Vapor Recovery Unit Market Size:

Vapor Recovery Unit Market size is growing with a CAGR of 3.7% during the forecast period (2025-2032), and the market is projected to be valued at USD 1.44 Billion by 2032 from USD 1.09 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 1.12 Billion.

Vapor Recovery Unit Market Scope & Overview:

A vapor recovery unit (VRU), also called a vapor recovery system, is designed to capture and recover volatile organic compounds (VOCs) that would otherwise be released into the atmosphere from industrial processes and storage tanks. The key components typically include a compressor (e.g., rotary screw, reciprocating) to draw in and compress the vapors, a scrubber/separator to remove liquids and impurities, and a condenser or activated carbon beds to convert vapors back into liquid or adsorb them. They are widely used in the oil and gas sector, petrochemical plants, and landfills to capture valuable hydrocarbons and hazardous air pollutants. They offer significant benefits by reducing harmful emissions, recovering valuable products, and enhancing safety by mitigating fire and explosion hazards associated with fugitive vapors.

How is AI Transforming the Vapor Recovery Unit Market?

AI is transforming the Vapor Recovery Unit (VRU) market by enabling predictive maintenance to reduce downtime, optimizing recovery efficiency for higher fuel resale value, and automating regulatory compliance reporting. Also, AI helps automate reporting and flag anomalies, ensuring VRUs consistently meet stringent EPA and environmental regulations. Further, AI enables remote monitoring and control of VRUs across multiple sites, as well as utilizing digital twin models for virtual simulation and performance forecasting. Hence, AI integration leads to lower operational costs, improved energy efficiency, and better environmental protection.

Vapor Recovery Unit Market Dynamics - (DRO) :

Key Drivers:

Booming Oil & Gas Exploration is Accelerating Vapor Recovery Unit Market Expansion.

Vapor recovery units in oil and gas are commonly installed at wellheads, tank batteries, gathering stations, and pipeline pig launching/receiving sites. They recover methane and other volatile organic compounds (VOCs) that flash off crude oil and condensate tanks due to pressure and temperature changes. This reduces harmful greenhouse gas emissions and air pollution. It also ensures regulatory compliance and converts a waste product into a valuable sellable commodity or fuel gas for on-site use. Global energy demand is rising due to industrialization and population increase. This has led to an increase in the sector, hence requiring these recovery units for multiple applications.

For instance,

- According to the Energy Information Administration, U.S. natural gas production increased by approximately 4% in 2023 compared to the previous year, thus positively impacting vapor recovery unit market trends.

Overall, booming oil & gas exploration is significantly boosting vapor recovery unit market expansion.

Key Restraints:

Growing Commercialization of Alternative Emission Control Technologies is Hampering the Vapor Recovery Unit Market Demand.

The market faces hurdles from the substitutes available in the market. For instance, flares are widely used for the safe combustion of excess, unrecoverable, or emergency gas releases. They are relatively simple to operate and cost-effective for large-volume releases where recovery is not economically viable. They act as crucial safety devices for pressure relief. Moreover, thermal oxidizers destroy VOCs by incinerating them at high temperatures, converting them into less harmful substances such as CO2 and water vapor. They offer very high destruction efficiency (99%+). This makes them suitable for streams with high VOC concentrations or hazardous air pollutants (HAPs). They are highly energy-efficient due to their heat recovery capabilities. Additionally, bio-filters use microorganisms to break down VOCs and odors in a moist filter bed. They are an environmentally friendly and low-cost option for treating large volumes of air with low concentrations of biodegradable VOCs. They have very low energy consumption and produce minimal hazardous byproducts. Hence, the growing commercialization of alternative emission control technologies is hampering the vapor recovery unit market demand.

Future Opportunities :

Expanding Biofuels Production is Expected to Vapor Recovery Unit Market Opportunities.

During various stages of biofuel production, particularly fermentation, distillation, and storage of ethanol and other bio-alcohols, significant amounts of VOCs are released. The vapor recovery system captures these valuable organic vapors and prevents their release into the atmosphere. This not only ensures environmental compliance with air quality regulations but also allows for the recovery of a portion of the product (e.g., ethanol vapor) that would otherwise be lost. By re-condensing and adsorbing these vapors, they contribute to improved process efficiency and potentially enhance overall yields, making biofuel production more sustainable and economically viable. The need to reduce greenhouse gas emissions and enhance energy security will lead to increased demand for biofuel, increasing production, hence positively influencing vapor recovery unit market trends.

For instance,

- According to the International Energy Agency, global biofuel demand is projected to surge by 38 billion liters between 2023 and 2028.

Overall, the expanding biofuel production is expected to increase the vapor recovery unit market opportunities.

Vapor Recovery Unit Market Segmental Analysis :

By Technology:

Based on technology, the market is categorized into carbon adsorption, membrane separation, condensation, absorption, and others.

Trends in Technology:

- A growing trend is the development of VRUs capable of recovering vapors from multiple sources such as high-pressure separators and low-pressure stock tanks) simultaneously.

- Manufacturers focusing on designing more energy-efficient components for carbon adsorption units to lower operational costs is also a rising trend.

The carbon adsorption segment accounted for the largest market share in 2024

- Carbon adsorption is a widely utilized technology in VRUs. It operates on the principle of adsorption, where VOCs physically adhere to the surface of a solid adsorbent material, typically activated carbon.

- Carbon adsorptions are known for their ability to achieve very high VOC recovery rates, exceeding 95-99%, leading to significant product recovery and emission reduction.

- Moreover, compared to some other VRU technologies, carbon adsorption systems are generally simpler to operate and maintain, requiring less complex control logic once set up.

- Additionally, it is a mature and well-established technology with decades of operational history, demonstrating its reliability and robustness in various industrial environments, hence driving its increased usage.

- Overall, as per the market analysis, the aforementioned factors are driving segmental growth in the market.

The membrane separation segment is expected to grow at the fastest CAGR over the forecast period.

- Membrane separation in VRUs selectively captures VOCs from gas streams using semi-permeable membranes driven by pressure differences.

- This technology excels in energy efficiency and offers a compact, modular design with low maintenance due to fewer moving parts.

- It eliminates the need for chemicals, provides high selectivity for VOC recovery, and flexibly handles varying VOC concentrations.

- There is greater awareness of these recovery units which are being driven by industry webinars and extensive online posts highlighting their benefits, hence driving segmental share.

- For instance, Mansfield Energy Corp. published an article in 2025 detailing vapor recovery unit, explaining what they are, what is membrane separation technology and how they function, while also clarifying the methods by which emissions reductions are achieved.

- Overall, as per the market analysis, the aforementioned factors will drive a segment in the vapor recovery unit market growth.

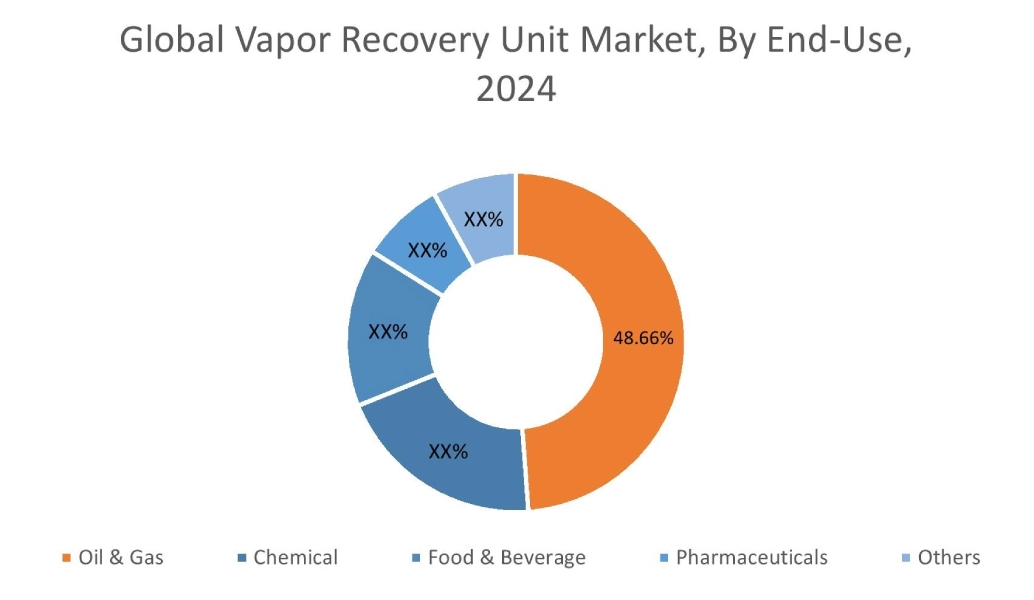

By End-Use:

Based on end-use, the market is categorized into oil & gas, chemical, food & beverage, pharmaceuticals, and others.

Trends in the End-Use

- There is an increasing trend of using vapor recovery systems inpetrochemical facilities to recover high-value chemical vapors from various processes and storage tanks.

- The usage of vapor recovery systems in food & beverages to control strong odors and to recover valuable aromas is also a rising trend.

The oil & gas segment accounted for the largest market share of 48.66% in 2024.

- In the oil and gas industry,vapor recovery systems significantly reduce the release of volatile organic compounds and methane, a potent greenhouse gas, into the atmosphere.

- By capturing and recycling valuable hydrocarbons such as natural gas and natural gas liquids, they lead to substantial economic savings.

- Moreover, they help oil and gas operators meet increasingly stringent environmental regulations, avoiding potential penalties and demonstrating a commitment to sustainability.

- Additionally, they minimize product loss and improve overall operational efficiency by recovering valuable resources and reducing the need for flaring or venting, hence driving its increased usage in the sector.

- Overall, as per the market analysis, the aforementioned factors are driving segmental growth in the vapor recovery unit industry.

The chemical segment is expected to grow at the fastest CAGR over the forecast period.

- Vapor recovery systems are crucial in the chemical sector for managing highly volatile and other hazardous organic compounds.

- They are deployed across various stages, from storage tanks to processing units such as during distillation, cracking, or polymerization.

- This not only safeguards air quality and worker health but also enables the recovery of valuable chemical feedstocks, improving overall process efficiency and economic returns. Expansion in the sector will drive more need for these units.

- For instance, according to IBEF, the Indian chemical market is expected to grow at a CAGR of 11-12% by 2027 from 2023.

- Thus, according to market analysis, the aforementioned factors will drive the segment in the vapor recovery unit market growth.

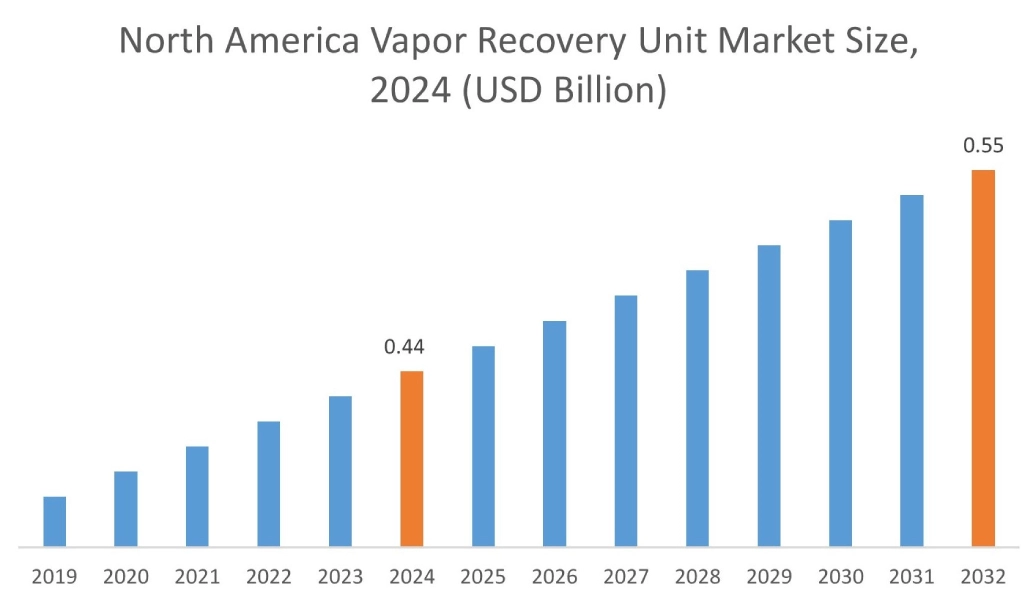

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, North America accounted for the highest vapor recovery unit market share at 40.12% and was valued at USD 0.44 Billion and is expected to reach USD 0.55 Billion in 2032. In North America, the U.S. accounted for the vapor recovery unit market share of 72.18% during the base year of 2024. There is an ongoing increase in oil and gas activities in the region. This heightened activity, from wellheads to extensive pipeline networks and storage terminals, generates substantial volumes of volatile organic compounds (VOCs).

For instance,

- According to the Energy Information Administration, in the first half of 2023, U.S. drillers significantly ramped up their activity, spudding 12% more new wells than in the same period of 2022.

By capturing flammable vapors, vapor recovery units reduce explosion and fire hazards. This improves safety for workers and surrounding communities. Moreover, they minimize product loss, contributing to overall operational efficiency and sustainability goals within the sector. Overall, growing oil and gas activities are driving the market in the region.

In Asia Pacific, the vapor recovery unit market is experiencing the fastest growth with a CAGR of 4.9% over the forecast period. There are growing chemical and petrochemical industries in the region. Countries such as China, India, and South Korea are experiencing massive industrial development, leading to increased production of commodity chemicals, specialty chemicals, and various petrochemical products. Vapor recovery unit is becoming important in these facilities to meet evolving environmental regulations aimed at controlling air pollution and hazardous emissions. By capturing and recovering these valuable chemical vapors, they not only ensure compliance but also improve raw material utilization and operational efficiency for these expanding industries.

Europe vapor recovery unit market analysis indicates that several key trends are contributing to its growth in the region. The pharmaceutical sector is rapidly expanding in the region. Pharmaceutical processes involve the use and handling of various volatile organic solvents during synthesis, purification, and formulation. Strict European environmental regulations, such as those related to industrial emissions (IED), mandate the control and reduction of these emissions. Vapor recovery systems are deployed in pharma facilities to capture solvent vapors from reactors, dryers, and storage tanks, ensuring compliance, preventing air pollution, and in some cases, recovering valuable solvents for reuse, thereby enhancing both environmental performance and cost efficiency. Countries such as Germany, France, and UK lead the market.

Middle East and Africa (MEA) vapor recovery unit market analysis indicates that the region is witnessing an emerging growth in biofuel production. Countries in the MEA such as UAE and Saudi Arabia are exploring and investing in projects to diversify their energy mix and enhance energy security. Biofuel production processes, particularly those involving fermentation and distillation of bioethanol and biodiesel, release significant amounts of volatile organic compounds. Vapor recovery systems are essential here to capture these vapors, ensuring compliance with evolving environmental standards and recovering valuable products that would otherwise be lost. This trend aligns with regional sustainability goals and efforts to develop new industrial sectors.

Latin America's region creates potential for the market, as it is increasingly driven by technological advancements in systems. There is a growing demand for more efficient, reliable, and cost-effective emission control solutions. Innovations such as improved compressor designs, advanced membrane separation technologies, enhanced control systems (including IoT integration), and more robust materials are making these systems more attractive. These advancements enable higher recovery rates, reduce operational and maintenance costs, and provide greater flexibility for various applications, directly supporting Latin America's efforts to modernize its industrial infrastructure while meeting environmental compliance. Countries such as Brazil and Argentina lead the market.

Top Key Players and Market Share Insights:

The Vapor Recovery Unit market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Vapor Recovery Unit market. Key players in The Vapor Recovery Unit industry include-

- Dover Fueling Solutions (United States)

- AEREON (Italy)

- Cool Sorption A/S (Denmark)

- Kilburn Engineering Ltd. (India)

- TECAM Group (Spain)

- Garo Srl (Italy)

- John Zink Hamworthy Combustion (United States)

- Cimarron Energy, Inc. (United States)

- Zeeco, Inc. (United States)

- Flogistix, LP (United States)

- Reynold India Pvt. Ltd. (India)

- SCS Technologies, LLC (United States)

Recent Industry Developments :

Product Launch:

- SCS Technologies launched a new line of pre-engineered vapor recovery unit. It is designed for enhanced efficiency, handling a wide range of flow rates and pressure, and is built to comply with EPA 0000a regulations. They feature a variable speed drive, bypass recycle valve, large scrubbers, and enhanced filtration, aiming for optimal runtime and addressing environmental concerns.

Vapor Recovery Unit Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 1.44 Billion |

| CAGR (2025-2032) | 3.7% |

| By Technology |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Vapor Recovery Unit market? +

In 2024, the Vapor Recovery Unit market is USD 1.09 Billion.

Which is the fastest-growing region in the Vapor Recovery Unit market? +

Asia Pacific is the fastest-growing region in the Vapor Recovery Unit market.

What specific segmentation details are covered in the Vapor Recovery Unit market? +

Technology and End-Use segmentation details are covered in the Vapor Recovery Unit market.

Who are the major players in the Vapor Recovery Unit market? +

Dover Fueling Solutions (United States), AEREON (Italy), John Zink Hamworthy Combustion (United States), Cimarron Energy, Inc. (United States), Zeeco, Inc. (United States), and Flogistix, LP (United States) are some major players in the market.