Roll Forming Machines Market Size:

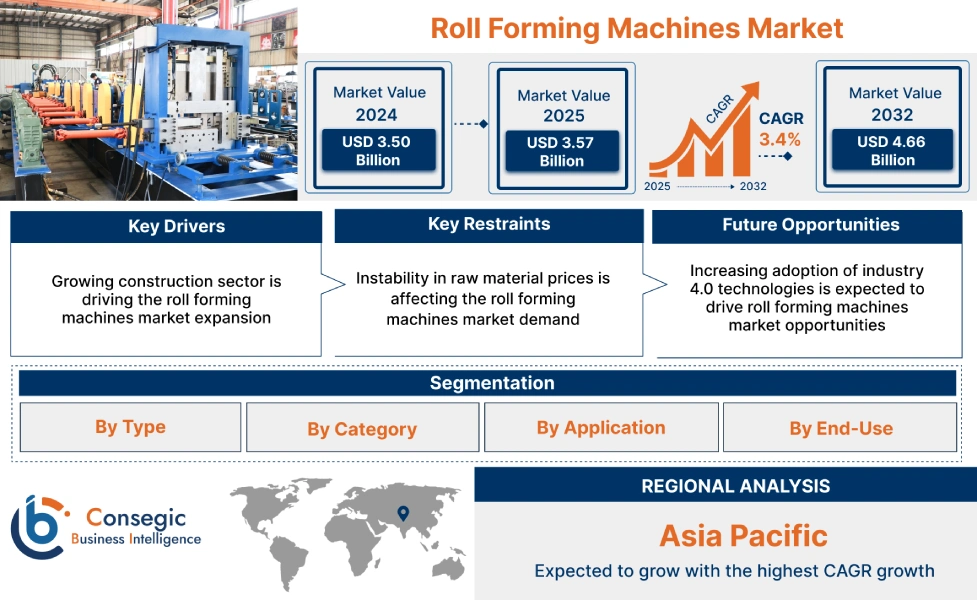

Roll Forming Machines Market Size is estimated to reach over USD 4.66 Billion by 2032 from a value of USD 3.50 Billion in 2024 and is projected to grow by USD 3.57 Billion in 2025, growing at a CAGR of 3.4% from 2025 to 2032.

Roll Forming Machines Market Scope & Overview:

Roll forming machines are equipment that uses a series of rollers to progressively bend a flat strip of metal into a desired, continuous profile. This process is used to create metal shapes in various industries, including construction and manufacturing. These machines are highly valued for their ability to produce complex shapes with high precision and efficiency, making them crucial in industries that require high-quality metal components.

How is AI Impacting the Roll Forming Machines Market?

AI is making roll forming machines smarter and more efficient. It is used to optimize production parameters in real-time, adjusting things like roller pressure and speed to minimize defects like spring back and wrinkling. This leads to higher product quality and less material waste. AI also enables predictive maintenance, with sensors on the machines constantly monitoring performance data to predict when a part might fail. This allows for proactive repairs, significantly reducing costly unplanned downtime. Furthermore, AI-powered computer vision systems can perform real-time quality control checks, instantly identify flaws and ensure products meet strict specifications. The integration of AI is transforming the industry by improving precision, reliability, and profitability.

Roll Forming Machines Market Dynamics - (DRO) :

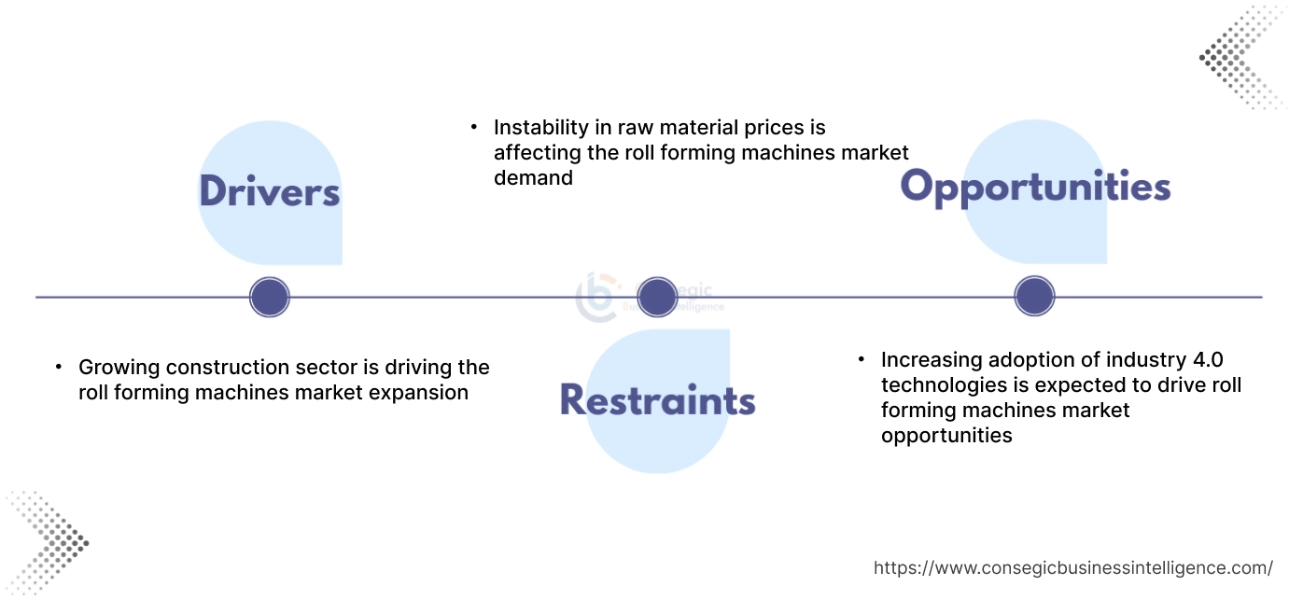

Key Drivers:

Growing construction sector is driving the roll forming machines market expansion

The construction sector is experiencing robust growth globally, driven by urbanization, infrastructure development, and renovation activities. This has led to an increasing demand for construction materials such as metal roofing, wall panels, and structural components, which further boosts the demand for automatic roll forming equipment. The ability of these machines to produce uniform and precise metal profiles efficiently makes them vital in the construction sector.

- For instance, Botou Zhongke’s channel roll forming machines are designed to meet the increasing need for high-quality roll-forming solutions in the construction sector. This machine has advanced technology and features, enabling it to precisely and consistently produce diverse channel profiles.

Thus, according to the roll forming machines market analysis, the growing construction sector is driving the roll forming machines market size.

Key Restraints:

Instability in raw material prices is affecting the roll forming machines market demand

The instability in raw materials is a critical factor influencing the global market. One of the significant restraints in this market is the limited availability and instability of high-quality raw material prices required for manufacturing durable and reliable products. These machines are heavily dependent on specific types of metals, such as high-strength steel and aluminum, which are essential for producing components that can withstand extreme conditions and heavy usage. Furthermore, the fluctuating prices of raw materials add another layer of complexity. The global supply chain for metals is often subject to geopolitical tensions, trade policies, and economic fluctuations, all of which can cause price volatility. Thus, the aforementioned factors would further impact the roll forming machines market size.

Future Opportunities :

Increasing adoption of industry 4.0 technologies is expected to drive roll forming machines market opportunities

The integration of advanced control systems, computer-aided design (CAD) software, and the Internet of Things (IoT) in roll forming solutions is enhancing their capabilities and making them more efficient and versatile. These technological advancements are reducing operational costs, minimizing material wastage, and enabling manufacturers to produce complex profiles with minimal human intervention. The growing focus on smart manufacturing and automation is expected to drive the demand for advanced roll forming equipment, creating opportunities for manufacturers to invest in new technologies and expand their market presence.

- For instance, Kingreal’s advanced automation and computer-aided design technologies for roll forming equipment enhance the quality of the finished product and maximize productivity by reducing rework and material waste.

Thus, based on the above roll forming machines market analysis, the increasing adoption of industry 4.0 technologies is expected to drive the roll forming machines market opportunities and growth.

Roll Forming Machines Market Segmental Analysis :

By Type:

Based on type, the market is segmented into single duty, standardized, side-by-side machines, double-headed machines, rafted machines, and others.

Trends in the type:

- The integration of automation, robotics, and digital technologies into roll forming equipment has enhanced their capabilities, which provide greater flexibility, precision, and productivity.

- As manufacturers strive to optimize their operations and meet the evolving needs of their customers, the global market is expected to grow in the upcoming years.

- Thus, based on the above analysis, these factors are driving the roll forming machines market demand.

The single duty segment accounted for the largest revenue share in the year 2024.

- Single duty machines are widely used due to their simplicity, cost-effectiveness, and ease of operation.

- They are ideal for small to medium-sized production runs and are commonly used in applications where a single type of profile is required.

- These machines can produce multiple profiles simultaneously, reducing the need for multiple machines and changeovers, thereby saving time and labor costs.

- For instance, Samco’s single duty machines are used for producing studs and tracks for drywall and light gauge steel framing, often used in construction. It features a fully programmable servo feeder for varied lengths, along with entry basket rolls and strip guides.

- Thus, based on the above analysis, these factors are further driving the roll forming machines market growth.

The double-headed machines segment is anticipated to register the fastest CAGR during the forecast period.

- A double-headed machine is a highly efficient and space-saving piece of equipment in the metal forming sector.

- A double-headed machine is designed with two independent sets of roll tooling arranged vertically (one above the other) on the same machine frame.

- Manufacturers are constantly seeking ways to reduce costs, improve quality, and increase speed to stay competitive. Double-headed machines offer a distinct advantage in these domains.

- Thus, based on the above analysis, these factors are expected to drive the roll forming machines market share and growth during the forecast period.

By Category:

Based on the category, the market is segmented into automatic and semi-automatic.

Trends in the category:

- The rising demand for high-quality, precisely formed metal components in construction, automotive, and other sectors is driving the adoption of automatic and semi-automatic machines.

- The trend towards electric vehicles (EVs) is further propelling the need for lightweight and durable metal parts, thereby fostering market growth.

The semi-automatic segment accounted for the largest revenue share in the year 2024.

- Semi-automatic machines are widely used in small to medium-sized production facilities where manual intervention is required for certain operations such as loading and unloading materials.

- These machines offer a good balance between cost and efficiency, making them suitable for manufacturers with limited budgets or production requirements.

- Semi-automatic machines are particularly popular in the construction and automotive industries, where they are used to produce various metal profiles with high precision and consistency.

- Thus, based on the above analysis, these factors would further supplement the roll forming machines market

The automatic segment is anticipated to register the fastest CAGR growth during the forecast period.

- Automatic machines are equipped with advanced control systems, sensors, and automation technologies that enable them to operate with minimal human intervention.

- Fully automatic machines can perform multiple operations such as material feeding, forming, cutting, and stacking in a single continuous process.

- This reduces the need for manual labor, minimizes material wastage, and ensures high precision and consistency in the produced profiles.

- These developments in the automatic machine segment are anticipated to further drive the roll forming machines market trends during the forecast period.

By Application:

Based on application, the market is segmented into frames, trusses & joists, modular construction, commercial construction, roofing systems, rapid building, and custom building.

Trends in the application:

- The increasing investment in renewable energy projects, such as solar and wind power, is driving the demand for metal components used in energy systems. Roll forming equipment is used to produce various components such as mounting structures, frames, and enclosures for solar panels and wind turbines.

- The ability to produce durable and precisely formed metal profiles efficiently is increasing the adoption of roll forming equipment in several industrial applications.

The commercial construction segment accounted for the largest revenue in the year 2024.

- Pre-engineered buildings (PEBs) are heavily reliant on roll-formed structural components and are becoming the ideal choice for commercial spaces like warehouses, factories, retail outlets, and even educational institutions. This trend is fueled by the ability to reduce build times by 30-50%.

- Roll forming equipment is becoming more automated, incorporating advanced programmable logic controller (PLC) and human machine interface (HMI) systems.

- Additionally, there is a growing shift towards connected machines with digitalization, enabling real-time monitoring, data analysis, and predictive maintenance.

- The integration of AI and machine learning for process optimization, digital twins for simulation and virtual commissioning, and cloud-based data analytics are emerging developments in advanced roll forming equipment for commercial construction applications.

- For instance, VIETSTEEL’s roll forming equipment offers high automation capabilities, while enhancing production efficiency and absolute precision. They are used in commercial constructions, factories, and warehouses.

- Consequently, the above factors are driving the roll forming machines market growth.

The roofing systems segment is anticipated to register the fastest CAGR growth during the forecast period.

- The development of new alloys, pre-painted metals (PPGI/PPGL), and advanced protective coatings for steel and aluminum makes metal roofing more durable, corrosion-resistant, and aesthetically versatile. Roll forming equipment is designed to handle these modern materials without damaging their finishes.

- Roll forming allows streamlined production from coil to finished product, minimizing waste and optimizing the supply chain for roofing materials. The ability to produce on-site further enhances supply chain resilience by reducing transportation complexities and costs.

- These factors are anticipated to further drive the roll forming machines market trends during the forecast period.

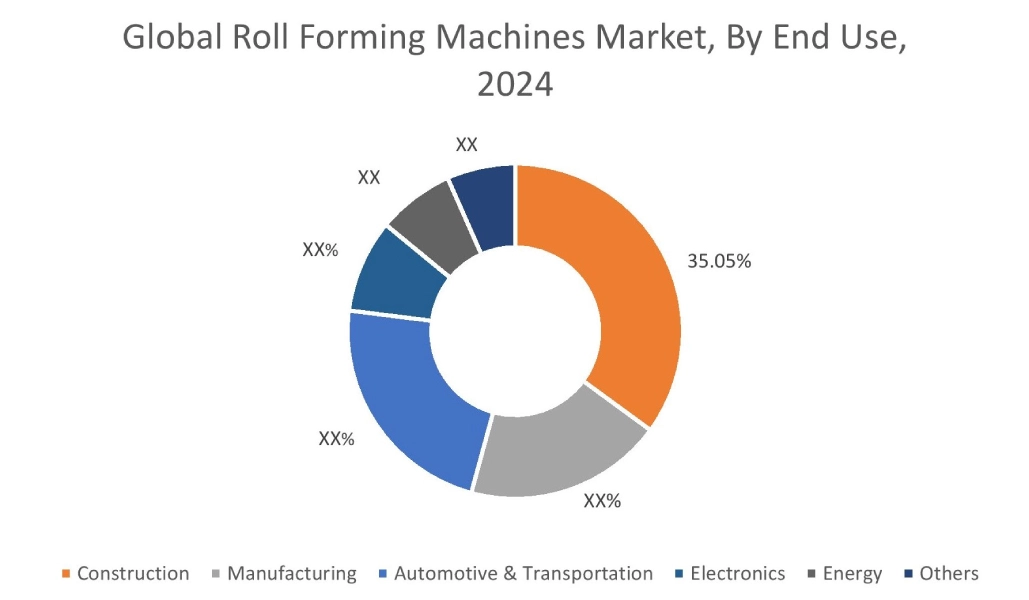

By End Use:

Based on end use, the market is segmented into construction, manufacturing, automotive & transportation, electronics, energy, and others.

Trends in the end use:

- The growing need for consumer electronics, telecommunications equipment, and renewable energy systems is driving the adoption of roll forming solutions in these sectors. The versatility and efficiency of roll forming machines make them suitable for a wide range of applications across various industries.

- The growing focus on smart manufacturing and automation is expected to drive the need for advanced roll forming equipment, creating prospects for manufacturers to invest in new technologies and expand their market presence.

The construction segment accounted for the largest revenue share of 35.05% in the year 2024 and it is expected to register the highest CAGR during the forecast period.

- Automatic roll forming equipment is extensively used in the construction sector to produce high-quality, precisely formed metal profiles that meet the stringent requirements of modern construction projects.

- The ability to produce customized profiles efficiently and cost-effectively makes these machines necessary in the construction sector.

- Moreover, roll forming machines are used to manufacture items like metal beams, channels, and panels, which are crucial for both residential, commercial, and industrial construction activities.

- As infrastructure projects and construction activities continue to expand globally, the need for efficient roll forming solutions in construction remains high.

- Thus, the above factors are driving the global market trends.

Regional Analysis:

The global market has been classified by region into North America, Europe, Asia-Pacific, Middle East & Africa, and Latin America.

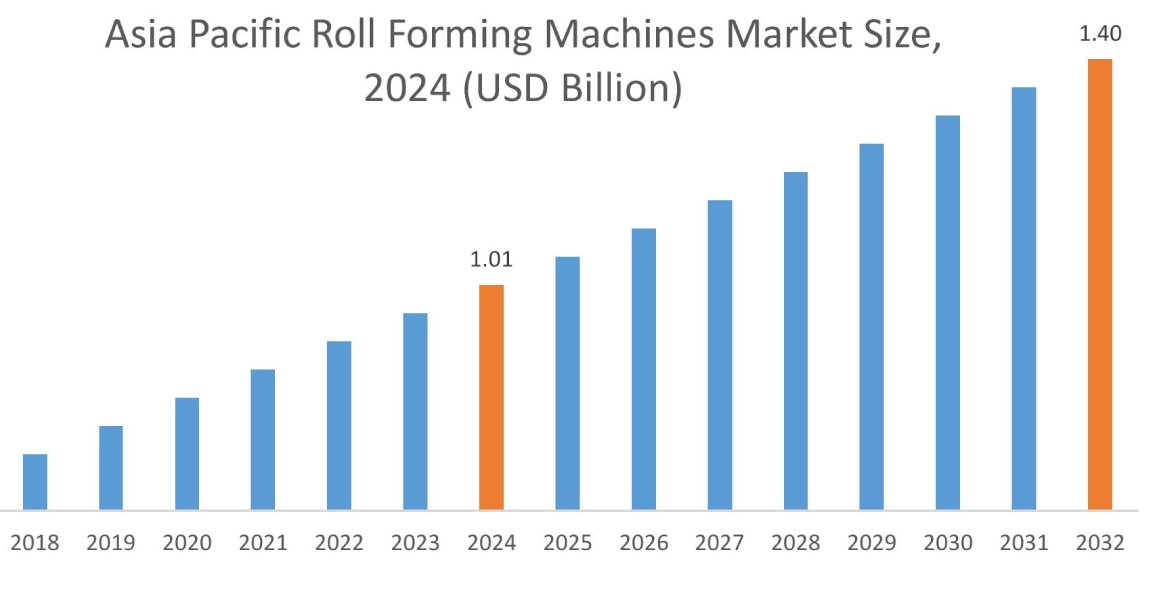

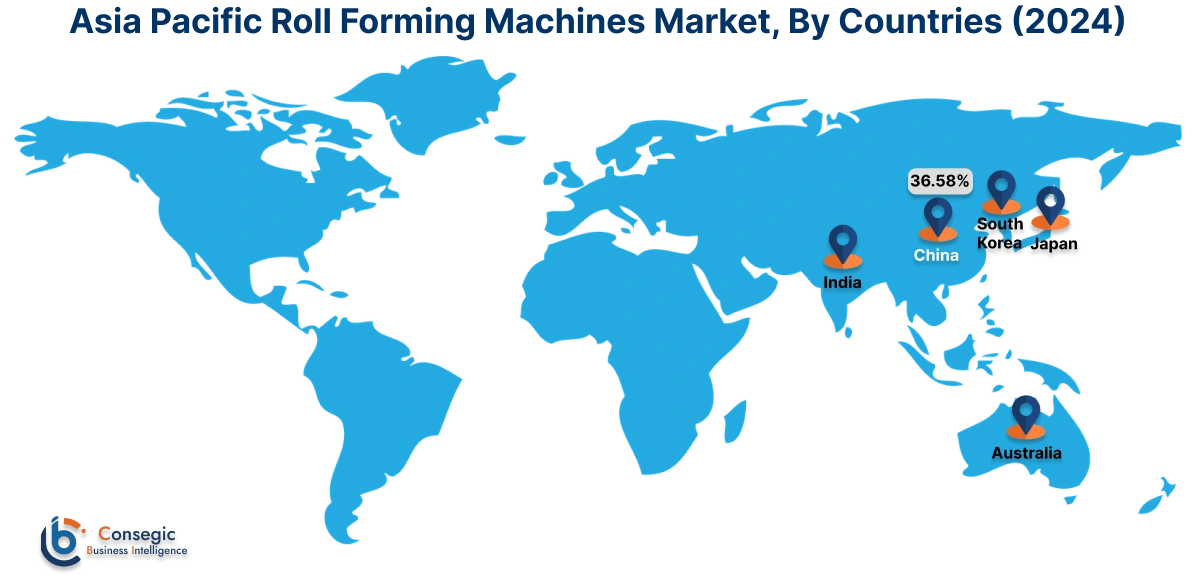

Asia Pacific roll forming machines market expansion is estimated to reach over USD 1.40 billion by 2032 from a value of USD 1.01 billion in 2024 and is projected to grow by USD 1.04 billion in 2025. Out of this, the China market accounted for the maximum revenue split of 36.58%. The expanding construction and infrastructure sectors, coupled with the growing automotive sector, is driving the need for roll forming solutions in the region. Additionally, favorable government policies and investments in manufacturing capabilities are propelling the adoption of roll forming machines. These factors would further drive the regional roll forming machines market during the forecast period.

- For instance, the Government of India is boosting its infrastructure sector by introducing initiatives, such as the National Infrastructure Pipeline (NIP), Make in India, and the Production-Linked Incentives (PLI) scheme, in order to attain its USD 5 trillion economy goal by 2025.

The North American market is estimated to reach over USD 1.65 billion by 2032 from a value of USD 1.24 billion in 2024 and is projected to grow by USD 1.27 billion in 2025. The region is witnessing increased investment in infrastructure development and renovation projects, boosting the need for construction materials such as metal roofing and wall panels. Further, the automotive sector in North America is also experiencing significant development, with automakers focusing on producing lightweight and electric vehicles. Moreover, the high adoption of advanced manufacturing technologies and automation in this region is driving the need for fully automatic roll forming solutions. These factors would further drive the market in North America.

- For instance, Samco, a North American company, offers roll-forming machines that enable manufacturing automotive profiles and components, such as side impact beams, chassis components, pillars, and bumpers. These solutions include features for in-line operations such as pre-punching, welding, and sweep units. They also offer flying cut-off systems that can handle both straight and swept parts, as well as closed and open sections, all within the continuous production process.

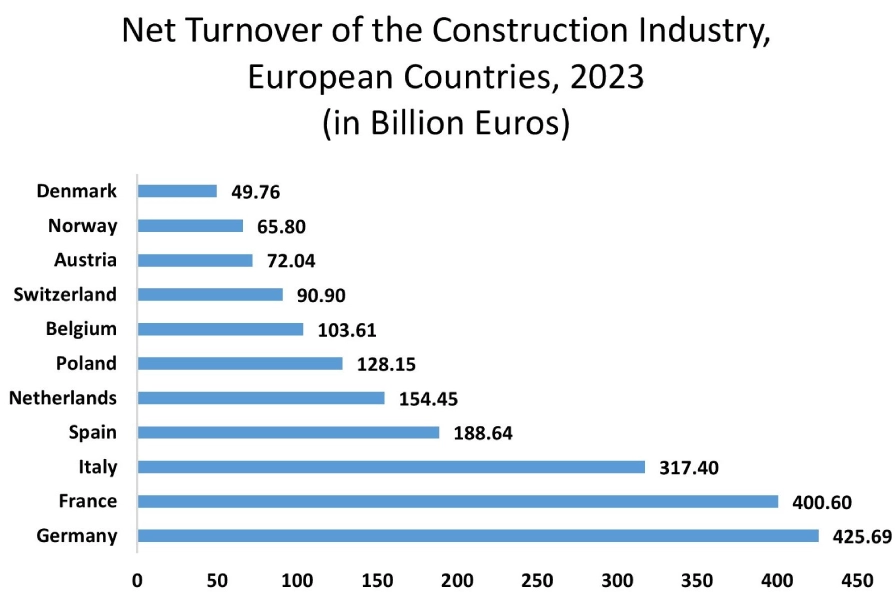

According to the analysis, the roll forming machines industry in Europe is anticipated to witness significant development during the forecast period. The increasing investment in renewable energy projects, such as solar and wind power, is driving the need for metal components used in energy systems, thereby propelling the market. Additionally, Latin American market benefits from a strong emphasis on automation and precision engineering, particularly in the automotive and aerospace sectors. Moreover, the increasing trend towards sustainable and energy-efficient building practices in the region supports the need for advanced roll forming technologies. Further, the increasing investment in renewable energy projects, such as solar and wind power, is driving the need for metal components used in energy systems, further boosting the market for roll forming machines in the Middle East & Africa.

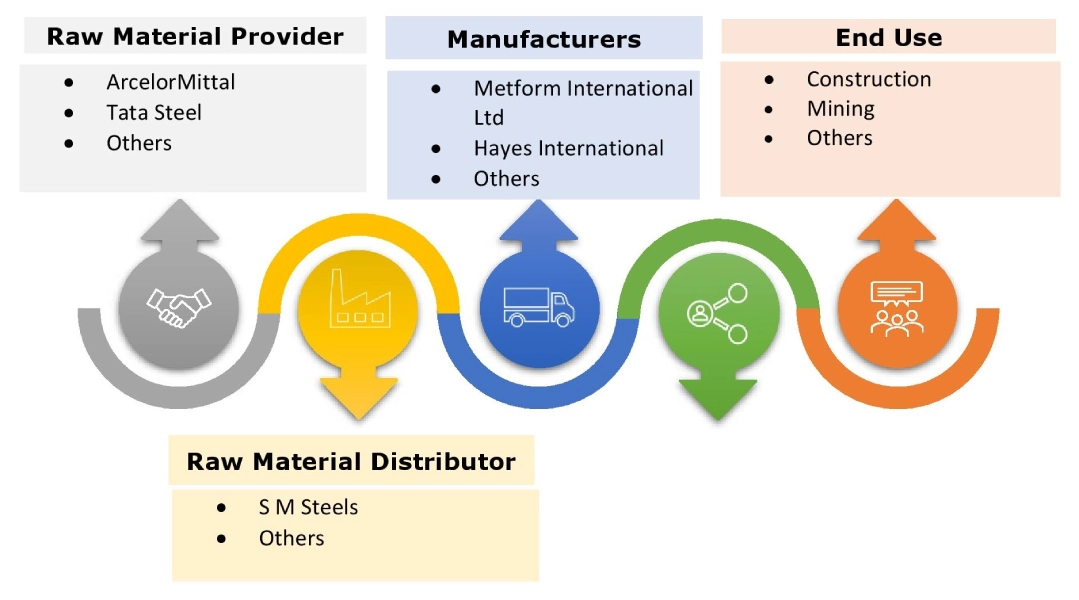

Top Key Players and Market Share Insights:

The global roll forming machines market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the roll forming machines industry include-

- Metform International Ltd (Canada)

- Hayes International (New Zealand)

- GASPARINI S.p.A. (Italy)

- Form Process Engineering (U.S.)

- Jupiter Roll Forming Pvt. Ltd. (India)

- Samco Machinery (Canada)

- Englert Inc. (U.S.)

- Zeman Bauelemente ProduktionsgesmbH (Austria)

- ASC Machine Tools Inc (U.S.)

- Howick Ltd (New Zealand)

Roll Forming Machines Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 4.66 Billion |

| CAGR (2025-2032) | 3.4% |

| By Type |

|

| By Category |

|

| By Application |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Roll Forming Machines Market? +

Roll Forming Machines Market Size is estimated to reach over USD 4.66 Billion by 2032 from a value of USD 3.50 Billion in 2024 and is projected to grow by USD 3.57 Billion in 2025, growing at a CAGR of 3.4% from 2025 to 2032.

Which is the fastest-growing region in the Roll Forming Machines Market? +

Asia-Pacific region is experiencing the most rapid growth in the market.

What specific segmentation details are covered in the Roll Forming Machines report? +

The roll forming machines report includes specific segmentation details for type, category, application, end use, and region.

Who are the major players in the Roll Forming Machines Market? +

The key participants in the market are Metform International Ltd (Canada), Hayes International (New Zealand), Samco Machinery (Canada), Englert Inc. (U.S.), Zeman Bauelemente ProduktionsgesmbH (Austria) , ASC Machine Tools Inc (U.S.), Howick Ltd (New Zealand), GASPARINI S.p.A. (Italy), Form Process Engineering (U.S.), Jupiter Roll Forming Pvt. Ltd. (India), and others.