Manufacturing Execution System Market Size:

Manufacturing Execution System Market size is estimated to reach over USD 40.34 Billion by 2032 from a value of USD 16.15 Billion in 2024 and is projected to grow by USD 17.80 Billion in 2025, growing at a CAGR of 10.8% from 2025 to 2032.

Manufacturing Execution System Market Scope & Overview:

Manufacturing execution system (MES) is a dynamic software system that monitors, tracks, documents, and controls the manufacturing process. The MES tracks a huge amount of data, which boosts production efficiency and saves costs. Moreover, MES generates realistic production schedules to maximize product flow and asset utilization. Further, MES offers a wide range of features such as resource allocation, document control, data collection and acquisition, and others, which are further driving the manufacturing execution system market.

How is AI Impacting the Manufacturing Execution System Market?

AI is profoundly transforming the Manufacturing Execution System (MES) market by enabling systems to become more proactive and intelligent. By analyzing vast amounts of real-time data from the factory floor, AI-powered MES solutions can perform predictive maintenance, anticipating equipment failures before they occur and minimizing costly downtime. AI also enhances quality control through computer vision, automatically detecting defects with greater accuracy and speed than human inspectors. Furthermore, it optimizes production scheduling by dynamically adjusting workflows and resource allocation based on real-time conditions, such as material availability and machine status. This shift from a reactive to a predictive and self-optimizing system is driving significant market growth and operational efficiency for manufacturers.

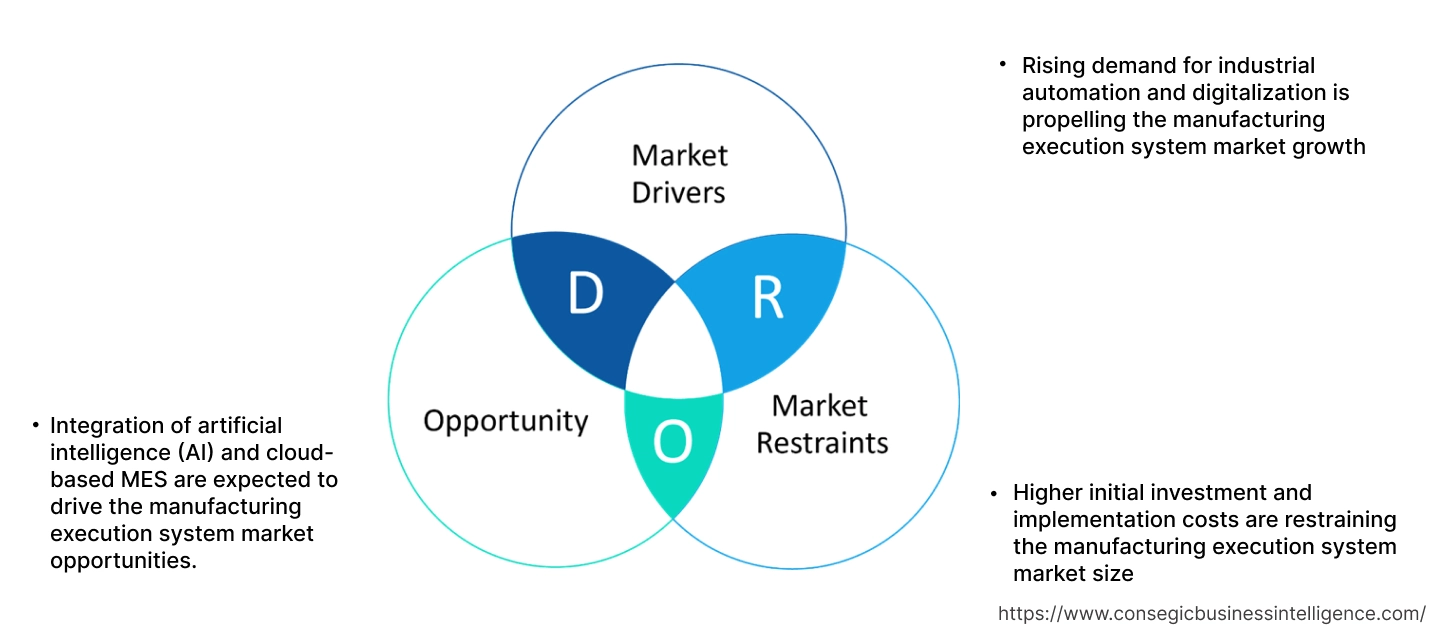

Manufacturing Execution System Market Dynamics - (DRO) :

Key Drivers:

Rising demand for industrial automation and digitalization is propelling the manufacturing execution system market growth

MES collects a vast amount of data on different aspects of production, including, machine production, material usage, product genealogy, and others. Control and automation play a crucial role in MES to automate tasks like scheduling, dispatching, and material handling, ensuring the production process runs smoothly. Moreover, MES provides real-time data analysis and reporting, which enables managers and other operators to make informed decisions.

- For instance, CAI Software offers MES solutions in its solution offerings. The company’s MES solutions facilitate advanced automation, real time production monitoring, quality management and others to improve productivity and operational efficiency.

Thus, the increasing adoption of industrial automation and digitalization is propelling the manufacturing execution system market expansion.

Key Restraints:

Higher initial investment and implementation costs are restraining the manufacturing execution system market size

High initial investment and implementation costs associated with MES are hindering the market. Moreover, the implementation of MES requires substantial upfront investment, including software licensing fees, hardware infrastructure, and system integration costs.

Additionally, MES often require customization to align with various industry requirements and production processes, adding to overall cost and complexity. Therefore, the aforementioned factors are hindering the market.

Future Opportunities :

Integration of artificial intelligence (AI) and cloud-based MES are expected to drive the manufacturing execution system market opportunities.

In MES, the integration of AI and cloud-based technologies enables a wide range of features like predictive analytics, real-time monitoring, and others to improve flexibility and scalability. Moreover, cloud-based MES offers real-time monitoring by providing manufacturers enhanced accessibility and real-time visibility to optimize production processes.

- For instance, in December 2022, Tulip launched cloud-based MES in AWS solutions library. Moreover, the cloud-based MES offers a wide range of benefits such as improved flexibility, scalability, and reliability among others.

Therefore, the integration of artificial intelligence and cloud-based MES is projected to boost the manufacturing execution system market opportunities during the forecast period.

Manufacturing Execution System Market Segmental Analysis :

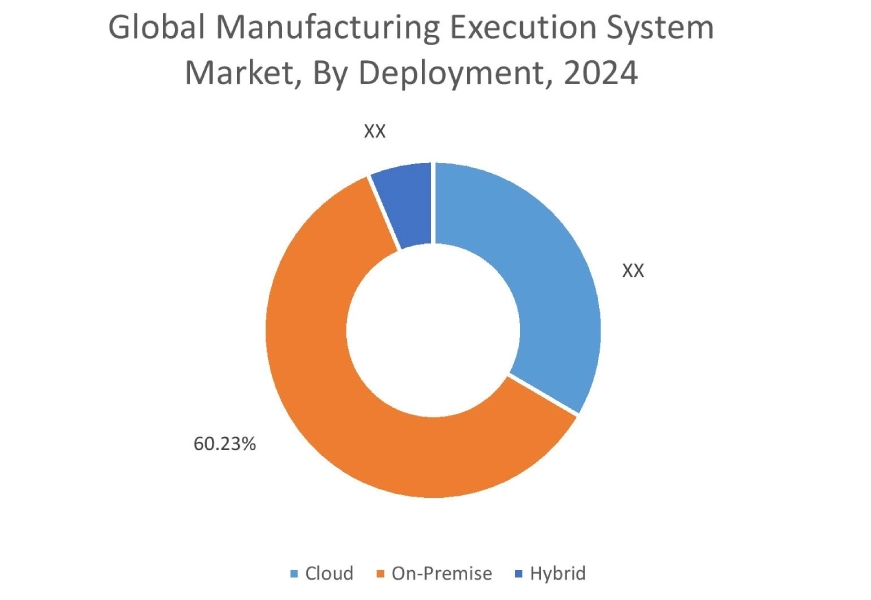

By Deployment:

Based on deployment, the market is segmented into cloud, on-premise, and hybrid.

Trends in the deployment:

- There is a rising trend towards the adoption of MES for improved quality control and production efficiency, which is further driving the manufacturing execution system market.

- Increasing trend in the adoption of MES due to its ability to track and collect real-time data is driving the manufacturing execution system market growth.

On-premise segment accounted for the largest revenue share of 60.23% in the overall manufacturing execution system market share in 2024.

- On-premise MES refers to a software solution that is installed and operated on organization’s physical servers and infrastructure.

- Moreover, on-premise systems offer manufacturers with more control over their data and infrastructure by providing enhanced security and compliance.

- Additionally, on-premise MES can be integrated with other enterprise resource planning to create a comprehensive and efficient manufacturing environment.

- Hence, rising advancements associated with on-premise MES are driving the market growth.

Cloud segment is anticipated to register the fastest CAGR growth during the forecast period.

- Cloud-based MES is a software solution that manages manufacturing operations using cloud technology.

- Moreover, cloud-based MES offers a wide range of benefits including reduced infrastructure cost, improved security, and enhanced IT resource utilization.

- Cloud-based MES solutions connect and control production process that collects real-time data from machines, operators, and other systems to track production.

- For instance, in October 2024, ECI Software Solutions announced the launch of cloud-based MES, which provides improved automation and advanced features such as visual planning, real-time data collection, and flexible scheduling.

- Hence, the above increasing innovations are projected to drive the manufacturing execution system market size during the forecast period.

By Application:

Based on application, the market is segmented into order management, detailed scheduling, quality control, and others.

Trends in the application:

- Increasing technological advancements associated with the integration of cloud-based MES in order management are driving the market demand.

- Increasing adoption of cloud-based MES to manage orders in various sectors including automotive, pharmaceuticals, and others due to their scalability and reduced upfront costs is a key trend driving the market growth.

Order management segment accounted for the largest revenue in the overall market share in 2024 and is anticipated to register a significant CAGR growth during the forecast period.

- MES is designed to manage, monitor, and control the process of manufacturing goods, providing a functional layer between enterprise resource planning (ERP) and process control systems.

- Moreover, order management software within the MES includes the process of receiving, tracking, and fulfilling customer orders by ensuring efficient production.

- Additionally, key aspects of order management in MES include work order management, real-time tracking, production scheduling, and others.

- For instance, ABB offers MES, which covers all order entry and invoicing functions that deal with the manufacturing processes. Moreover, this solution is designed mainly for pulp and paper industry for order management.

- Therefore, rising advancements related to MES software for order management applications are further projected to drive the market during the forecast period.

By End-Use:

Based on end use, the market is segmented into automotive, oil & gas, pharmaceuticals, metals & mining, medical, aerospace, and others.

Trends in end use:

- Increasing adoption of MES in automotive manufacturing for real-time monitoring, thermal management, and protection against over and under-voltage is driving the manufacturing execution system market trends.

- Factors including enhanced quality control, improved data management, and automated reporting are driving the manufacturing execution system market trends.

The pharmaceuticals segment accounted for the largest revenue in the overall manufacturing execution system market share in 2024.

- In the pharmaceutical sector, MES tracks and documents the entire manufacturing process for ensuring efficiency and accuracy.

- Moreover, MES manages and generates electronic batch records by eliminating the need for paper-based recorders.

- In addition, MES provides a comprehensive digital solution for pharmaceutical manufacturers by enabling them to optimize production, ensure compliance, and improve overall operational efficiency.

- For instance, in May 2025, Kober Pharma unveiled a wide range of offerings including PAS-X MES 3.4, PAS-X, and other solutions. Moreover, Kober transformed PAS X MES into a SaaS solution to support pharmaceutical operations.

- Therefore, according to the manufacturing execution system market analysis, the above factors are projected to boost the market during the forecast period.

Automotive segment is anticipated to register the fastest CAGR growth during the forecast period.

- In the automotive sector, MES provides real-time monitoring, data collection, and process automation, which helps manufacturers to synchronize operations across different workstations.

- MES tracks the process of vehicles that are present on the assembly line by monitoring workstations and components as they provide a line of view of the production process.

- Moreover, MES offers a wide range of benefits in the automotive sector such as improved quality control and traceability, inventory management, production scheduling, and others.

- Hence, according to the market analysis, the above factors are projected to boost the market during the forecast period.

Regional Analysis:

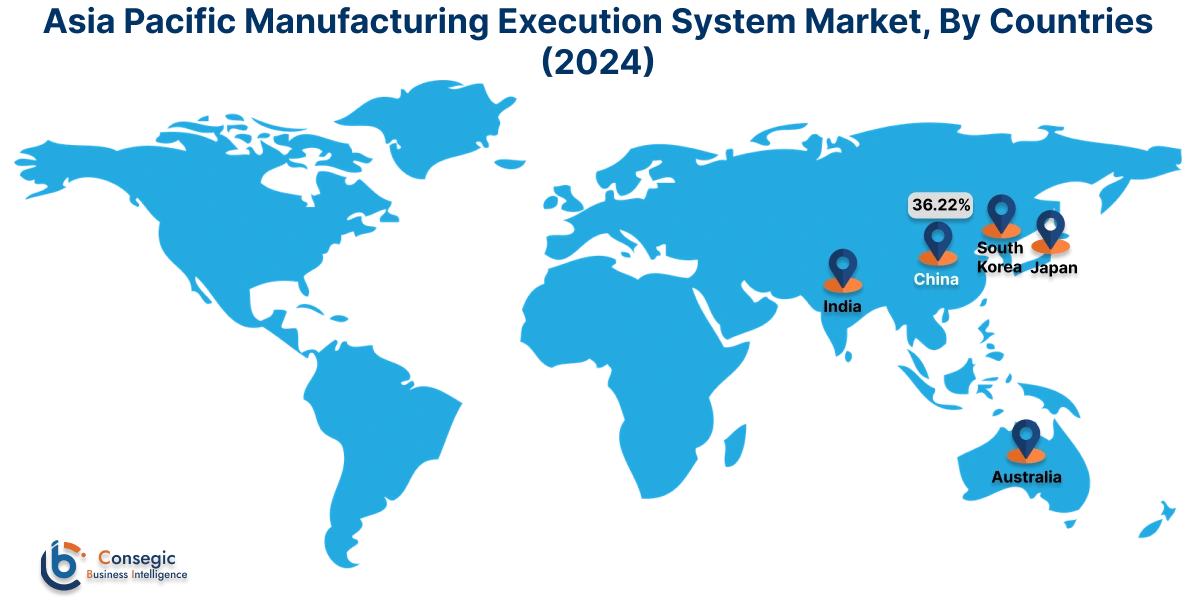

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

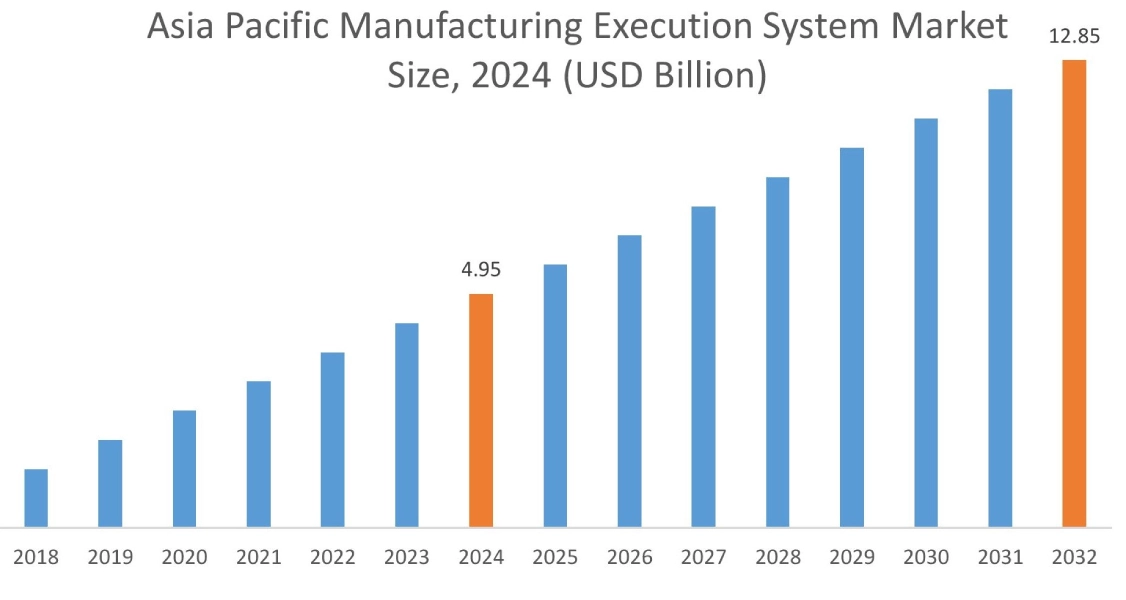

Asia Pacific region was valued at USD 4.95 Billion in 2024. Moreover, it is projected to grow by USD 5.47 Billion in 2025 and reach over USD 12.85 Billion by 2032. Out of this, China accounted for the maximum revenue share of 36.22%. As per the manufacturing execution system market analysis, the adoption of MES in the Asia-Pacific region is primarily driven by the rising demand for improved production efficiency in automotive, pharmaceuticals, oil and gas, and other sectors in the region. Additionally, the rising advancements in order management and growing integration of cloud-based MES are further accelerating the manufacturing execution system market expansion.

- For instance, Automators Industrial Projects Pvt Ltd offer MES designed to streamline manufacturing processes, enhance efficiency, and provide real-time visibility into operations. The above factors are driving the market in the Asia-Pacific region.

North America is estimated to reach over USD 13.84 Billion by 2032 from a value of USD 5.54 Billion in 2024 and is projected to grow by USD 6.11 Billion in 2025. In North America, the adoption of MES is driven by increasing adoption of detailed scheduling in healthcare sector and rising adoption of cloud-based MES in the region. Similarly, rising developments associated with automotive, pharmaceutical, and aerospace industries are contributing to the manufacturing execution system market demand.

- For instance, in October 2024, Sanmina Corporation, a U.S. based provider of cloud-based manufacturing execution systems, launched 42Q connected manufacturing. Moreover, key features of 42Q connected manufacturing include a unified data ecosystem, real-time analytics, and enhanced quality monitoring. The aforementioned factors are boosting the market in North America.

Additionally, the regional analysis depicts that the rising industrial automation and growing need for MES in automotive, healthcare, and oil & gas sectors, due to its improved efficiency and enhanced quality control, is driving the manufacturing execution system market demand in Europe. Furthermore, as per the market analysis, the market demand in Latin America, Middle East, and African regions is expected to grow at a considerable rate due to factors such as significant investments in oil & gas, healthcare, and other industrial sectors, increasing technological advancements, growing need for enhanced manufacturing process control solutions among others.

Top Key Players and Market Share Insights:

The global manufacturing execution system market is highly competitive with major players providing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the manufacturing execution system industry. Key players in the manufacturing execution system industry include-

- Vimachem (Greece)

- CAI Software, LLC (U.S.)

- Rockwell Automation (U.S.)

- Dassault Systems (France)

- Infosys (India)

- Schneider Electric (France)

- Zebra Technologies (U.S.)

- Jaggaer, LLC (U.S.)

- MPDV (U.S.)

- Siemens (Germany)

Recent Industry Developments :

Product Launch:

- In June 2025, Critical Manufacturing, a provider of modern manufacturing execution systems, announced its MES availability on Amazon Web Services (AWS). Moreover, this service offers manufacturers greater flexibility in operational goals through a cloud-based architecture.

Manufacturing Execution System Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 40.34 Billion |

| CAGR (2025-2032) | 10.8% |

| By Deployment |

|

| By Application |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the manufacturing execution system market? +

The manufacturing execution system market was valued at USD 16.15 Billion in 2024 and is projected to grow to USD 40.34 Billion by 2032.

Which is the fastest-growing region in the manufacturing execution system market? +

Asia-Pacific is the region experiencing the most rapid growth in the manufacturing execution system market.

What specific segmentation details are covered in the manufacturing execution systems report? +

The manufacturing execution systems report includes specific segmentation details for deployment, application, end use, and region.

Who are the major players in the manufacturing execution system market? +

The key participants in the manufacturing execution system market are Vimachem (Greece), CAI Software, LLC (U.S.), Schneider Electric (France), Zebra Technologies (U.S.), Jaggaer, LLC (U.S.), MPDV (U.S.), Siemens (Germany), Rockwell Automation (U.S.), Dassault Systems (France) and Infosys (India), and others.