Continuous Stirred Tank Reactors (CSTR) Market Size:

The Continuous Stirred Tank Reactors (CSTR) Market size is growing with a CAGR of 4.9% during the forecast period (2025-2032), and the market is projected to be valued at USD 5.05 Billion by 2032 from USD 3.46 Billion in 2024. Additionally, the market value for 2025 is attributed to USD 3.61 Billion.

Continuous Stirred Tank Reactors (CSTR) Market Scope & Overview:

Continuous Stirred Tank Reactors (CSTR) is a type of chemical reactor that is widely used in various industrial processes. They are mainly used for reactions where thorough mixing is important. The reactor mainly operates on the principle of continuous flow where the reactants are fed in the reactor and the product is removed continuously. CSTRs are widely utilized across various industrial sectors, including chemical, pharmaceutical, food & beverage, and water treatment, for processes that generally require control over reaction conditions and consistent product quality because of their excellent heat transfer capabilities and ease of operation.

Continuous Stirred Tank Reactors (CSTR) Market Dynamics - (DRO) :

Key Drivers:

The Growing Production of Specialty Chemicals is Driving the Continuous Stirred Tank Reactors (CSTR) Market Demand

Continuous Stirred Tank Reactor’s ability to provide accurate control over condition reaction and their suitability for manufacturing process continuously makes them an important component in the production of specialty chemicals, which is used by various end use markets. The rise in the production of specialty chemicals is influencing the use of this reactor.

For instance,

- The data in American Chemistry Council, Inc, states that more than 85% of basic and specialty chemicals are used by the industrial sector. Overall industrial production rose by 0.3% in 2023.

Thus, the rise in the production of specialty chemicals is influencing the Continuous Stirred Tank Reactors (CSTR) market demand.

Advancements in CSTR is Propelling the Continuous Stirred Tank Reactors (CSTR) Market Expansion.

Advancements in CSTR generally include the integration of technologies such as automation, IoT sensors, and advanced data analytics. These technologies generally provide properties such as real time monitoring, optimization of energy, and predictive maintenance. Additionally, manufacturers are introducing advanced reactors for integration with flow chemistry systems mainly for proper handling of solid materials and access long reaction time.

For instance,

- In May 2023, Vaportech company introduced a unique continuous stirred tank reactor (CSTR) for integration with Vapourtec’s flow chemistry systems. These reactors enhance the ability to handle solids, separation of liquids and gases, access long reaction times and provide active mixing.

Thus, advancements in these reactors are encouraging the growth of the market.

Key Restraints:

Commercialization of Alternative Reactors is Hampering the Continuous Stirred Tank Reactors (CSTR) Market Growth.

Various alternative reactors are employed in chemical processes, each offering numerous advantages depending on the reaction kinetics, desired conversion, heat transfer requirements, and operational flexibility. Some of the reactors include batch reactors, plug flow reactors, semi-batch reactors, and others. The batch reactors are flexible, which makes them ideal for small-scale production, research & development, and processes with frequent changes. The plug-flow reactor provides high conversion rates mainly for reactions where the rate is proportional to the concentration of reactants. The semi-batch reactors mainly provide better control over reaction rates, improve selectivity by maintaining low concentrations of a reactant, and are useful for two-phase reactions. Thus, the availability of these reactors ultimately hinders the market.

Future Opportunities :

The Increasing Investments in Water Treatment Infrastructure Create Continuous Stirred Tank Reactors (CSTR) Market Opportunities.

As various countries focus on the development and modernization of drinking facilities, and wastewater management systems, there is a rise in the demand for effective solutions mainly for high-strength industrial wastewater. Continuous stirred tank reactors help in the breakdown of organic matter in sludge and wastewater. Additionally, it is ideal for processing high strength industrial wastewater. The rise in the water treatment infrastructure funding in enhancing the use of this reactor.

For instance,

- In September 2024, the S. Environmental Protection Agency announced the availability of USD 7.5 billion of Water Infrastructure Finance and Innovation Act (WIFIA) funding. The main aim is to protect waterways and implement cleaning practices.

Thus, due to the aforementioned factors, increasing focus on investment for water to create continuous stirred tank reactors (CSTR) market opportunities.

Continuous Stirred Tank Reactors (CSTR) Market Segmental Analysis :

By Material Type:

Based on Material Type, the market is categorized into glass lined steel, stainless steel, carbon steel, and others

Trend in Material Type

- The rising emphasis on the purity of the product and contamination prevention is influencing the trend for stainless steel material.

- The growing chemical synthesis of aggressive compounds drives the trends for glass lined steel material.

The stainless-steel segment accounted for the largest Continuous Stirred Tank Reactors (CSTR) market share in 2024.

- Stainless steel material holds the highest market share mainly because of its properties that include high durability and resistance to corrosion.

- It is primarily composed of iron and chromium which generally forms an oxidative layer that protects the metal from rust and the attack of chemicals.

- In CSTR applications, stainless steel is used mainly because of its strength, hygiene, and the ease of cleaning.

- This makes them ideal for various industries such as pharmaceutical, food & beverages, and water treatment where control of contamination is important.

- The rise in the pharmaceutical sector is influencing the use of reactors made from stainless steel.

- For instance, the data by India Brand Equity Foundation, states that, the Indian pharmaceutical sector is currently ranked 3rd in pharmaceutical production by volume growing at a CAGR of 9.43%.

- Thus, as per the market analysis, the growing use of stainless steel is influencing the segment growth.

The glass lined steel segment is expected to grow at the fastest CAGR over the forecast period.

- Glass-lined steel is a composite material used in continuous stirred tank reactors, mainly because of its superior performance where both strength and chemical inertness are critical.

- It consists of a steel shell which generally provides robust structural integrity and allows for high operating pressures and temperatures.

- The material is coated internally with a layer of special technical glass fused at high temperatures.

- This glass lining offers exceptional corrosion resistance to a wide range of acids and bases, preventing metal contamination of the product.

- Its smooth, non-porous surface also ensures product purity, provides easy cleaning, and minimizes cross-contamination.

- Thus, as per the market analysis the growing potential for glass lined steel is influencing the expansion of the segment in the coming years.

By End Use:

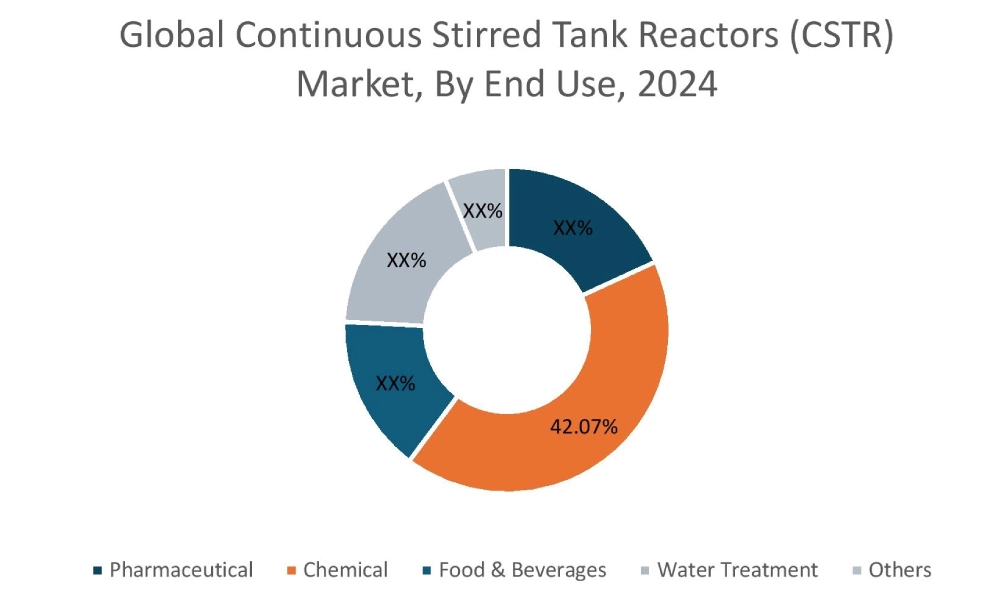

The End Use segment is categorized into pharmaceutical, chemical, food & beverages, water treatment, and others.

Trends in the End Use

- The growing need for consistent and efficient production of chemicals is influencing the use of continuous stirred tank reactors.

- The trend for developed water treatment infrastructure and use of novel reactors is influencing the use of this compound.

The chemical segment accounted for the largest Continuous Stirred Tank Reactors (CSTR) market share of 42.07% in 2024.

- CSTRs are important for the production of various chemical compounds, ranging from bulk chemicals to specialty chemicals and petrochemicals.

- The adoption of these reactors in the chemical sector is driven by their ability to provide continuous operation, which is important for high-volume manufacturing.

- CSTRs ensure uniform mixing and consistent reaction conditions throughout the reactor, which leads to highly predictable and reproducible product quality.

- The rise in the chemical sector is influencing the use of CSTR.

- For instance, the data by International Trade Administration states that Korea's chemical industry contributes a significant 14.3% to the nation's overall manufacturing output and accounting for 17% of its exports.

- Thus, as per the market analysis, the rise in the chemical sector is influencing the growth of the segment.

The water treatment segment is expected to grow at the fastest CAGR over the forecast period.

- In the treatment of water, Continuous Stirred Tank Reactors (CSTR) is an important solution that is widely used in the aerobic digester mainly to break down the organic matter into wastewater sludge in the absence of oxygen.

- They are also used in various chemical reactions that are involved in the purification of water such as disinfection, coagulation, and flocculation.

- As a result, based on the Continuous Stirred Tank Reactors (CSTR) market analysis, owing to the aforementioned factors, the water treatment segment is expected to have lucrative trends over the forecast period.

Regional Analysis:

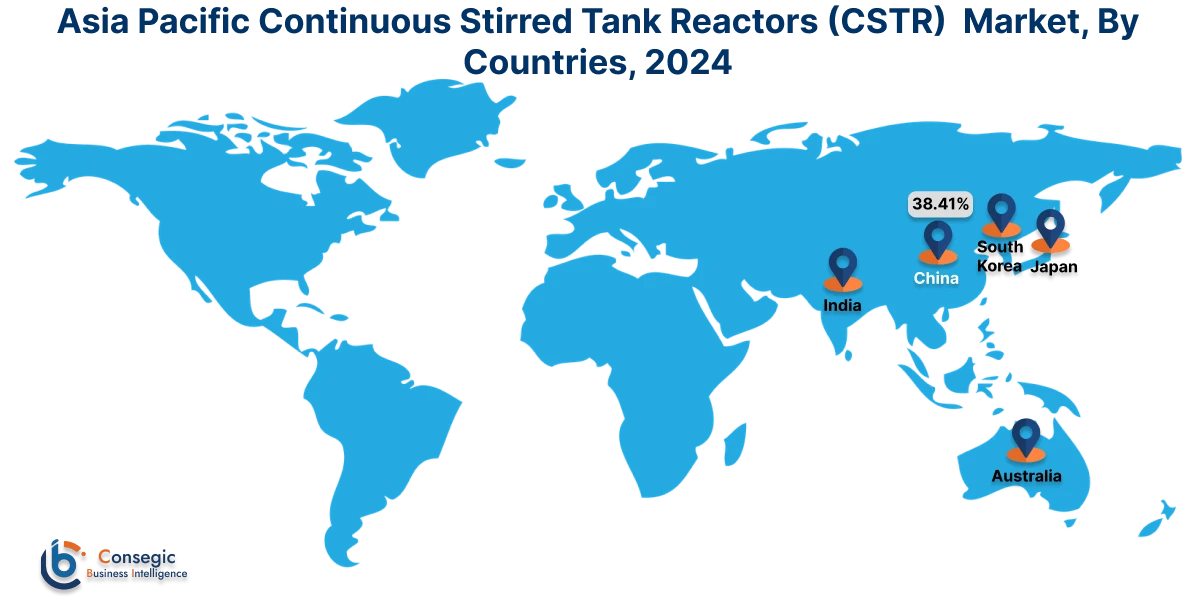

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

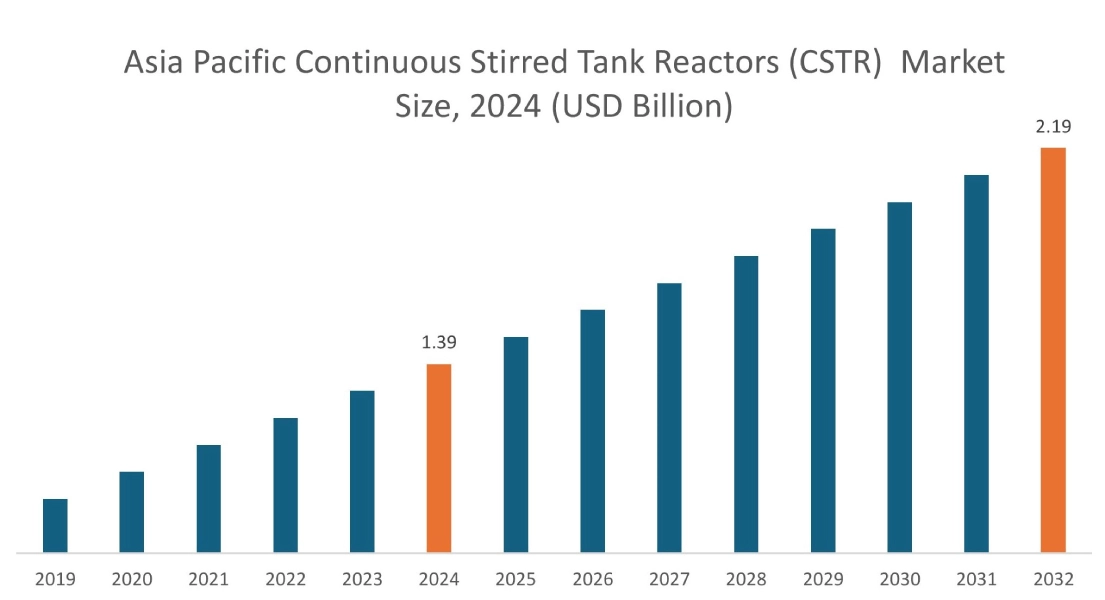

In 2024, Asia Pacific accounted for the highest market share at 40.11% and was valued at USD 1.39 Billion and is expected to reach USD 2.19 Billion in 2032. In Asia Pacific, China accounted for the market share of 38.41% during the base year of 2024. The Asia Pacific region is dominating, driven by the factors such as rapid industrialization, enhanced manufacturing capabilities, and significant investments in both bulk chemicals and specialty chemicals production, particularly in countries like China, India, and South Korea. CSTRs are important in these industries mainly because of the ability to provide continuous, high-volume production with consistent product quality and accurate control over reaction. This is essential for the development of various chemicals. The rise in the production of chemicals is influencing the use of CSTR.

For instance,

- The data by India Brand Equity Foundation states that, major chemical production reached 1,008.9 thousand metric tons in December 2024, while petrochemical production reached 1,840.22 thousand metric tons.

Thus, based on the Continuous Stirred Tank Reactors (CSTR) market analysis, the rise in the chemical sector is influencing the market growth in this region.

In Europe, the Continuous Stirred Tank Reactors (CSTR) industry is experiencing the fastest growth with a CAGR of 3.7% over the forecast period. In Europe, this reactor is being utilized in the water treatment sector due to the regions focus on strict environmental regulations as well as the aim of maintaining high quality water for both industrial and municipal uses. The compound is important for the aerobic digester mainly to break down the organic matter into wastewater sludge. The ongoing urbanization across Europe creates lucrative opportunities for this compound in wastewater, leading to the region’s market growth. Furthermore, as per the market analysis, Europe's focus on sustainable solutions makes this reactor a suitable option for water reuse in the region, thus influencing the continuous stirred tank reactors (CSTR) market growth in this region.

The advancements in continuous stirred tank reactors are aligning with the region’s demand for smart manufacturing. Manufacturers are increasingly focusing on integrating CSTR with various advanced solutions that include AI, IoT sensors, and flow chemistry systems. Additionally, there is growing use of reactors made from advanced materials that include glass lined steel. Thus, based on the market analysis, the growing adoption of advanced reactors is having a positive impact on the continuous stirred tank reactors (CSTR) market trends.

The Latin American market for Continuous Stirred Tank Reactors (CSTR) is expected to witness significant trends primarily because of the expanding pharmaceutical industry. The increasing focus on healthcare access, and local drug manufacturing is driving the demand for various pharmaceuticals. The growing need for enhanced production efficiency, consistent product quality, and reduced lead times is influencing the investment in advanced manufacturing technologies such as CSTRs. Thus, as per the market analysis, the growing need for continuous pharmaceutical manufacturing is influencing the use of this reactor, thus driving the continuous stirred tank reactors (CSTR) market expansion in this region.

In the Middle East and Africa region, CSTRs are crucial in the production of food and beverages for processes that require precise mixing, temperature control, and consistent quality, such as fermentation, enzymatic reactions, emulsification, pasteurization, and sterilization. The growing investment in food processing, in countries across the MEA, directly fuels the demand for these reactors, contributing to the continuous stirred tank reactors (CSTR) market trends in this region.

Top Key Players and Market Share Insights:

The Global Continuous Stirred Tank Reactors (CSTR) Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Continuous Stirred Tank Reactors (CSTR) market. Key players in the Continuous Stirred Tank Reactors (CSTR) industry include

- Vapourtec Ltd. (U.K)

- Amar Equipment Pvt Ltd (India)

- Shijiazhuang Zhengzhong Technology Co.,Ltd (China)

- Senyee Co., Limited (China)

- Pilon Engineering Pvt Ltd (India)

- UD Technologies (India)

- Armfield Limited (U.K)

- Erich Stallkamp ESTA GmbH (Germany)

- Edibon (Spain)

- Nano-Mag (India)

Continuous Stirred Tank Reactors (CSTR) Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 5.05 Billion |

| CAGR (2025-2032) | 4.9% |

| By Material Type |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Continuous Stirred Tank Reactors (CSTR) market? +

In 2024, the Continuous Stirred Tank Reactors (CSTR) market is USD 3.46 Billion.

Which is the fastest-growing region in the Continuous Stirred Tank Reactors (CSTR) market? +

Europe is the fastest-growing region in the Continuous Stirred Tank Reactors (CSTR) market.

What specific segmentation details are covered in the Continuous Stirred Tank Reactors (CSTR) market? +

By Material Type, and End Use segmentation details are covered in the Continuous Stirred Tank Reactors (CSTR) market.

Who are the major players in the Continuous Stirred Tank Reactors (CSTR) market? +

Vapourtec Ltd. (U.K), UD Technologies (India), Armfield Limited (U.K) are some of the major players in the market.