Cobalt Based Amorphous Alloy Market Size:

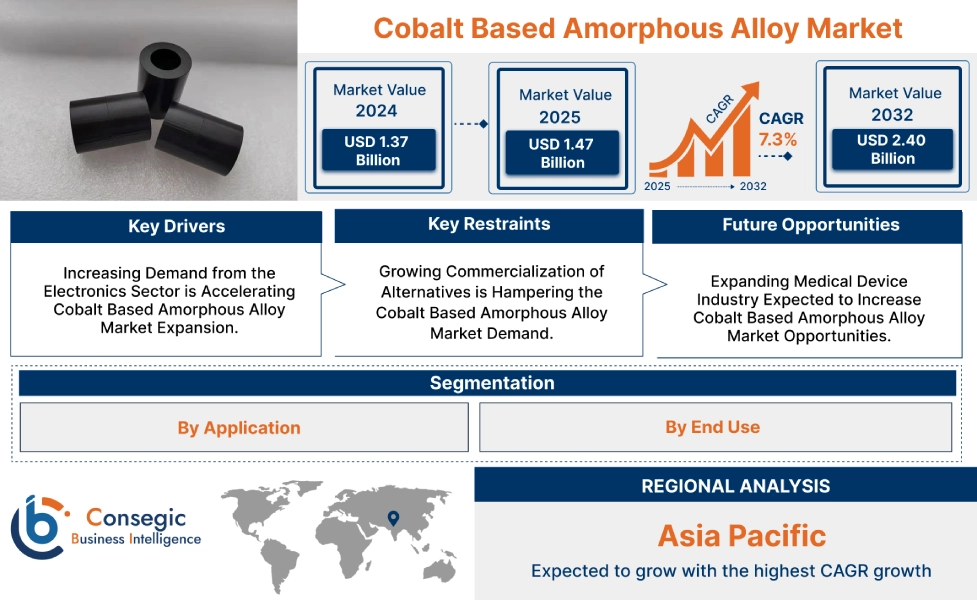

Cobalt Based Amorphous Alloy Market size is growing with a CAGR of 7.3% during the forecast period (2025-2032), and the market is projected to be valued at USD 2.40 Billion by 2032 from USD 1.37 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 1.47 Billion.

Cobalt Based Amorphous Alloy Market Scope & Overview:

A cobalt based amorphous alloy is a metal alloy where the atoms are arranged randomly rather than in a crystalline pattern and cobalt is a key component. This non-crystalline structure is achieved through rapid cooling processes. This leads to unique magnetic properties such as high permeability and low coercivity. It is known for its high magnetic permeability and low coercivity. This allows them to be easily magnetized and demagnetized, making them suitable for various magnetic applications. Moreover, they have high electrical resistivity. This reduces eddy current losses, making them suitable for high-frequency applications.

How is AI Impacting the Cobalt Based Amorphous Alloy Market?

Artificial Intelligence is significantly impacting the cobalt-based amorphous alloy market by enhancing material design, production efficiency, and performance optimization. Through advanced machine learning algorithms, researchers can predict alloy behavior, magnetic properties, and corrosion resistance under varying conditions, reducing reliance on traditional trial-and-error methods. AI-driven simulations accelerate the discovery of new alloy compositions with improved strength and thermal stability. In manufacturing, AI optimizes process parameters such as cooling rates and composition ratios, ensuring consistent product quality. Additionally, AI enhances supply chain management and demand forecasting for raw materials. Overall, AI integration is accelerating innovation, reducing costs, and improving the reliability of cobalt-based amorphous alloys in industrial and electronic applications.

Cobalt Based Amorphous Alloy Market Dynamics - (DRO) :

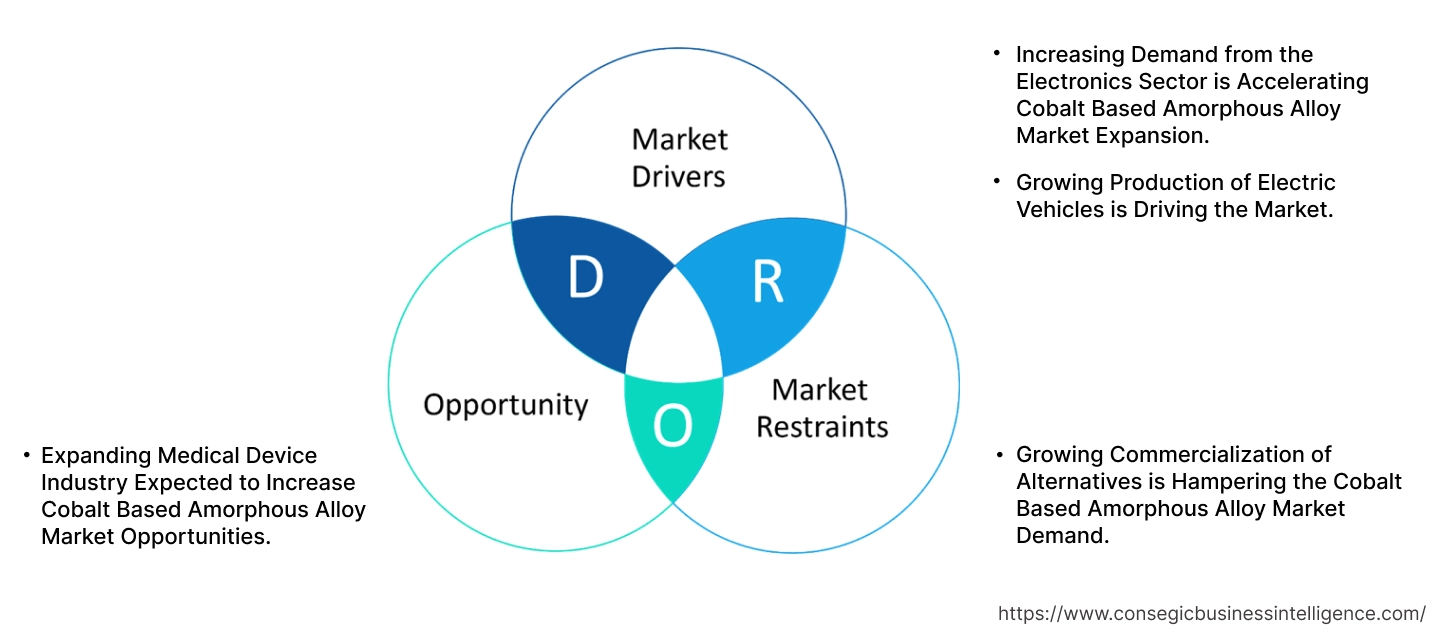

Key Drivers:

Increasing Demand from the Electronics Sector is Accelerating Cobalt Based Amorphous Alloy Market Expansion.

Cobalt based amorphous alloy is highly valued in the electronics sector due to their exceptional soft magnetic properties. They are used in power supplies, particularly in high frequency switching power converters. These alloys are also crucial for manufacturing inductors and chokes in various electronic circuits. Moreover, their excellent magnetic properties make them ideal for sensitive magnetic sensors in consumer electronics. The growing demand for smart devices and IoT technology has led to a sector increase, thus requiring these alloys for multiple applications.

For instance,

- According to the Singapore Business Review, Singapore's electronics output saw a 26.2% year-on-year increase in 2024, thus positively impacting cobalt based amorphous alloy market trends.

Overall, the increasing need from the electronics sector is significantly boosting the cobalt based amorphous alloy market expansion.

Growing Production of Electric Vehicles is Driving the Market.

Cobalt based amorphous alloy is increasingly utilized in EV motors, specifically within the stator and rotor cores. Their exceptionally low core losses at high frequencies minimize energy dissipation. It directly translates to extended driving range and reduced heat generation in the motor. This allows for more compact and lightweight motor designs, crucial for vehicle efficiency. They are also vital in on-board chargers and DC-DC converters within EVs. A combination of environmental concerns and government incentives has led to growth in the EV sector, driving the need for these alloys.

For instance,

- The International Energy Agency reported a significant 35% surge in global electric car sales during 2023, adding 3.5 million units more than in 2022, thus positively impacting the cobalt based amorphous alloy market trends.

Thus, the growing production of electric vehicles is accelerating the global cobalt based amorphous alloy market growth.

Key Restraints :

Growing Commercialization of Alternatives is Hampering the Cobalt Based Amorphous Alloy Market Demand.

The market faces competition from other substitutes available in the market. For instance, iron-based amorphous alloys offer good soft magnetic properties, high saturation induction, and excellent corrosion resistance for many power applications. Also, they offer lower production costs compared to cobalt-based variants. Moreover, nanocrystalline alloys such as FE-based alloys, which are formed by annealing amorphous precursors, boast excellent soft magnetic properties. Additionally, grain-oriented electrical steel is a crystalline material, that dominates low-frequency transformers and motors. This is due to its cost-effectiveness, wide availability, and well-established manufacturing processes. Hence, the growing commercialization of substitutes is hampering the cobalt based amorphous alloy market demand.

Future Opportunities :

Expanding Medical Device Industry Expected to Increase Cobalt Based Amorphous Alloy Market Opportunities.

Cobalt based amorphous alloy is used in long-term implants such as orthopedic prostheses. Their high strength, hardness, and excellent fatigue resistance ensure durability. Moreover, the unique magnetic properties and excellent corrosion resistance create potential for advanced biosensors and components in diagnostic equipment. Additionally, their high hardness and wear resistance make them ideal for creating durable and sharp surgical tools. Raising chronic disease prevalence and increasing healthcare spending has led to industry growth.

For instance,

- According to Masson International, the medical device market of Europe is expected to grow at a CAGR of 4.09% from 2022 to 2027. This creates the potential for the market.

Overall, the expanding medical device sector is expected to increase the cobalt based amorphous alloy market opportunities.

Cobalt Based Amorphous Alloy Market Segmental Analysis :

By Application:

Based on application, the market is categorized into magnetic sensors, vehicle components, transformers, diagnostic equipment, and others.

Trends in Application:

- The rising need for advanced electric grid solutions that enhance efficiency is influencing the use of transformers.

- The growing trend for efficient and fast diagnostic equipment is driving the use of advanced materials such as cobalt based amorphous alloy.

The transformers segment accounted for the largest market share in 2024.

- Cobalt based amorphous alloy is widely used in transformers mainly because of their exceptional soft magnetic properties. This enhances energy efficiency and performance.

- Transformers are essential components in electrical grids and electronic devices.

- These devices and electrical grids rely on core materials to efficiently transfer electrical energy.

- They are widely used in semiconductors mainly for power distribution, and voltage regulation. The rise in the adoption of semiconductors in various applications is influencing the use of these alloys.

- For instance, according to the Semiconductor Industry Association, semiconductor sales saw an increase of over 15% from 2023 to 2024.

- Overall, as per the market analysis, increasing semiconductor manufacturing is driving a segment in the cobalt based amorphous alloy market growth.

The diagnostic equipment segment is expected to grow at the fastest CAGR over the forecast period.

- Cobalt based amorphous alloy is finding increasing use in diagnostic equipment, particularly in applications such as magnetic field detection and sensors.

- Their unique properties, such as high magnetic permeability and low core loss, make them suitable for devices that require sensitive magnetic detection and high-frequency operation.

- Moreover, their inherent corrosion resistance and robust mechanical properties contribute to the long-term reliability and operational stability of diagnostic equipment in clinical environments. All these factors have contributed to its increased usage.

- According to market analysis, the aforementioned factors will drive the segment share for the upcoming years.

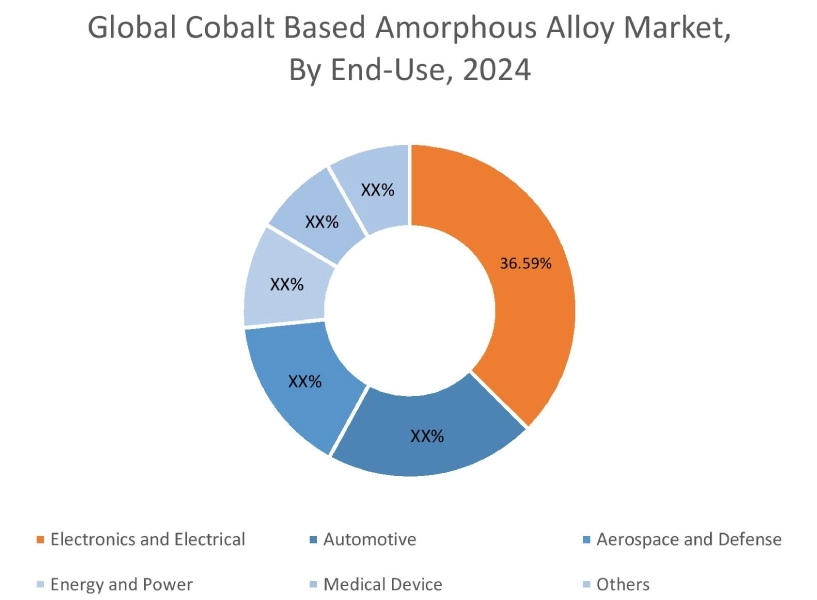

By End Use:

Based on end-use, the market is categorized into electronics & electrical, automotive, aerospace & defense, energy & power, medical device, and others

Trends in the End-Use

- There is a growing trend for high-performance electronics which is influencing the use of this material.

- The growing research and development in medical devices are propelling the use of this compound.

The electronics and electrical segment accounted for the largest market share of 36.59% in 2024.

- Cobalt based amorphous alloy is extensively utilized in the electronics and electrical sector, mainly as a critical material for enhancing the performance, efficiency, and miniaturization of various components.

- By minimizing the distribution of heat, these alloys allow the development of more energy-efficient devices.

- This aligns with global trends towards sustainable electronics and reduced power consumption.

- Additionally, the rise in the production of electronics is influencing the use of this alloy.

- For instance, according to Atradius N.V., the production of electronics is expected to grow by 8.2% in 2024 across the globe with a focus on meeting the increased need for advanced semiconductors.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the cobalt based amorphous alloy industry.

The medical device segment is expected to grow at the fastest CAGR over the forecast period.

- Cobalt based amorphous alloy is gaining momentum in the medical device sector due to their unique combination of properties that are highly advantageous for demanding environments.

- The smooth, uniform surface and resistance to ion release make them well-tolerated by the human body, minimizing inflammatory responses.

- Additionally, these alloys exhibit remarkable resistance to degradation, ensuring the longevity and integrity of implanted devices.

- Thus, according to cobalt based amorphous alloy market analysis, the aforementioned factors will drive the segment for the forecasted years.

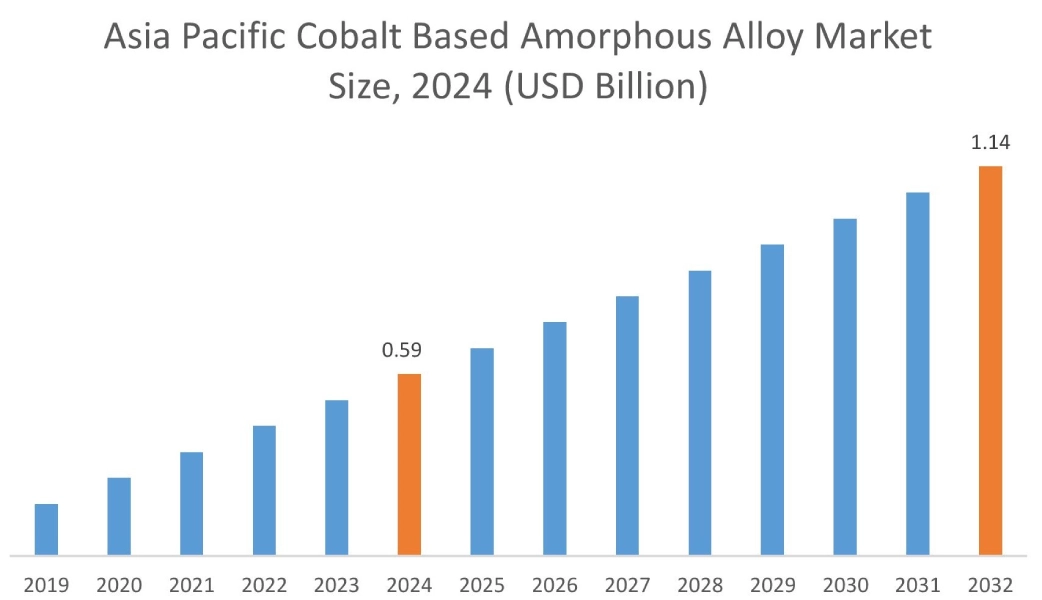

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

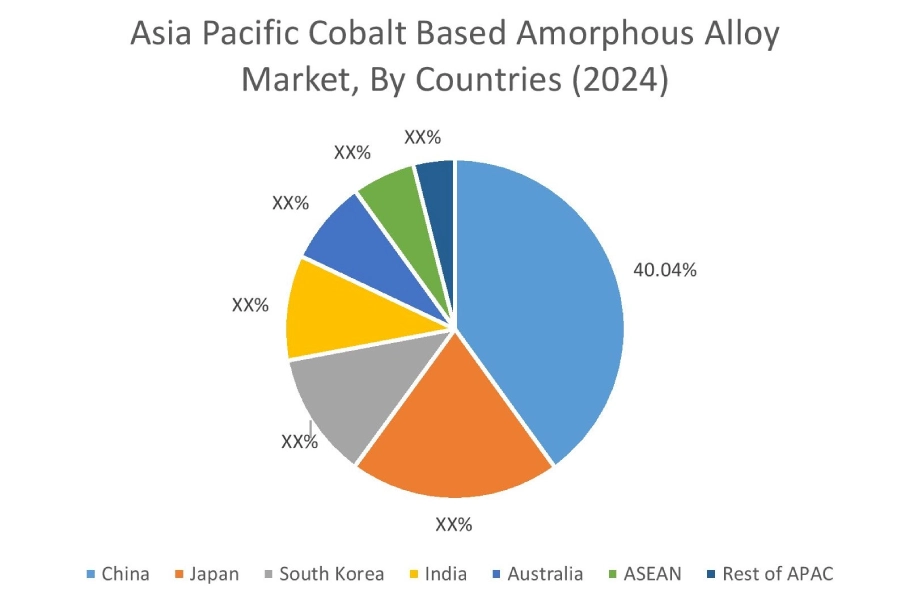

In 2024, Asia Pacific accounted for the highest cobalt based amorphous alloy market share at 43.11% and was valued at USD 0.59 Billion and is expected to reach USD 1.14 Billion in 2032. In Asia Pacific, the China accounted for the cobalt based amorphous alloy market share of 40.04% during the base year of 2024. The expanding automotive sector is a significant driver for the market. This growth is fueled by increasing disposable incomes, rapid urbanization, and substantial government support for the adoption of electric vehicles. Countries such as China, India, and South Korea lead the market.

For instance,

- According to Asian Automotive Analysis, motor vehicle production in South Korea increased by 8.5% in 2022 when compared to the previous year.

Cobalt based amorphous alloy is crucial in this transition. They are increasingly integrated into EV motors due to their exceptionally low core losses. This boosts energy efficiency and extends driving range. It is also beneficial in reducing heat generation. These alloys are also vital for on-board chargers, DC-DC converters, and inductors within vehicle components. They contribute to faster charging times. Overall, the growing automotive sector is driving the market in the region.

In Europe, the cobalt based amorphous alloy market is experiencing the fastest growth with a CAGR of 9.1% over the forecast period. Medical device production is increasing in the region. This is propelled by an aging population, rising prevalence of chronic diseases, and increasing healthcare expenditure. Countries such as Germany, France, and the UK lead the market. Cobalt based amorphous alloy is beneficial in providing exceptional biocompatibility and superior corrosion resistance. This makes them ideal for long-term implants such as orthopedic and dental prostheses. It also minimizes adverse reactions. Furthermore, their high strength, hardness, and wear resistance are crucial for crafting durable surgical instruments.

North America’s cobalt based amorphous alloy market analysis indicates that several key trends are contributing to its growth in the region. There is a rapid increase in electronics production, especially in the U.S. This is fueled by increasing investments in semiconductor manufacturing, the proliferation of 5G technology, and rising demand for consumer electronics. Cobalt based amorphous alloy provides ultra-low core losses and high magnetic permeability. This makes them ideal for high-frequency power supplies and transformers, enabling more compact and energy-efficient designs. They are also used in sensitive magnetic sensors for various electronic devices.

The Middle East and Africa (MEA) market analysis indicates that there is increasing awareness of advanced materials in the region. The understood benefits of cobalt based amorphous alloy is driving the increased usage. Moreover, there is substantial government investment in diversification and high-tech industries. Countries such as Saudi Arabia and the UAE are actively pursuing economic diversification away from oil, focusing on sectors such as advanced manufacturing, smart infrastructure, and renewable energy. This requires advanced transformers and inductors where cobalt based amorphous alloy excel due to their ultra-low core losses.

Latin America's region creates potential for the market. The Aerospace and defense sector is experiencing a notable increase in the region. This is fueled by ongoing military modernization programs, increasing geopolitical tensions, and a strategic focus on enhancing national security capabilities. Countries such as Brazil and Argentina lead the market. Cobalt based amorphous alloy provides a high strength-to-weight ratio and excellent corrosion resistance is crucial for lightweight aircraft components and durable parts in harsh environments. Furthermore, their unique magnetic properties make them valuable for high-frequency sensors and magnetic shielding in advanced avionics and defense systems.

Top Key Players & Market Share Insights:

The Cobalt Based Amorphous Alloy market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Cobalt Based Amorphous Alloy market. Key players in The Cobalt Based Amorphous Alloy industry include-

- Toshiba Materials Co., Ltd. (Japan)

- Metglas, Inc. (United States)

- Shouke (China)

- Stanford Advanced Materials (United States)

- Foshan Huaxin Microcrystalline Metal Co., Ltd. (China)

- Shenzhen Jufeng Solder Co., Ltd. (China)

- VACUUMSCHMELZE GmbH & Co. KG (Germany)

Cobalt Based Amorphous Alloy Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2.40 Billion |

| CAGR (2025-2032) | 7.3% |

| By Application |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Cobalt Based Amorphous Alloy market? +

In 2024, the Cobalt Based Amorphous Alloy market is USD 1.37 Billion.

Which is the fastest-growing region in the Cobalt Based Amorphous Alloy market? +

Europe is the fastest-growing region in the Cobalt Based Amorphous Alloy market.

What specific segmentation details are covered in the Cobalt Based Amorphous Alloy market? +

Application and End-Use segmentation details are covered in the Cobalt Based Amorphous Alloy market.

Who are the major players in the Cobalt Based Amorphous Alloy market? +

Toshiba Materials Co., Ltd. (Japan), Foshan Huaxin Microcrystalline Metal Co., Ltd. (China), Shenzhen Jufeng Solder Co., Ltd. (China), and VACUUMSCHMELZE GmbH & Co. KG (Germany) are some major players in the market.