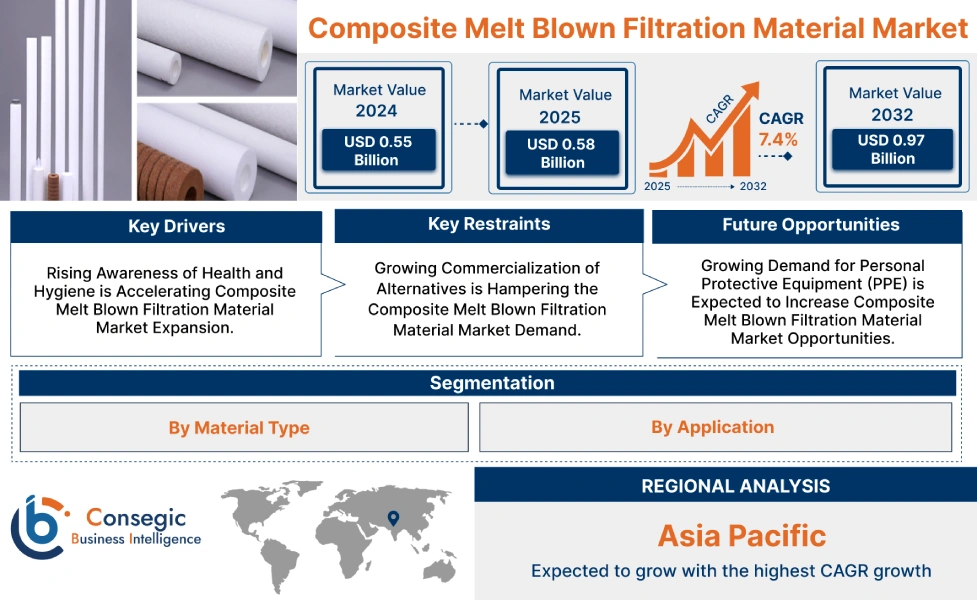

Composite Melt Blown Filtration Material Market Size:

Composite Melt blown Filtration Material Market size is growing with a CAGR of 7.4% during the forecast period (2025-2032), and the market is projected to be valued at USD 0.97 Billion by 2032 from USD 0.55 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 0.58 Billion.

Composite Melt Blown Filtration Material Market Scope & Overview:

Composite melt-blown filtration material is a nonwoven fabric engineered for filtration. It is produced by extruding molten polymer fibers through a high-speed air stream, creating a fine, self-bonding web. This web is combined with other layers to enhance strength and filtration efficiency. Common materials in production include polypropylene (PP), polybutylene terephthalate (PBT), and polyethylene terephthalate (PET) amongst others. The available net weights typically range from 85-90 g/m², 90-100 g/m², and above 100 g/m². Key applications include personal protective equipment (masks, gowns, and others), air filtration (HVAC, air purifiers, and others), liquid Filtration (water filters, oil filters, and others), hygiene products (wipes, pads, and others), and various other specialized uses.

How is AI Transforming the Composite Melt Blown Filtration Material Market?

AI is being increasingly used in the composite melt-blown filtration material sector, specifically for optimizing manufacturing processes, enhancing product performance, and streamlining quality control. Moreover, AI-powered solutions can analyze production data to identify inefficiencies and predict potential defects, which leads to reduced waste, improved consistency, and higher production efficiency.

Additionally, AI-driven systems can predict equipment failures, which enables proactive maintenance and minimizes downtime, in turn maximizing production efficiency. Hence, the above factors are expected to drive the market during the forecast period.

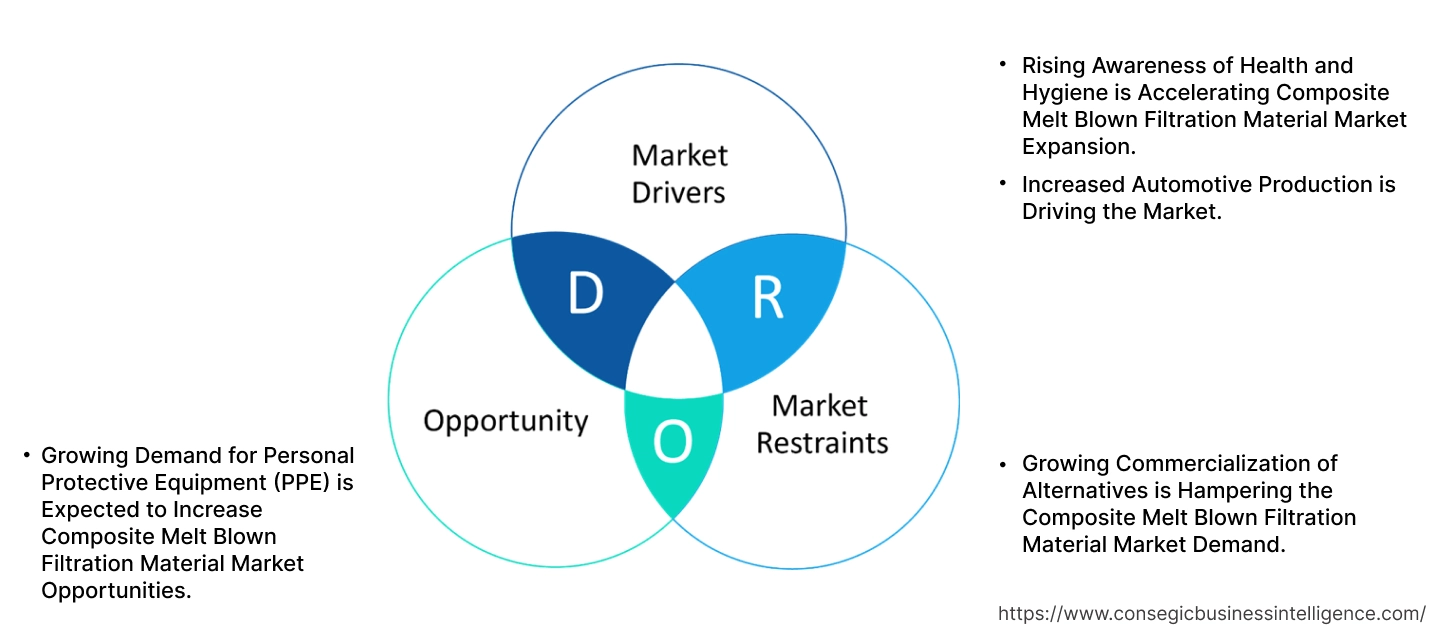

Key Drivers:

Rising Awareness of Health and Hygiene is Accelerating Composite Melt Blown Filtration Material Market Expansion.

The rising public consciousness surrounding health and hygiene, particularly concerning air and waterborne illnesses, has significantly amplified the need for household purification devices. Consumers are actively seeking air purifiers to combat indoor pollutants and water purifiers to ensure potable water. Consequently, manufacturers are responding by introducing innovative and advanced purification products to cater to this rising need, thus directly increasing the demand for these filtration materials.

For instance,

- According to a Blueair survey in 2023, revealed that a significant majority of Americans (96%) recognize the impact of indoor air quality on their physical and mental well-being. Furthermore, American parents prioritized air purifiers above all other products, thus positively influencing the composite melt blown filtration material market trends.

Overall, the rising awareness of health and hygiene is significantly boosting the composite melt blown filtration material market expansion.

Increased Automotive Production is Driving the Market.

Composite melt blown filtration material is crucial in automotive HVAC applications, primarily in cabin air filters to enhance air quality inside vehicles by capturing dust, pollen, and pollutants. They are also used in engine air intake filters and fuel filters for efficient particle removal. Increase in electric vehicles sales and government initiatives promoting manufacturing and exports have led to increased production of cars, impacting the need for these filtration materials.

For instance,

- According to the German Association of the Automotive Industry, passenger car production in Germany reached 4.1 million units in 2023, representing an 18% increase compared to the previous year, thus positively influencing the composite melt blown filtration material market trends.

Thus, the increased automotive production is accelerating the global composite melt blown filtration material market growth.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Composite Melt Blown Filtration Material Market Demand.

The market faces competition from other substitutes available in the market. Pleated filters are made from cellulose, synthetic fibers, or a blend, and offer a larger surface area within a compact space, leading to higher dirt-holding capacity and longer lifespan in applications such as HVAC and air purifiers. They are more cost-effective for coarser particulate filtration. Moreover, membrane filters utilize thin, semi-permeable barriers. They excel in achieving very high levels of purity in liquid and gas streams. Additionally, electrostatic filters use an electrostatic charge to attract and trap airborne particles. They boast lower pressure drop and are effective against fine particles such as smoke and some allergens. Hence, the growing commercialization of alternatives is hampering the composite melt blown filtration material market demand.

Future Opportunities :

Growing Demand for Personal Protective Equipment (PPE) is Expected to Increase Composite Melt Blown Filtration Material Market Opportunities.

Composite melt blown filtration material is a critical component in various types of PPE, most notably in respiratory protection such as face masks (including surgical, N95, and FFP types), reusable respirators, and protective clothing. Its fine fiber structure provides efficient filtration of airborne particles, including dust, viruses, and bacteria, while maintaining breathability. Stricter workplace safety regulations across various industries are requiring more PPE supplies, creating increased need for the market.

For instance,

- According to a study published by the National Center for Biotechnology Information, the South Korea PPE supplies market is expected to increase to a 20% CAGR by 2025.

Overall, growing requirements for personal protective equipment are expected to increase composite melt blown filtration material market opportunities.

Composite Melt Blown Filtration Material Market Segmental Analysis :

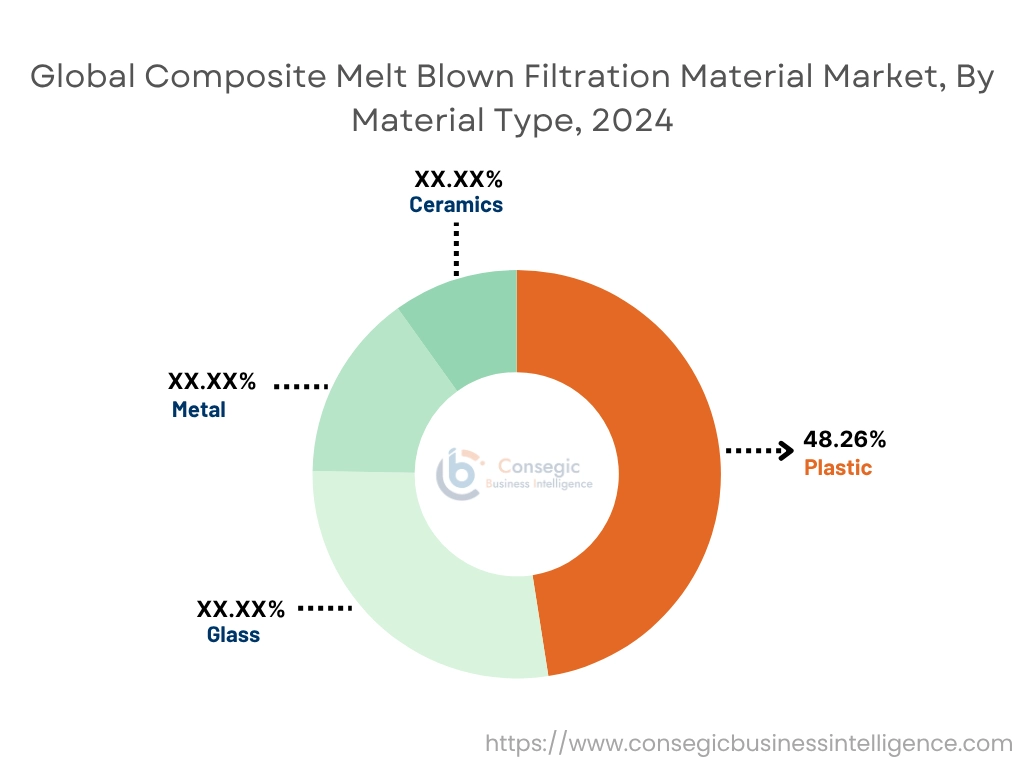

By Material Type:

Based on material type, the market is categorized into polypropylene (PP), polybutylene terephthalate (PBT), polyethylene terephthalate (PET), and others.

Trends in Material Type:

- PBT usage is in trend for applications requiring higher temperature resistance and specific chemical compatibility, particularly in automotive and industrial filtration.

- Driven by environmental concerns, there is an increasing trend towards using recycled PET (rPET) in melt blown filtration, along with research into bio-based PET alternatives to reduce reliance on virgin polymers.

The polypropylene (PP) segment accounted for the largest market share of 48.26% in 2024.

- Polypropylene (PP) is dominant in the market as it provides good chemical resistance to a wide range of substances, low moisture absorption, and inherent hydrophobicity. This makes it suitable for various air filtration applications.

- Additionally, an increase in understanding of the health risks associated with contaminated water has led to a significant surge in the need for water purifiers where in melt blown filtration material made from polypropylene material are utilized.

- For instance, according to Aquasana, the percentage of Americans using water purifiers grew from 73% in 2020 to 77% in 2023.

- Thus, as per the market analysis, the increased water purifier manufacturing is driving a segment in composite melt blown filtration material market growth.

The polybutylene terephthalate (PBT) segment is expected to grow at the fastest CAGR over the forecast period.

- Polybutylene terephthalate offers distinct advantages in melt-blown filtration, particularly due to its superior resistance to high temperatures and various chemicals, including fuels and organic solvents. This makes it ideal for automotive applications such as fuel filters, lubricant filters, and crankcase ventilation filters.

- PBT's dimensional stability and low moisture absorption further enhance its performance in these environments.

- The increasing need for high-performance filtration in automotive and industrial sectors where exposure to harsh conditions is common is driving the segment.

- Henceforth, as per the composite melt blown filtration material market analysis, the rising need for filtration solutions capable of withstanding harsh conditions will drive the segment for the upcoming years.

By Application :

Based on application, the market is categorized into personal protective equipment (PPE), air filters, liquid filters, hygiene products, and others.

Trends in the Application

- With rising concerns about in-cabin air quality and increasing vehicle production (especially EVs), there is a shift towards higher-efficiency melt-blown filters that capture finer particulate matter, allergens, and even odors.

- There is a growing trend towards incorporating bio-based or biodegradable melt-blown materials in hygiene products such as wipes and absorbent cores to address environmental concerns.

The air filters segment accounted for the largest market share in 2024.

- Composite melt blown filtration material is crucial in air filters due to their fine fibers, offering a high surface area for efficient particle capture.

- These nonwoven fabrics, made of polypropylene, are electrostatically charged to enhance filtration efficiency, capturing dust, pollen, and even smaller particles such as PM2.5.

- They are vital in vacuum cleaners, car air conditioners, and HVAC systems amongst others.

- Increased manufacturing of these products is positively influencing the need for these filtration materials.

- For instance, According to Utility Dive, Carrier Global Corp. experienced an 11% organic growth in its HVAC sales.

- Overall, as per the market analysis, growing filtration systems manufacturing is the driving segment in the composite melt blown filtration material industry.

The personal protective equipment (PPE) segment is expected to grow at the fastest CAGR over the forecast period.

- The composite melt blown filtration material is integral to the production of essential PPE items such as respiratory masks (surgical, N95, FFP), protective gowns, and head coverings.

- The fine fiber structure of melt-blown nonwovens provides crucial filtration efficiency against airborne particles, including dust, bacteria, and viruses, while maintaining breathability for user comfort.

- The requirements within this segment have seen significant growth, particularly due to increased health awareness and stringent safety regulations in healthcare, industrial, and public sectors.

- Ongoing innovations focus on improving the filtration performance, comfort, and sustainability of these materials for the evolving PPE landscape.

- Thus, as per the market analysis, stricter safety mandates across various industries will drive segmental growth in the composite melt blown filtration material industry for the forecasted years.

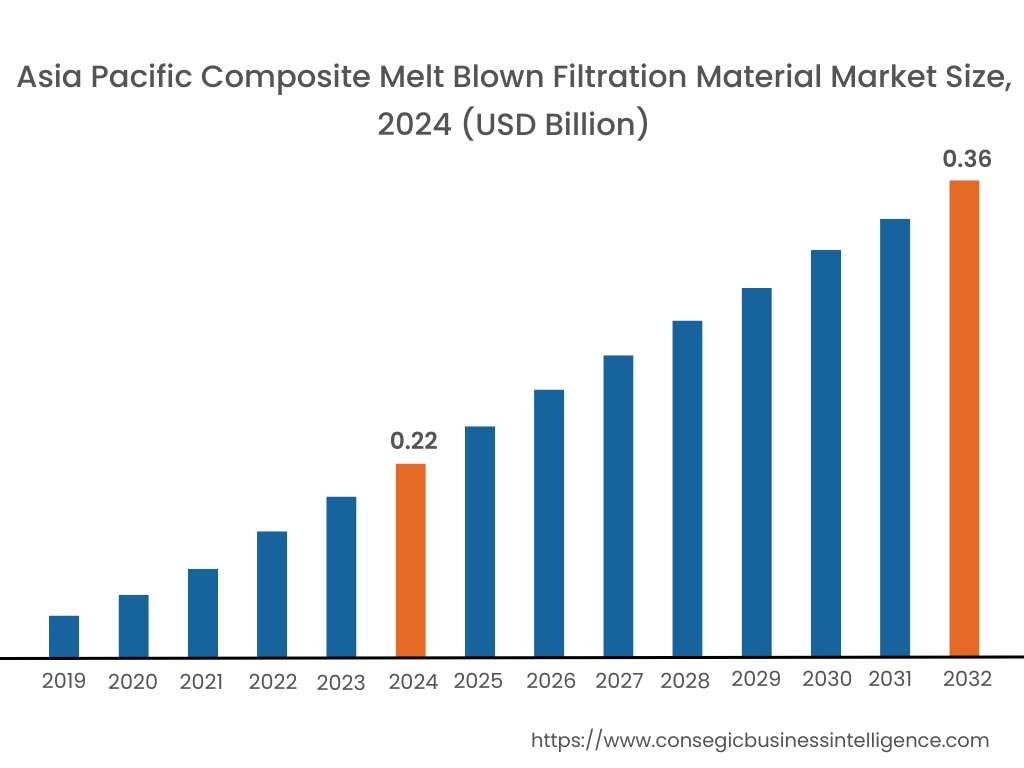

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest composite melt blown filtration material market share at 40.12% and was valued at USD 0.22 Billion and is expected to reach USD 0.36 Billion in 2032. In Asia Pacific, the China accounted for the composite melt blown filtration material market share of 36.55% during the base year of 2024. There is an increase in escalating rates of respiratory ailments and allergic reactions across the Asia-Pacific region, which are significantly propelling the demand for high-efficiency air purifiers incorporating composite melt-blown materials.

For instance,

- According to a study published by BMC Public Health, China experienced a surge in the prevalence of 7 respiratory diseases at the end of 2021 when compared to 2020.

Moreover, growing water scarcity and concerns about waterborne contaminants are driving the demand for efficient water filtration technologies, where melt blown materials play a role in pre-filtration and specialized filtration stages. Thus, the rising production of air filters and water filters is driving a market in the region.

In Europe, the composite melt blown filtration material market is experiencing the fastest growth with a CAGR of 9.2% over the forecast period. The expanding automotive industry is a significant sector, and the increasing focus on cabin air quality is a key driver for the market. Consumers are increasingly aware of the health implications of poor in-car air, demanding better filtration to reduce allergens, pollutants, and odors. This heightened awareness, coupled with rising vehicle production in certain countries within Europe, fuels the need for efficient cabin air filters. Composite melt blown filter materials offer the necessary filtration efficiency and breathability for these applications, making them a preferred choice for automotive manufacturers aiming to enhance passenger comfort and well-being.

The North America composite melt blown filtration material market analysis indicates that several key trends are contributing to its growth in the region. Continuous technological advancements in filtration media are a significant driver for the market in the region. Innovations such as nanofiber integration enhance the surface area and filtration efficiency, allowing for the capture of smaller particles with lower pressure drop, crucial for energy-efficient systems. Electrostatic charging (electret treatment) of melt-blown layers significantly improves their ability to trap submicron particles, vital in air purification and PPE. Furthermore, the development of specialized polymers tailored for the melt-blown process expands application possibilities.

The Middle East and Africa (MEA) region is experiencing a significant surge in the need for high-performance personal protective equipment (PPE). This is driven by a growing emphasis on worker safety across industries such as oil & gas, construction, and manufacturing, often characterized by hazardous working environments. Moreover, analysis indicates that increasing health awareness and stricter enforcement of safety regulations by governments and organizations are mandating the use of effective PPE, including respirators and masks that rely on composite melt-blown fabrics for their critical filtration layers.

Latin America presents a lucrative opportunity for the market. The escalating requirements for hygiene products across the region are a notable driver for the market. This growth is propelled by increased awareness of personal hygiene practices, rising disposable incomes allowing for greater spending on hygiene essentials, and expanding access to these products through growing retail infrastructure. Composite melt blown filtration material is integral to various hygiene applications, including diapers, sanitary napkins, and adult incontinence products, where they function as absorbent cores and fluid distribution layers. The need for these end-use products directly translates to higher consumption of composite melt-blown nonwovens.

Top Key Players and Market Share Insights:

The Composite Melt Blown Filtration Material market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Composite Melt Blown Filtration Material market. Key players in The Composite Melt Blown Filtration Material industry include-

- Hollingsworth & Vose (United States)

- Gessner (Germany)

- Filtrafine Corporation (Taiwan)

- Hongtek Filtration Co., Ltd. (China)

- Lydall, Inc. (United States)

- Handanhy (China)

- KINGFA Sci & Tech Co., Ltd. (China)

- Flowtech Corporation (United States)

- Mogul Textile (Turkey)

- Mingguan Purification Materials Co., Ltd. (China)

Composite Melt Blown Filtration Material Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 0.97 Billion |

| CAGR (2025-2032) | 7.4% |

| By Material Type |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Composite Melt Blown Filtration Material market? +

In 2024, the Composite Melt Blown Filtration Material market is USD 0.55 Billion.

Which is the fastest-growing region in the Composite Melt Blown Filtration Material market? +

Europe is the fastest-growing region in the Composite Melt Blown Filtration Material market.

What specific segmentation details are covered in the Composite Melt Blown Filtration Material market? +

Material Type and Application segmentation details are covered in the Composite Melt Blown Filtration Material market

Who are the major players in the Composite Melt Blown Filtration Material market? +

Hollingsworth & Vose (United States), Gessner (Germany), Handanhy (China), KINGFA Sci & Tech Co., Ltd. (China), Flowtech Corporation (United States), and Mogul Textile (Turkey) are some major players in the market.