Tow Prepreg Market Size:

The Tow Prepreg Market size is growing with a CAGR of 9.2% during the forecast period (2025-2032), and the market is projected to be valued at USD 6.35 Billion by 2032 from USD 3.16 Billion in 2024. Additionally, the market value for 2025 is attributed to USD 3.44 Billion.

Tow Prepreg Market Scope & Overview:

Tow prepreg is an advanced composite material intermediate. It consists of continuous fiber tows that have been precisely pre-impregnated with a thermoset or thermoplastic resin. This pre-impregnation process ensures a highly controlled fiber-to-resin ratio and uniform resin distribution, significantly enhancing the quality and consistency of the resulting composite part compared to traditional wet layup methods. The dry nature of tow prepregs facilitates cleaner handling and is particularly well-suited for automated manufacturing techniques such as filament winding and automated fiber placement, enabling high-speed production of complex, high-performance composite structures. Its inherent advantages in terms of material efficiency reduced voids, and superior mechanical properties position tow prepreg as a crucial material for sectors demanding lightweight, strong, and durable components.

How is AI impacting the Tow Prepreg Market?

AI-driven automation, including AFP and ATL, streamlines the manufacturing process of tow prepregs, leading to increased production speed, reduced labor costs, and enhanced precision. Also, AI-powered systems have the ability to monitor equipment performance and predict potential maintenance needs, minimizing downtime and maximizing production efficiency. AI-powered simulations can accurately predict the behavior of tow prepregs under various conditions, enabling engineers to optimize designs for specific applications and reduce the need for extensive physical testing.

Tow Prepreg Market Dynamics - (DRO) :

Key Drivers:

Growing Adoption in Aerospace and Defense Sector to Drive Tow Prepreg Market Growth.

Tow prepregs are distinguished by an exceptional strength-to-weight ratio and superior fatigue resistance. Such properties make them suitable for critical structural components such as wings, fuselages, and engine parts. The increasing global defense budgets, coupled with the rising production rates for next-generation and unmanned aerial vehicles, directly fuel the demand for these advanced composite materials.

- For instance, in 2023, Toray Industries supplied its Torayca carbon fiber and prepreg to the Japan Aerospace Exploration Agency (JAXA) for the H3 launch vehicle, with the carbon fiber used in the motor case and newly adopted prepreg in the payload fairing section.

Thus, as per the analysis, the growing market for composite material in the aerospace and defense sector is fueling significant tow prepreg market growth.

Key Restraints:

Competition from Alternative Materials to Hinder Tow Prepreg Market Expansion.

The wide range of alternatives poses significant competition to tow prepreg market demands, impeding market revenue. Traditional metallic alloys such as aluminum and steel remain a cost-effective and well-understood alternative for many structural components. Moreover, other composite material forms, such as dry fiber fabrics used in resin infusion processes and chopped fiber molding compounds offer lower material costs and simpler processing for specific applications. This ready availability and growing commercialization of substitutes creates a competitive landscape and supports players to adopt alternatives. As a result, the above-mentioned factors are limiting the tow prepreg market expansion.

Future Opportunities :

Adoption in Electric Vehicle Components to Create Tow Prepreg Market Opportunities.

The unique demands of electric vehicle (EV) powertrains are creating entirely new avenues for advanced composite materials. Tow prepregs are increasingly vital for lightweight EV components to offset the considerable weight of battery packs, thereby extending vehicle range and improving overall energy efficiency. This includes applications in battery enclosures and housings, where their high strength-to-weight ratio, impact resistance, and potential for integrated thermal management are critical for safety and performance. Furthermore, these materials are finding use in EV structural components, and chassis parts, among others where their ability to enable complex geometries offers both performance benefits and production efficiencies. This burgeoning EV ecosystem is poised to drive substantial demand for innovative prepreg solutions.

- For instance, new IEA report indicates that global electric car sales are projected to constitute over a quarter of worldwide car sales, and are on track to surpass a 40% market share by 2030.

Henceforth, the increasing adoption of EVs is creating lucrative tow prepreg market opportunities over the forecast period.

Tow Prepreg Market Segmental Analysis :

By Fiber Type:

Based on Fiber Type, the market is categorized into carbon fiber, glass fiber, aramid fiber, and others.

Trends in Fiber Type:

- Continuous innovation in high-strength and high-modulus carbon fibers is a growing trend.

- The trend of automated manufacturing processes such as AFP and filament winding that leverage the benefits of tow prepregs is rising.

The carbon fiber segment accounted for the largest tow prepreg market share in 2024 and is also expected to grow at the fastest CAGR over the forecast period.

- Carbon fiber tow prepregs are highly valued for their exceptional strength-to-weight ratio, high stiffness, excellent fatigue resistance, and thermal stability.

- They are produced as untwisted bundles of continuous carbon filaments, which are then precisely impregnated with resin.

- The growing focus on lightweighting in high-performance applications such as aerospace, high-end automotive, wind energy, and pressure vessels drives the segment revenue.

- The increasing use of composite pressure vessels for hydrogen storage is a strong factor for the segment.

- For instance, in 2023, Voith Composites achieved on-road certification under UNECE R 134 regulations for its towpreg-wound, 700-bar, 350-liter Carbon4Tank, making it ready for application in heavy-duty trucks and other commercial vehicles in Europe.

- Thus, as per the tow prepreg market analysis, the carbon fiber segment is dominating the tow prepreg market demand and is expected to grow over the forecast period.

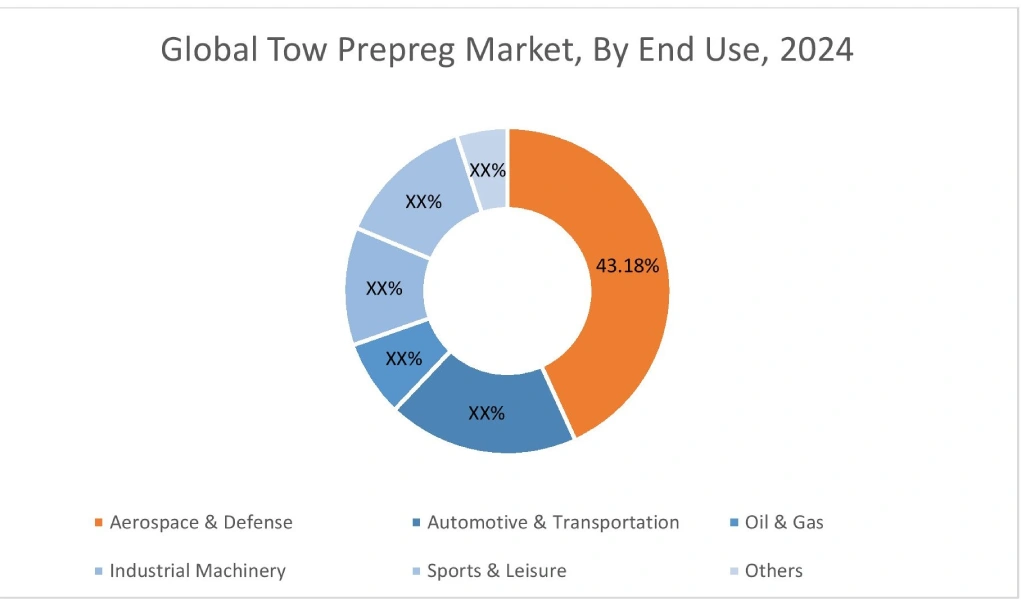

By End Use:

Based on end use, the market is categorized into aerospace & defense, automotive & transportation, oil & gas, industrial machinery, sports & leisure, and others.

Trends in the End Use:

- There's a growing trend towards using tow prepregs in larger, more critical primary structures of commercial and military aircraft for enhanced fuel efficiency and performance.

- The rapid adoption of EVs is driving a strong trend for tow prepregs in battery enclosures, chassis components, and other structural parts to offset battery weight and maximize range.

The aerospace & defense segment accounted for the largest tow prepreg market share of 43.18% in 2024.

- This segment is the largest consumer of tow prepregs as it is critical for achieving lightweight, high-strength, and durable components in commercial and military aircraft, satellites, missiles, and UAVs.

- This includes primary and secondary structures, fuselage sections, wings, empennage, control surfaces, and interior components.

- The continuous emphasis on fuel efficiency, increased payload capacity, enhanced performance, and stringent safety regulations across the sector support the segment's growth.

- Growing defense budgets and the development of next-generation aircraft and unmanned systems also contribute significantly.

- For instance, New Zealand's 2025 Budget allocated USD 2.4 billion to defense spending, including USD 1.61 billion in capital and USD 336.72 million in operating funding for priority projects outlined in its Defense Capability Plan.

- Thus, as per the aforementioned factors, the aerospace & defense segment is dominating market growth.

The automotive & transportation segment is expected to grow at the fastest CAGR over the forecast period.

- The automotive & transportation segment includes the use of tow prepregs in passenger cars, light commercial vehicles, and heavy commercial vehicles.

- The focus is on lightweighting for improved fuel economy, reduced emissions, and enhanced safety.

- Global regulations on CO2 emissions and fuel efficiency coupled with the rapid growth of electric vehicles necessitating weight offset for battery packs, and the demand for high-performance sports cars serve as prominent factors for the segment revenue in upcoming years.

- Thus, based on the market analysis, automotive & transportation is the fastest-growing segment.

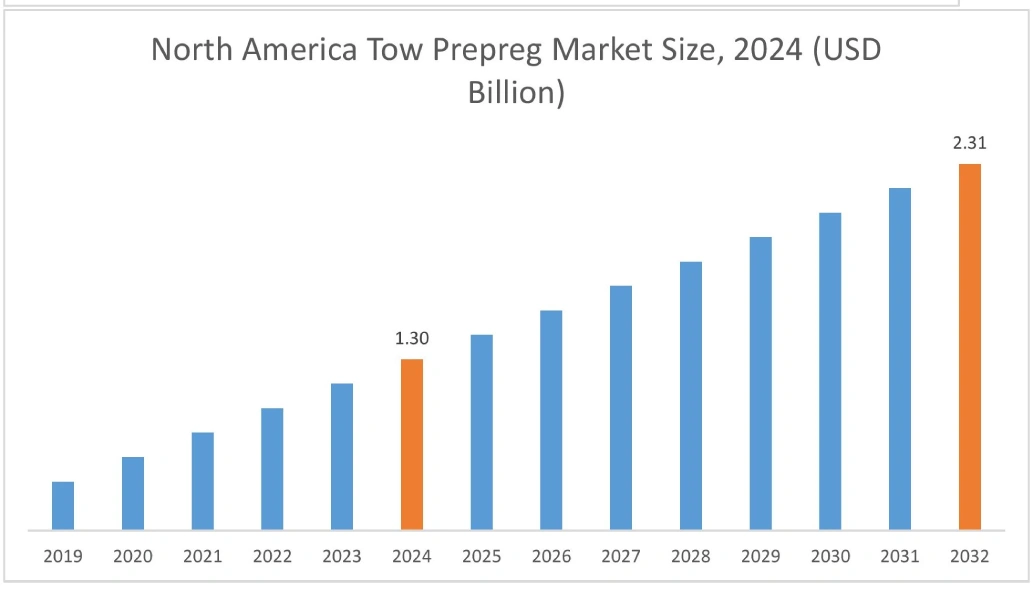

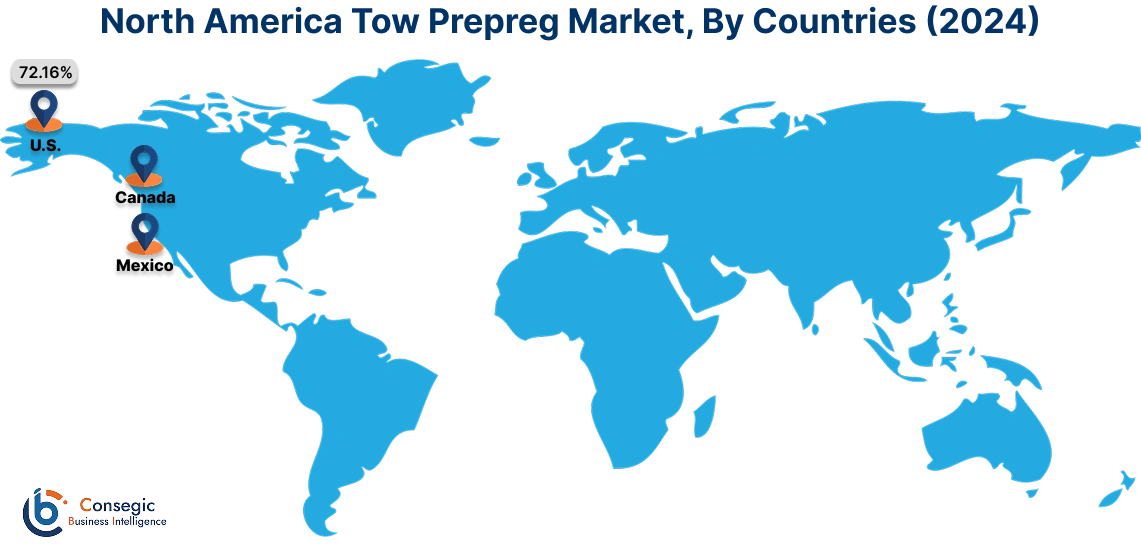

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest market share at 41.22% and was valued at USD 1.30 Billion and is expected to reach USD 2.31 Billion in 2032. In North America, the U.S. accounted for a market share of 72.16% during the base year of 2024. The upward trajectory of regional share is primarily driven by increasing aerospace and defense expenditure and rising demand for high-pressure composite vessels. The U.S. continually invests heavily in advanced aircraft, military systems, and space technologies. This sustained investment directly fuels the demand for high-performance, lightweight tow prepregs for critical structural and non-structural components.

- For instance, according to the Aerospace Industries Association, the U.S. aerospace and defense sector achieved sales exceeding USD 955 billion in 2023, representing a 7.1% increase from the preceding year.

Concurrently, the region also presents an established hydrogen economy. The demand for advanced Type IV and Type V pressure vessels creates significant market revenue. Thus, as per analysis, these factors collectively position North America as a key region for the market.

In Asia Pacific, the tow prepreg industry is experiencing the fastest growth with a CAGR of 12.2% over the forecast period owing to growing demand for lightweight materials across its diverse automotive, aerospace, and wind energy sectors, coupled with rapid technological advancements in composite manufacturing. Countries like China and India are witnessing a rise in their automotive sectors, driven by rising consumer demand and a strong shift towards electric vehicles, where lightweighting is crucial for extended range and performance. Simultaneously, the aerospace sector in the region is expanding rapidly, with increasing investments in both commercial and defense aircraft manufacturing, leading to a higher uptake of tow prepregs for critical structural components. Collectively these factors fuel Asia Pacific tow prepreg market analysis.

The European market is significantly propelled by its position in technological advancements in composite manufacturing and the growth in the wind energy sector. Europe boasts a highly sophisticated manufacturing ecosystem, with extensive investment in automated processes to optimize the use of tow prepregs, enabling faster production cycles and greater precision for complex composite structures. Concurrently, Europe is at the forefront of global efforts in renewable energy, with ambitious targets for wind power capacity. The continuous development of larger and more efficient wind turbine blades directly fuels market development across the continent. Hence, as per analysis, these factors collectively present a positive impact on the European tow prepreg market trends.

The market in Latin America is defined by the growing demand for lightweight materials within its expanding automotive and emerging wind energy sectors, alongside a rising demand for performance-driven sports and recreational goods. Countries in the region are witnessing significant automotive sector growth, with a rising focus on fuel efficiency and the gradual introduction of electric vehicles. Simultaneously, the region's abundant wind resources are attracting increasing investments in wind energy projects, particularly for large turbine blades where tow prepregs are crucial. Furthermore, there's an increased demand for high-end sporting equipment that leverages the superior strength-to-weight properties of advanced composites, further stimulating tow prepreg market trends across Latin America.

The market in the Middle East and Africa is characterized by increasing activities within the oil & gas sector. This region holds some of the world's largest and lowest-cost hydrocarbon resources, with substantial investments continuously being made in both upstream and downstream projects. Tow prepregs are increasingly vital for developing lightweight, corrosion-resistant, and high-pressure composite pipes, risers, and pressure vessels, which are crucial for efficient and safe operations in challenging environments like offshore drilling and gas processing. The ongoing focus on enhancing the efficiency, safety, and sustainability of oil and gas infrastructure in the region, coupled with major project pipelines, directly drives the demand for these advanced composite materials.

Top Key Players and Market Share Insights:

The Global Tow Prepreg Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Tow Prepreg market. Key players in the Tow Prepreg sindustry include

- Toray Industries, Inc. (Japan)

- Hexcel Corporation (U.S.)

- TCR Composites, Inc. (U.S.)

- Gurit Services AG (Switzerland)

- Huntsman Corporation (U.S.)

- Teijin Limited (Japan)

- SGL Carbon (Germany)

- Mitsubishi Chemical Corporation (Japan)

- Solvay (Belgium)

- ENEOS Techno Materials Corporation (Japan)

Tow Prepreg Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 6.35 Billion |

| CAGR (2025-2032) | 9.2% |

| By Fiber Type |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Tow Prepreg market? +

In 2024, the Tow Prepreg market is USD 3.16 Billion.

Which is the fastest-growing region in the Tow Prepreg market? +

Asia Pacific is the fastest-growing region in the Tow Prepreg market.

What specific segmentation details are covered in the Tow Prepreg market? +

By Fiber Type and End Use segmentation details are covered in the Tow Prepreg market.

Who are the major players in the Tow Prepreg market? +

Toray Industries, Inc. (Japan), Hexcel Corporation (U.S.), Teijin Limited (Japan), SGL Carbon (Germany), Mitsubishi Chemical Corporation (Japan) are some of the major players in the market.