Subsea Thermal Insulation Material materials are specialized coatings and systems that are engineered mainly for the protection of oil & gas pipelines, risers, and other subsea equipment from extreme temperatures. Their main purpose is to maintain the temperature of transported hydrocarbons above critical levels, mainly for preventing the formation of hydrates and wax plugs that hinder or block the flow. These materials, mainly composed of polymers such as polyurethane, polypropylene (PP), epoxy, silicon rubber, aerogel, and others are applied to ensure efficient flow assurance, reduce energy losses, and safeguard the integrity and operational lifespan of vital subsea infrastructure in challenging deepwater environments.

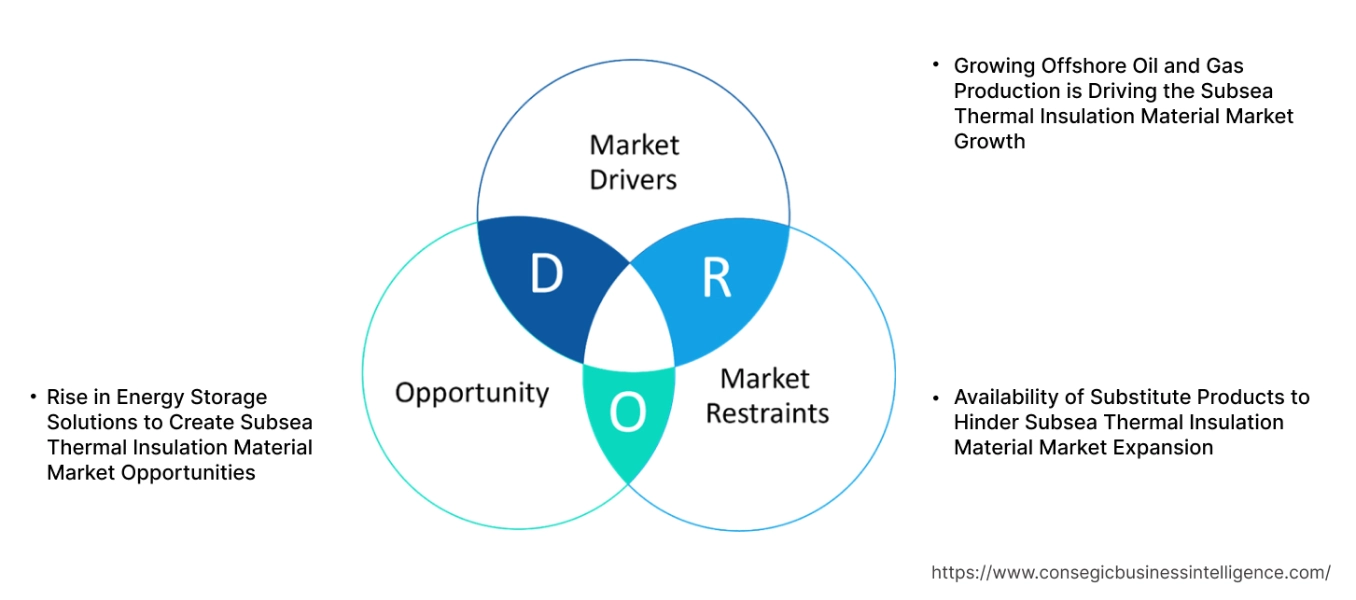

Subsea Thermal Insulation Material Market Dynamics - (DRO) :

Key Drivers:

Growing Offshore Oil and Gas Production is Driving the Subsea Thermal Insulation Material Market Growth.

As easily accessible onshore and shallow-water reserves deplete, oil and gas companies are increasingly entering into more challenging environments, mainly deepwater and ultra-deepwater regions. These extreme operational conditions introduce complex engineering challenges that make Subsea Thermal Insulation Material not just beneficial, but absolutely critical for the safe, efficient, and continuous flow of hydrocarbons. The growth in the production of crude oil and gas from offshore sites is influencing the use of this solution.

For instance,

- In 2022, EIA, oil and natural gas production in the Federal Offshore Gulf of America accounted for about 15% of total U.S. crude oil production and about 2% of total U.S. dry natural gas production.

Hence, due to the aforementioned factors, growing need for electronics is driving the development of the market.

Key Restraints:

Availability of Substitute Products to Hinder Subsea Thermal Insulation Material Market Expansion.

The Subsea Thermal Insulation Material market faces significant headwinds from stringent regulatory standards, particularly those governing the oil and gas industry's environmental impact, operational safety, and material performance in deepwater environments. Regulations from government bodies impose rigorous requirements on the materials used in subsea infrastructure. These include demands for proven long-term performance under extreme pressures and temperatures, resistance to chemical degradation, fire safety, and environmental compatibility in case of leaks or failures. Compliance necessitates extensive and costly material qualification, validation testing, certifications, and often requires the use of specialized, high-performance insulation solutions that meet specific thermal efficiency and durability thresholds. This regulatory burden increases research and development costs for manufacturers, lengthens the time-to-market for new insulation technologies, and adds to the overall project expenses for oil and gas operators, thereby acting as a significant restraining factor on the market growth.

Future Opportunities :

Rise in Energy Storage Solutions to Create Subsea Thermal Insulation Material Market Opportunities.

The global energy landscape is undergoing a significant shift, characterized by an accelerating shift towards renewable sources and focus on energy storage solutions. This fundamental redirection of how energy is generated, transmitted, and consumed is not only impacting terrestrial infrastructure but is also creating significant and growing opportunities within the market. Traditionally, Subsea Thermal Insulation Material has been critical for the oil and gas industry, primarily to ensure flow assurance in pipelines carrying hydrocarbons from deepwater wells. Maintaining the temperature of oil and gas prevents the formation of hydrates and wax deposits that block flowlines, thus ensuring operational efficiency and preventing costly shutdowns. However, the growing investments in offshore renewable energy and rise in energy storage obligations are now diversifying the Subsea Thermal Insulation Material Market demand.

For instance,

- According to the MINISTRY OF NEW AND RENEWABLE ENERGY, the energy storage obligations are expected to increase by 0.5% on a yearly basis by 2030

Thus, due to the aforementioned factors, trends in energy storage systems create Subsea Thermal Insulation Material market opportunities.

Subsea Thermal Insulation Material Market Segmental Analysis :

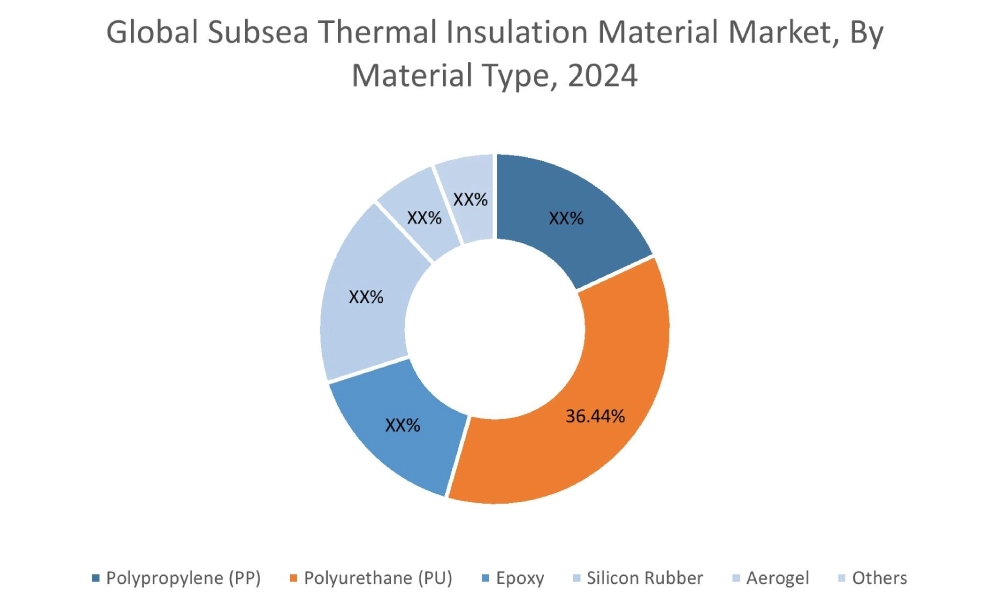

By Material Type:

Based on material type, the market is categorized into Polyurethane (PU), Polypropylene (PP), Epoxy, Silicon Rubber, Aerogel, and Others

Trends in Material Type:

- The exceptional mechanical strength and adhesion properties are influencing the use of polyurethane in insulation applications.

- The growing trend for innovation and high-performance insulation solutions is influencing the use if aerogels.

The polyurethane (PU) segment accounted for the largest Subsea Thermal Insulation Material market share of 36.44% in 2024

- Polyurethane (PU) is a polymer composed of organic units joined by urethane links.

- It is formed by the reaction of a polyol and a diisocyanate or polyisocyanate, in the presence of various additives and catalysts.

- The use of Polyurethane (PU) as a raw material is important in Subsea Thermal Insulation Material due to its exceptional properties critical for deepwater oil and gas operations.

- PU offers high mechanical strength, allowing it to withstand the significant forces exerted by the deep-sea environment, while its excellent adhesion to steel pipes ensures long-term integrity.

- Thus, as per the market analysis, the growth in the use of polyurethane is driving the Subsea Thermal Insulation Material market growth in this region.

The Aerogel segment is expected to grow at the fastest CAGR over the forecast period.

- Aerogel stands as an innovative raw material for Subsea Thermal Insulation Material due to its unparalleled properties, making it ideal for the extremely challenging deep-water oil and gas environments.

- This synthetic porous ultralight material, derived from a gel where the liquid component has been replaced with gas, claims the lowest thermal conductivity of any known solid.

- In subsea applications, particularly for pipe-in-pipe (PIP) systems carrying hydrocarbons from wells to platforms, maintaining fluid temperature is critical to prevent the formation of hydrates or wax that leads to blockages and flow assurance issues.

- Manufacturers are introducing novel aerogel insulation plants to expand their aerogel technology.

- For instance, in 2024, Armacell, a global leader in flexible foam for the equipment insulation market and a leading provider of engineered foams, announced the launch of its new cutting-edge aerogel technology in Asia aims in accelerating the launch of this new product platform, which will significantly expand the company’s aerogel-based ArmaGel portfolio.

- Thus, as per the market analysis, based on the above-mentioned factors, the aerogel segment dominates as well as is expected to grow at the fastest CAGR in the Subsea Thermal Insulation Material market demand.

By Application:

The application is categorized into pipe-in-pipe (PiP) systems, pipe covers, field joints, and others.

Trends in the Application

- The continuous expansion and upkeep of the vast global network of pipelines ensure a steady and high demand for field joints, securing their large market share in terms of both volume and value.

- Modern offshore projects operate under higher pressures and temperatures, demanding an additional layer of structural integrity and insulation that PiP systems effectively offer.

The field joints segment accounted for the largest Subsea Thermal Insulation Material market share in 2024.

- Field joints are important for connecting pipe segments on-site during pipeline construction.

- Because of the vast global network of pipelines being laid, maintained, and repaired, the sheer volume and continuous need for reliable connections make field joints a consistently dominant segment.

- Every single pipe connection requires a simple pipeline requires a field joint.

- The rise in the production of oil and natural gas production is influencing the use of this solution.

- The data published in EIA, states that S. oil and natural gas production both increased in 2023 compared to 2022. Oil production rose from 12.2 million barrels per day in December 2022 to 13.3 million barrels per day in December 2023.

- Their widespread application across all types of piping projects, new builds, extensions, and repairs, ensures their large market share in terms of volume and value.

- Thus, as per the market analysis, the aforementioned factors are driving the Subsea Thermal Insulation Material market expansion.

The pipe-in-pipe (PiP) systems segment is expected to grow at the fastest CAGR over the forecast period.

- PiP systems are emerging as the fastest-growing segment, particularly in challenging environments such as deepwater and ultra-deepwater subsea oil and gas extraction, as well as in applications requiring superior thermal management or enhanced protection.

- PiP systems are important for maintaining the temperature of fluids (like oil and gas) in cold environments, preventing hydrate and wax formation that block pipelines.

- Modern offshore projects involve higher pressures and temperatures, requiring robust solutions that PiP systems provide by offering an additional layer of structural integrity and insulation.

- Thus, based on the market analysis, the pipe-in-pipe (PiP) systems segment is the fastest growing segment in the industry.

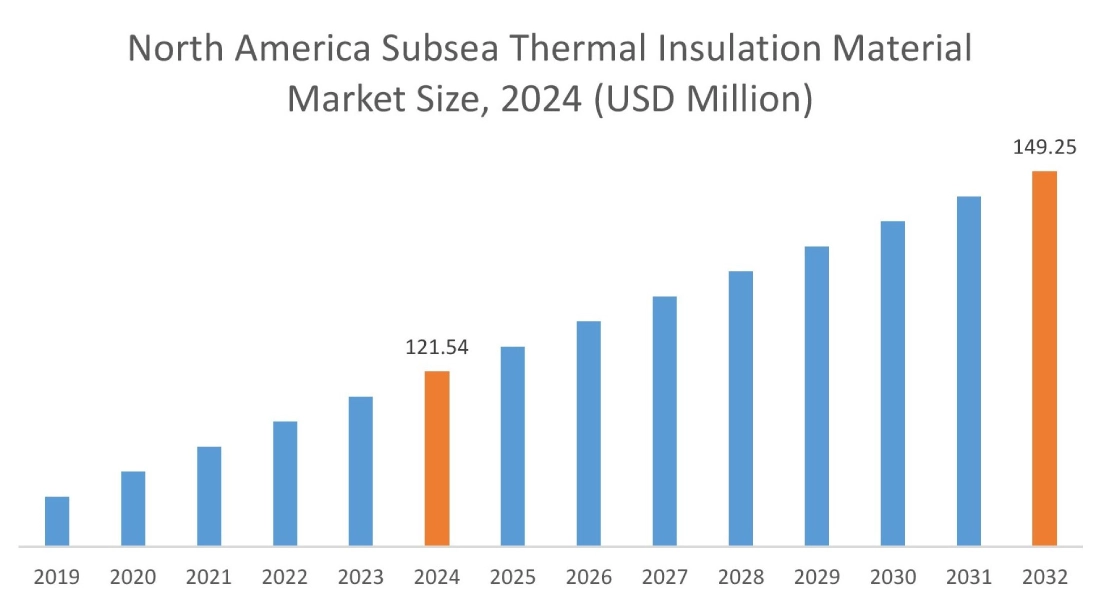

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

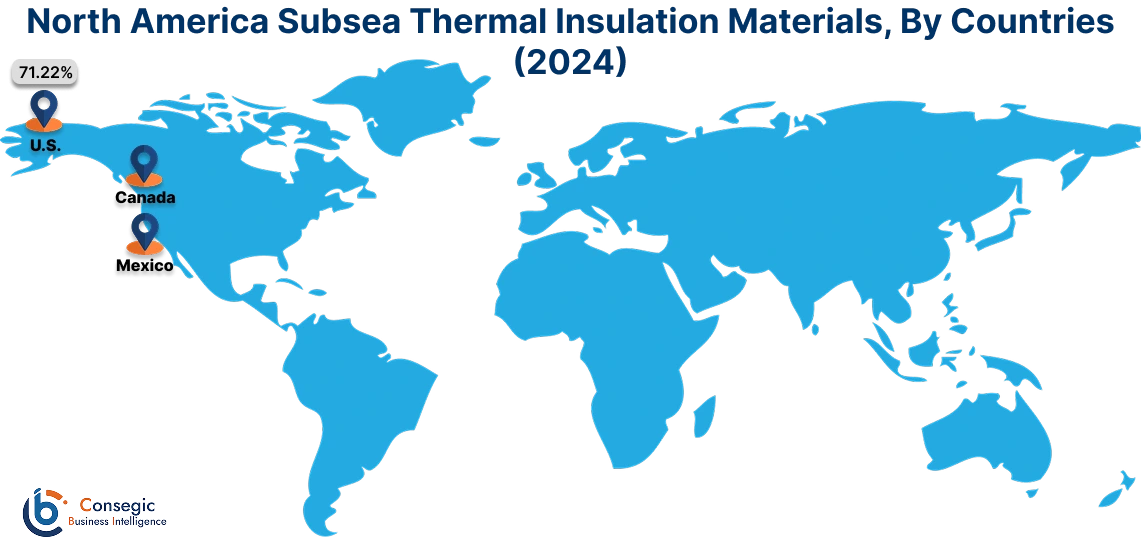

In 2024, North America accounted for the highest market share at 40.17% and was valued at USD 121.54 million and is expected to reach USD 149.25 million in 2032. In North America, U.S. accounted for the market share of 71.22% during the base year of 2024.

North America is important for global oil and gas production, mainly because of its diverse energy landscape that includes significant onshore shale plays and substantial offshore reserves. The challenging subsea environments, because of the extreme pressures, low temperatures, and long tie-back distances to processing facilities, necessitate highly specialized engineering solutions to ensure the reliable and efficient flow of hydrocarbons. The rise in the production of oil and gas is influencing the use of subsea thermal insulation material.

For instance,

- The data published in EIA, states that oil production rose from 12.2 million barrels per day in December 2022 to 13.3 million barrels per day in December 2023.

Thus, based on the market analysis, these factors create a strong upward trajectory for the market in North America, positioning it as a key region for players.

In Europe, the Subsea Thermal Insulation Material industry is experiencing the fastest growth with a CAGR of 3.2% over the forecast period. Polyurethane (PU) stands as an important material in the demanding field of subsea thermal insulation, particularly prevalent in Europe's extensive offshore energy sector. Its superior properties make it an ideal choice for protecting critical infrastructure such as pipelines, risers, and various subsea equipment from the extreme conditions found at great depths. Additionally, the growth of polyurethane in several applications, where this compound enhances durability is attributing to market development. These factors contribute to market trends in Europe.

The Asia Pacific (APAC) region is a global one of the major region for energy demand, which is characterized by a rapidly expanding industrial base, and growing urban centers. Within this dynamic energy landscape, both energy storage solutions and Subsea Thermal Insulation Materials play a complementary role in ensuring energy security, efficiency, and sustainability. These factors align with Asia Pacific’s region focus for more sustainable and cost-effective energy storage. These above-mentioned factors are contributing to the Subsea Thermal Insulation Material market trends in this region.

The Latin American region has significant offshore oil and gas exploration and production activities, especially in deepwater and ultra-deepwater fields. These deepwater environments present extreme challenges, including very low ambient temperatures that cause hydrate formation or wax deposition within pipelines, leading to blockages and stoppages. Polypropylene is a which is used as a due to its excellent chemical resistance, low density, good mechanical properties, and relatively low cost. Therefore, effective thermal insulation of subsea flowlines, risers, and equipment is critical to ensure uninterrupted flow and operational efficiency. Thus, as per the subsea thermal insulation material market analysis, the aforementioned factors are influencing the trend of the market.

In the Middle East, the subsea oil and gas sectors in the Middle East and Africa (MEA) is a critical component of global energy supply, which is influenced by increasingly challenging exploration and production environments. As operations extend into deeper waters and harsh conditions, enhanced engineering solutions are important to ensure efficient and uninterrupted flow assurance. Among these, pipe-in-pipe (PIP) systems and specialized Subsea Thermal Insulation Materials play a fundamental role, directly impacting project viability and operational safety across the region's vast offshore fields. Additionally, based on the Subsea Thermal Insulation Material market analysis the aforementioned factors are contributing to the Subsea Thermal Insulation Material market trends in this region.

Top Key Players and Market Share Insights:

The Global Subsea Thermal Insulation Material Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Subsea Thermal Insulation Material market. Key players in the Subsea Thermal Insulation Material industry include

- Aspen Aerogels, Inc (U.S.)

- AIS (Thailand)

- TechnipFMC plc (U.K)

- Huntsman International LLC (U.S.)

- Cabot Corporation (U.K)

- BASF SE (Germany)

- Trelleborg AB (Sweden)

- Dow (U.S.)

- Shawcor Ltd (Canada)

Subsea Thermal Insulation Material Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 386.43 Million |

| CAGR (2025-2032) | 3.2% |

| By Material Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Subsea Thermal Insulation Material market? +

In 2024, the Subsea Thermal Insulation Material market is USD 302.56 Million.

Which is the fastest-growing region in the Subsea Thermal Insulation Material market? +

Europe is the fastest-growing region in the Subsea Thermal Insulation Material market.

What specific segmentation details are covered in the Subsea Thermal Insulation Material market? +

By Material and Application segmentation details are covered in the Subsea Thermal Insulation Material market.

Who are the major players in the Subsea Thermal Insulation Material market? +

Aspen Aerogels, Inc (U.S.), AIS (Thailand), Cabot Corporation (U.K) are some of the major players in the market.