Evaporation Materials Market Size:

Evaporation Materials Market size is growing with a CAGR of 6.7% during the forecast period (2025-2032), and the market is projected to be valued at USD 3.20 Billion by 2032 from USD 1.91 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 2.03 Billion.

Evaporation Materials Market Scope & Overview:

Evaporation materials are substances such as metals, alloys, and compounds (oxides, sulfides, nitrides, and others). These materials undergo rigorous purification processes. This is to achieve ultra-high purity levels such as 99.999%. They are then processed into specific forms such as pellets, rods, wires, and foil among others. These forms are optimized for stable melting in deposition systems. They are designed for forming thin films on substrates in a vacuum environment. The key properties of these materials include high purity, controlled vaporization characteristics, and low outgassing. Moreover, it is beneficial in providing specific electrical, optical, and protective qualities tailored to the desired thin film's function.

Evaporation Materials Market Dynamics - (DRO) :

Key Drivers:

Booming Semiconductor Industry is Accelerating the Evaporation Materials Market Expansion.

Evaporation materials are used to deposit thin films of metals and metal oxides onto silicon wafers. These films are crucial for building components such as integrated circuits and microprocessors. They are beneficial in preventing defects and also ensure devices have reliable performance. Some common materials used are aluminum, copper, titanium, and silicon dioxide (SiO2) among others are used. Increasing demand across various sectors such as AI and autonomous vehicles is driving semiconductor manufacturing, hence requiring these materials for multiple applications.

For instance,

- According to the United States International Trade Commission, Taiwan's semiconductor industry output between 2018 and 2022 grew at a CAGR of 17.04%, thus positively impacting evaporation materials market trends.

Overall, the booming semiconductor industry is significantly boosting the evaporation materials market expansion.

Increasing Manufacturing of Electric Vehicles is Driving the Market.

In the next-generation batteries of electric vehicles, evaporation materials such as lithium are deposited as ultra-thin layers of anodes and electrolytes. This enhances their energy density and safety. They also help by efficiently removing heat from batteries and other components of these vehicles. This ensures optimal performance and longevity. Aluminum is a common material used due to its low cost, and good thermal and electrical conductivity. Environmental concerns, economic benefits, and government support are leading to sector growth, thus requiring these materials for multiple applications.

For instance,

- According to the International Energy Agency, global electric car sales surged by 35% year-on-year in 2023, thus positively impacting the evaporation materials market trends.

Thus, increasing manufacturing of electric vehicles is accelerating the global evaporation materials market growth.

Key Restraints:

Stringent Purity Requirements and Contamination Risks are Hampering the Evaporation Materials Market Demand.

Even minute impurities in sensitive applications such as semiconductor manufacturing, display production, and advanced optical coatings lead to catastrophic defects in the deposited thin films. These defects compromise electrical performance and optical clarity. They also create disturbances in mechanical integrity. This results in device failure and substantial yield losses. Moreover, achieving and maintaining such ultra-high purity requires costly raw material sourcing. Additionally, sophisticated refining processes and highly controlled manufacturing environments are required. This includes cleanrooms and vacuum packaging among others. This complexity and the associated elevated costs for R&D are limiting its wider adoption. Hence, the stringent purity requirements and contamination risks are hampering the evaporation materials market demand.

Future Opportunities :

Expanding Medical Device is Expected to Increase Evaporation Materials Market Opportunities.

Evaporation materials are used to deposit ultra-thin films on a wide range of medical devices. Materials such as hydroxyapatite and titanium nitride are used in orthopedic implants, dental implants, and cardiovascular stents. They are evaporated to form biocompatibility and provide excellent corrosion resistance properties. Moreover, they are also beneficial in providing hardness, wear resistance, and lubricity to surgical instruments. Rising chronic disease and increasing healthcare spending have led to sector increase, hence creating the potential for these materials.

For instance,

- According to, Cyient, the European medical device sector is expected to grow at a CAGR of 5.8%. This creates potential for the market.

Overall, the expanding medical device is expected to increase the evaporation materials market opportunities.

Evaporation Materials Market Segmental Analysis :

By Material Type:

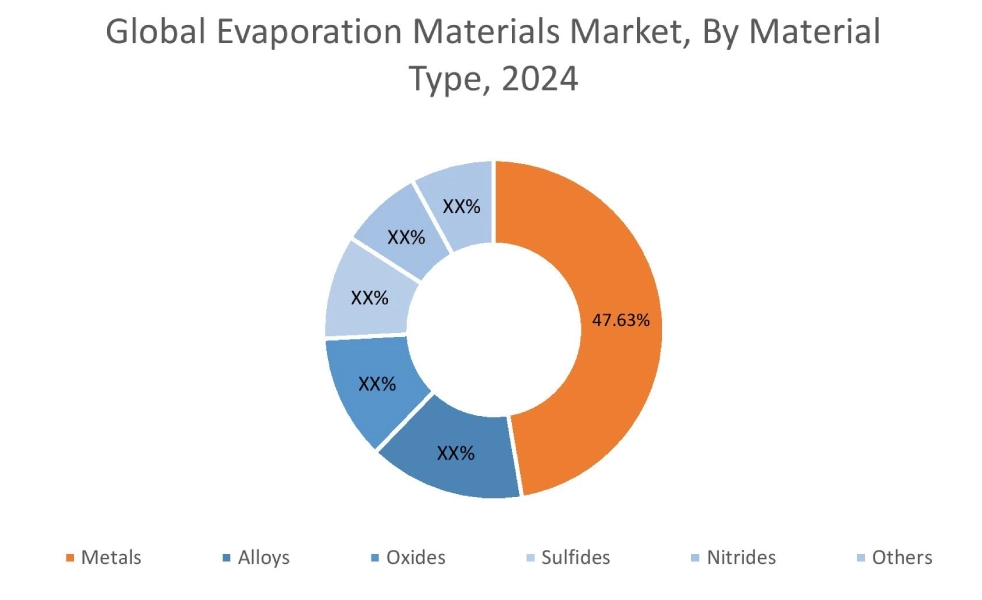

Based on material type, the market is categorized into metals, alloys, oxides, sulfides, nitrides, and others.

Trends in Material Type:

- Growing trend of using aluminum, copper, and titanium due to their cost-effectiveness and widespread availability.

- The usage of cadmium sulfide and zinc sulfide in thin-film solar cell technologies is also a rising trend.

The metals segment accounted for the largest market share of 47.63% in 2024.

- The metal segment of the market includes pure elements chosen for their specific physical and chemical properties when deposited as thin films.

- Common examples include aluminum (Al), copper (Cu), gold (Au), silver (Ag), chromium (Cr), and titanium among others. They offer excellent electrical conductivity. This makes them ideal for circuitry.

- They also provide high thermal conductivity, which makes them crucial for heat dissipation in electronic components.

- Additionally, many metals provide superior reflectivity for optical applications and are highly malleable. All these benefits are driving its increased usage.

- Overall, as per the market analysis, the aforementioned factors are driving a segment in the evaporation materials market growth.

The oxides segment is expected to grow at the fastest CAGR over the forecast period.

- Oxides include chemical compounds of elements with oxygen. They form dielectric and semiconducting thin films.

- Common examples include silicon dioxide (SiO2), titanium dioxide (TiO2), indium tin oxide (ITO), and aluminum oxide (Al2O3) among others.

- They are applied as biocompatible coatings on implants and surgical instruments. Moreover, they are essential in display production to create transparent conductive layers. Rapid production of these medical devices and displays will drive the segment.

- For instance, Samsung Display plans to increase its AMOLED panel production by 10% in 2025,focusing on high-value products such as tablets and foldable displays.

- According to the evaporation materials market analysis, the aforementioned factors will drive the segmental share for the upcoming years.

By Form:

Based on form, the market is categorized into pellets, rods, wires, foils, and others.

Trends in the Form

- Pellets are preferred due to their excellent flowability and ease of loading into electron beam guns.

- Wire forms remain crucial for resistive thermal evaporation. This is especially true for materials with lower melting points. The trend is towards longer, continuously fed wires for extended, uninterrupted deposition runs.

The pellets segment accounted for the largest market share in 2024.

- Pellets offer excellent consistency in ranges and mass. This is beneficial in gaining precise control over the amount of material being evaporated.

- Their uniform shape ensures stable feeding into evaporation sources. This leads to a more consistent and reliable deposition process.

- It also helps in achieving uniform heating and reduced spitting. This minimizes defects in the deposited film and improves overall product yield.

- They are also easy to handle and load into evaporation systems. All these benefits have contributed to their increased usage in automotive, optical, and medical device sectors.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the evaporation materials industry.

The wires segment is expected to grow at the fastest CAGR over the forecast period.

- Wire forms offer excellent continuous feeding capabilities. This allows for prolonged deposition runs.

- Its continuity ensures highly stable evaporation rates and consistent film thickness. This makes it useful in industries requiring high-volume coating processes such as packaging.

- There is rising consumer demand for convenient products. This has led manufacturers to increase their packaging production capacity, hence requiring these wires for multiple applications.

- For instance, in 2025, Oliver Healthcare Packaging opened a new manufacturing facility in Malaysia. This facility will produce pouches, lids, and roll stock for medical and pharmaceutical packaging.

- Thus, according to market analysis, the aforementioned factors are driving segmental growth for the forecasted years.

By End-Use:

Based on end-use, the market is categorized into electronics, automotive, aerospace & defense, medical device, consumer goods, and others.

Trends in the End-Use

- The aerospace and defense sector is increasingly using evaporation materials for lightweight, durable, and high-performance coatings on critical components. This is helping them in enhancing fuel efficiency and protection.

- There is a growing trend of using evaporation materials in consumer goods to impart functional properties such as scratch resistance.

The electronics segment accounted for the largest market share in 2024.

- In electronics, evaporation materials facilitate the creation of smaller, denser, and more powerful electronic components.

- They provide superior electrical conductivity, insulation, and optical properties. This leads to faster processing speeds and improved signal integrity.

- Moreover, ultra-high purity materials are advantageous in providing minimal defects, which is crucial for device reliability and lifespan. Rising global demand for electronics has led to sector increase, hence driving segment in the market.

- For instance, according to IBEF, India’s domestic electronics production grew at a CAGR of 13.53% from FY17 to FY23.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the market.

The medical device segment is expected to grow at the fastest CAGR over the forecast period.

- The medical device sector heavily relies on evaporation materials to enhance functionality.

- They protect devices from degradation in the harsh bodily environment. This extends their functional lifespan while ensuring long-term reliability. This is vital for implants and surgical instruments.

- Coatings on catheters and guide wires are helpful in enhancing patient comfort and ease of use during medical procedures.

- Moreover, they offer biocompatibility, which minimizes adverse reactions to the human body. This promotes integration and reduces rejection.

- Thus, according to market analysis, the aforementioned factors will drive segmental growth for the forecasted years.

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

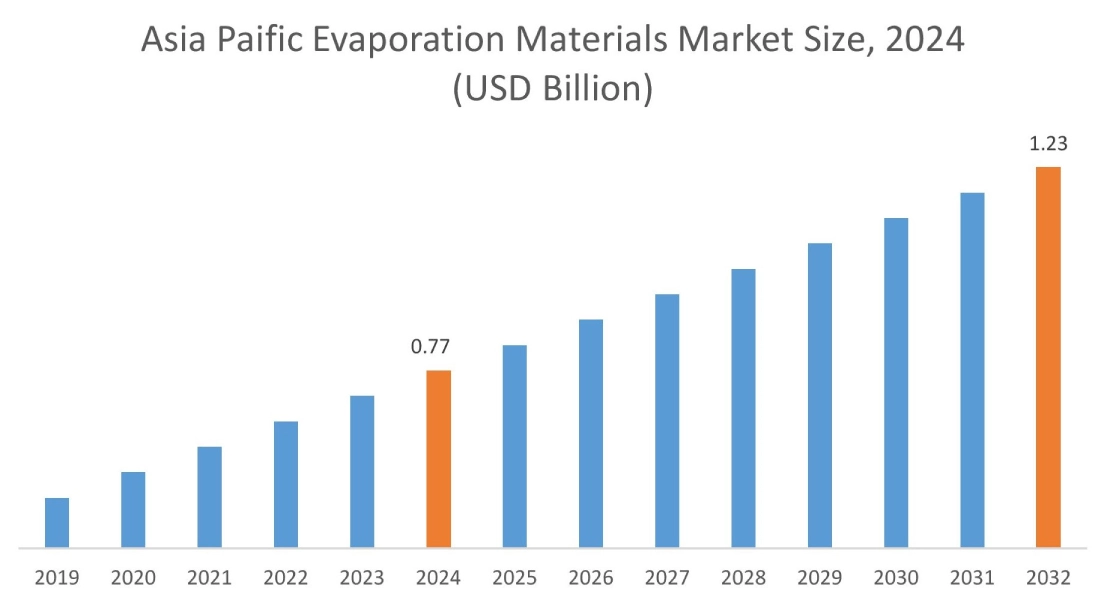

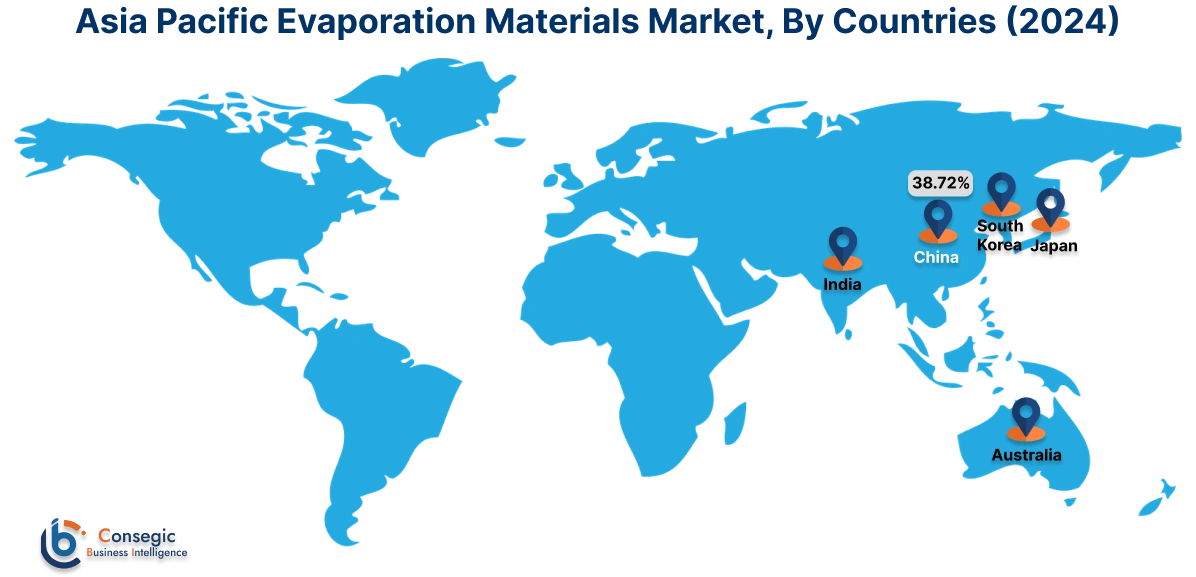

In 2024, Asia Pacific accounted for the highest evaporation materials market share at 40.62% and was valued at USD 0.77 Billion and is expected to reach USD 1.23 Billion in 2032. In Asia Pacific, the China accounted for the evaporation materials market share of 38.72% during the base year of 2024. There is expanding semiconductor production in the region. This is fueled by significant government investments and a strong manufacturing ecosystem. Countries such as Taiwan, South Korea, Japan, and China, dominate global chip manufacturing.

For instance,

- According to the Semiconductor Association, China's expanded wafer capacity represented 26% of the global increase.

This increased production directly influences the higher demand for evaporation materials. These materials are critical for depositing ultra-pure thin films. This includes metals for interconnectors and oxides for insulation among others. They provide excellent thermal management and superior electrical conductivity. Overall, growing semiconductor manufacturing is driving the market in the region.

In Europe, the evaporation materials market is experiencing the fastest growth with a CAGR of 8% over the forecast period. The region is strong focusing on the solar energy sector. This is driven by ambitious renewable energy targets such as the EU’s 42.5% renewable energy by 2030. This has led to substantial growth in solar PV installations. This surge directly boosts the demand for high-purity evaporation materials. These materials are crucial for manufacturing thin-film solar cells such as Cadmium Telluride and Copper Indium Gallium Selenide among others.

North America’s evaporation materials market analysis indicates that several key trends are contributing to its growth in the region. There is an increase in the automotive sector in the region. The region is experiencing substantial investments in EV production capabilities and a rising consumer inclination towards electric mobility and advanced safety features. Advanced battery technologies rely on evaporation materials for anode and electrolyte layers to enhance energy density and charging efficiency. They also protect these batteries from getting overheated. This eventually extends the lifespan of batteries.

Middle East and Africa (MEA) market analysis indicates that there is a significant rise in the production of optical components in the region. This is driven by substantial investments in telecommunications infrastructure and smart city initiatives. Evaporation materials are key for telecommunication networks, data centers, and 5G deployment, requiring precise coatings for signal integrity and durability. They are used as optical sensors in smart cities applications and industrial automation, where thin films enhance sensitivity and performance.

Latin America's region creates potential for the market. There is a growing aerospace and defense sector in the region. This is fueled by modernization efforts, rising defense budgets in countries such as Brazil, Colombia, and Chile due to regional security concerns, and a push for domestic manufacturing capabilities. Evaporation materials are applied as anti-corrosion coatings on engine parts, airframes, and landing gear. This improves lifespan and operational efficiency. They also provide wear-resistant properties with excellent thermal barrier protection.

Top Key Players and Market Share Insights:

The Evaporation Materials market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Evaporation Materials market. Key players in The Evaporation Materials industry include-

- Stanford Advanced Materials (United States)

- Angstrom Sciences, Inc. (United States)

- EVOCHEM Advanced Materials GmbH (Germany)

- Plasmaterials, Inc. (United States)

- ATT Advanced Elemental Materials Co., Ltd. (United States)

- Umicore N.V. (France)

- EdgeTech Industries LLC (United States)

- Nichia Corporation (Japan)

- Materion Corporation (United States)

- China Rare Metal Material Co., Ltd. (China)

Evaporation Materials Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3.20 Billion |

| CAGR (2025-2032) | 6.7% |

| By Material Type |

|

| By Form |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Evaporation Materials market? +

In 2024, the Evaporation Materials market is USD 1.91 Billion.

Which is the fastest-growing region in the Evaporation Materials market? +

Europe is the fastest-growing region in the Evaporation Materials market.

What specific segmentation details are covered in the Evaporation Materials market? +

Material Type, Form, and End-Use segmentation details are covered in the Evaporation Materials market.

Who are the major players in the Evaporation Materials market? +

Stanford Advanced Materials (United States), Umicore N.V. (France), EdgeTech Industries LLC (United States), Nichia Corporation (Japan), Materion Corporation (United States), and China Rare Metal Material Co., Ltd. (China) are some major players in the market.