Ceramic Core Market Size:

The Ceramic Core Market size is growing with a CAGR of 4.0% during the forecast period (2025-2032), and the market is projected to be valued at USD 247.82 Million by 2032 from USD 181.70 Million in 2024. Additionally, the market value for 2025 is attributed to USD 188.32 Million.

Ceramic Core Market Scope & Overview:

A ceramic core is a highly specialized component used within the investment casting process. Its purpose is to create intricate internal passages, cavities, or complex geometries within a metal casting. During manufacturing, this pre-formed ceramic shape is integrated into a wax pattern. After the outer ceramic shell mold is built around it and the wax is melted out, the core remains inside the mold. Developed using various materials such as silica, zirconia, and alumina these cores are engineered for exceptional refractoriness, precise dimensional stability at high temperatures, and easy removability.

How is AI Impacting the Ceramic Core Market?

AI is significantly impacting the ceramic core market by optimizing various stages of the production lifecycle, from design and manufacturing to quality control and supply chain management. Also, AI-powered tools are enabling faster prototyping, improved precision, and increased efficiency, ultimately leading to higher quality products and reduced costs. Additionally, AI-powered systems can detect defects in real-time during production, minimizing waste and ensuring consistent product quality.

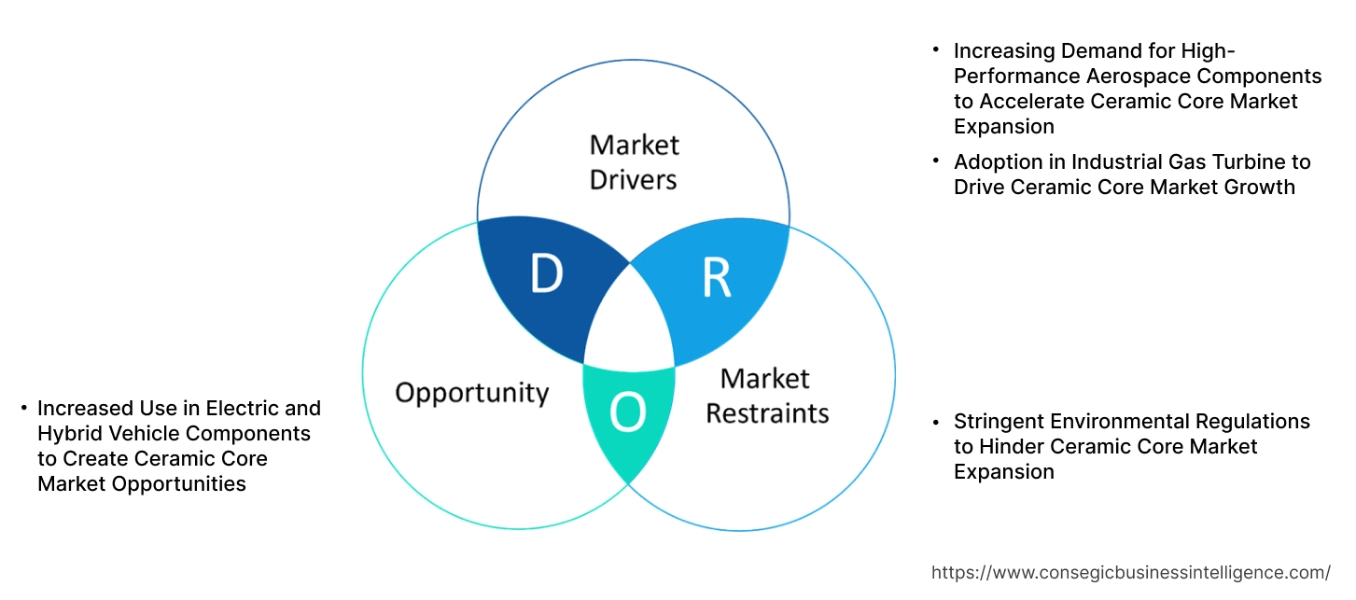

Ceramic Core Market Dynamics - (DRO) :

Key Drivers:

Increasing Demand for High-Performance Aerospace Components to Accelerate Ceramic Core Market Expansion.

As aircraft manufacturers focus on enhanced fuel efficiency, reduced emissions, and increased operational longevity, there's a critical need for advanced aero-engine parts capable of withstanding extreme temperatures and pressures. Ceramic cores are crucial in these applications, enabling the precise creation of intricate internal cooling passages within single-crystal turbine blades through investment casting. These complex internal geometries are vital for dissipating heat, allowing engines to run hotter and more efficiently, thereby fueling the growth and technological advancement within the ceramic core market analysis.

- For instance, in 2022, S. Economic Development Administration provided approximately USD 40 million in grants to the West Texas Aerospace and Defense Manufacturing Coalition to integrate local manufacturers into the aerospace and defense supply chain and enhance American manufacturing capabilities.

Thus, as per analysis, the reliance of the aerospace sector on these cores directly results in sustained adoption, propelling its market growth.

Adoption in Industrial Gas Turbine to Drive Ceramic Core Market Growth.

Ceramic cores are crucial parts for manufacturing intricate internal cooling passages and complex geometries within industrial gas turbine (IGT) components such as turbine blades and vanes. These precisely formed internal structures allow the turbines to withstand extreme thermal and mechanical stresses, enhancing their performance, durability, and overall fuel efficiency. IGTs are crucial for power generation, oil and gas operations. As global energy need continues to rise, there's a strong push for IGTs capable of operating at higher temperatures with greater efficiency and reduced emissions.

- For instance, the report by IEA indicates a global energy demand increase of 2.2% in 2024, a rate notably higher than the 1.3% average annual increase observed between 2013 and 2023.

Thus, the growing adoption of these core parts in advanced manufacturing in IGT sector is driving the ceramic core market growth.

Key Restraints:

Stringent Environmental Regulations to Hinder Ceramic Core Market Expansion.

The ceramic core industry faces a significant constraint on its upward trajectory due to the increasing environmental concerns and stringent regulatory oversight due to the complex manufacturing processes involved in production. The manufacturing process of ceramic cores, particularly the firing and leaching stages, involve energy-intensive processes and the use of certain chemicals that present environmental implications. Growing global emphasis on reducing industrial emissions, managing hazardous waste, and conserving energy forces manufacturers to invest heavily in advanced pollution control technologies and cleaner production methods. These compliance costs along with the complexities of obtaining permits and adhering to evolving regulations increase operational expenses. Overall, aforementioned factors restrain overall market growth.

Future Opportunities :

Increased Use in Electric and Hybrid Vehicle Components to Create Ceramic Core Market Opportunities.

As the automotive industry electrifies there's an increased need for components capable of handling high thermal loads, providing superior electrical insulation, and contributing overall vehicle lightweighting to extend range. Ceramic cores are finding new applications in thermal management solutions for batteries and power electronics, compact and efficient motor designs, and in lightweight structural elements among others. Their distinguishing properties such as high temperature resistance, excellent electrical insulation, among others make them suitable for managing the unique challenges of growing EV production, thereby opening up new avenues for market.

- For instance, new IEA report indicates that global electric car sales are projected constitute over a quarter of worldwide car sales, and are on track to surpass a 40% market share by 2030.

As a result, as per analysis, the growing adoption of EVs benefits the ceramic core market analysis.

Ceramic Core Market Segmental Analysis :

By Type:

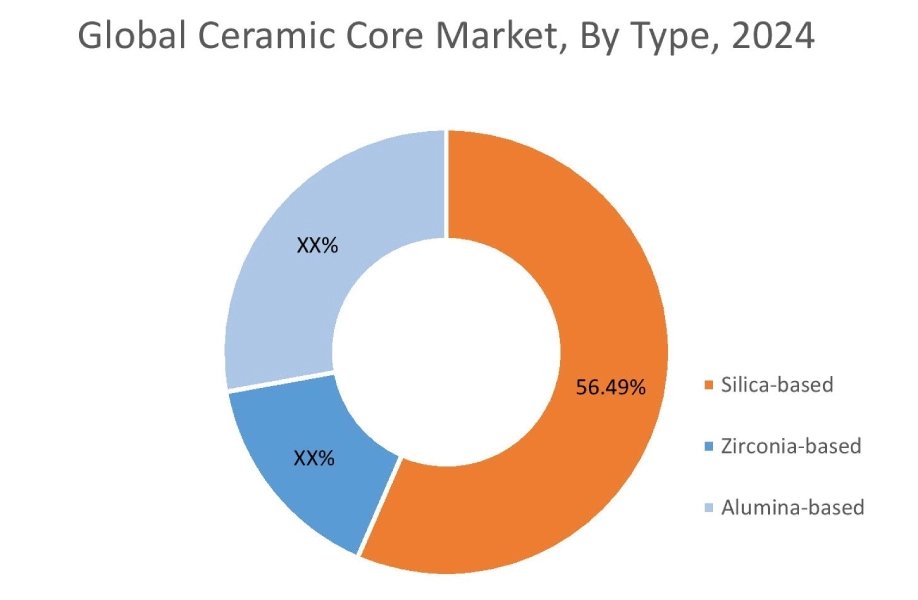

Based on type, the market is categorized into silica-based, zirconia-based, and alumina-based.

Trends in the Type:

- Rising demand for cost-effective solutions for moderate-temperature investment casting applications is a key trend.

- Growing adoption in high-performance aerospace and industrial gas turbine components that require superior refractoriness and strength.

The silica-based segment accounted for the largest ceramic core market share of 56.49% in 2024.

- Silica-based ceramic cores manufactured from fused silica serve key role in investment casting due to their dimensional stability and low thermal expansion.

- They also exhibit good chemical inertness against common alloys and offer advantageous leachability that simplifies their removal from solidified castings.

- Their cost-effectiveness, good thermal shock resistance, and ease of removal make them widely utilized in turbine engine cavities, gas turbine hollow blades, and various industrial components requiring precise internal passages.

- For instance, as per data published by the European Defense Agency, in 2023, European Union Member States collectively spent a total of USD 301.77 billion on defense, marking a significant increase in overall defense expenditure.

- Collectively, aforementioned factor are influencing the silica-based segment in the ceramic core market demand.

The Zirconia-based segment is expected to grow at the fastest CAGR over the forecast period.

- Zirconia-based ceramic cores, renowned for their exceptional refractoriness and strength at elevated temperatures, are indispensable for casting reactive alloys and operations involving very high melt temperatures.

- These cores with finer particle size and dense structure also contribute to a superior surface finish on the final metal part.

- Capable of withstanding temperatures exceeding 1600°C, they exhibit excellent chemical inertness, particularly with superalloys containing elements like titanium.

- Their properties are crucial for advanced aerospace components securing their position as growing market segment for high-value components.

By End Use:

Based on the end use, the market is categorized into aerospace & defense, automotive, healthcare, energy & power, and others.

Trends in the End Use:

- Rising requirement for advanced cooling passages in next-generation turbine blades to enable higher operating temperatures and fuel efficiency is a key trend.

- Focus on thermal management solutions in EV battery packs and power electronics to improve efficiency and range is a trend positively impacting the market.

The aerospace & defense segment accounted for the Ceramic Core market share in 2024.

- The aerospace & defense sector stands as the prominent end-use segment driven by the manufacturing of critical components for commercial aircraft, military jets, and defense systems.

- Ceramic cores are crucial here, enabling the creation of parts that endure extreme temperatures and pressures in jet engines.

- These complex geometries are crucial for enhancing component durability, boosting engine efficiency, and improving overall aircraft performance

- Hence, as per analysis, several factors such as increasing global air travel, rising military expenditures, and the continuous development of next-generation, fuel-efficient aero-engines ensure this segment dominates the ceramic core market demand.

The automotive segment is expected to grow at the fastest CAGR over the forecast period.

- In automotive, ceramic core serves as a key base for high-performance and specialty vehicles. They are used for casting components with complex internal geometries in advanced engine parts, turbochargers, and in the evolving landscape of electric and hybrid vehicle components.

- A continuous necessity for lighter, more durable, and fuel-efficient components in internal combustion engines, coupled with increasingly stringent emission regulations necessitating optimized designs drive segment revenue.

- This innovation in vehicle design and the accelerating trend towards electrification are poised to fuel adoption of these cores in the automotive sector.

- For instance, according to IEA, sales of electric vehicles worldwide are expected to surpass around 20 million in 2025.

- Hence, as per analysis, agrochemicals segment is growing at fastest rate in the upcoming years.

Regional Analysis:

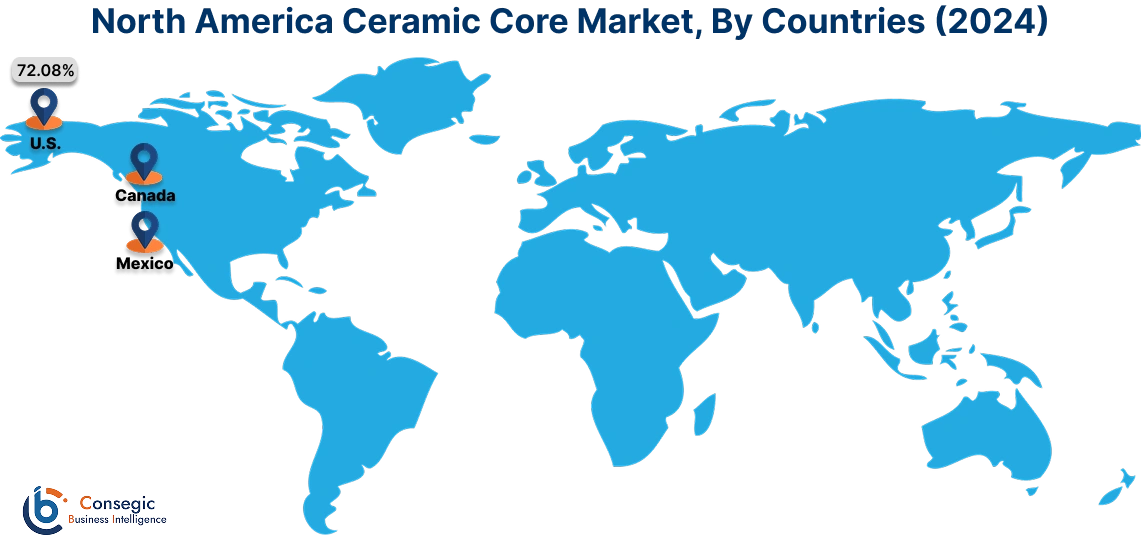

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

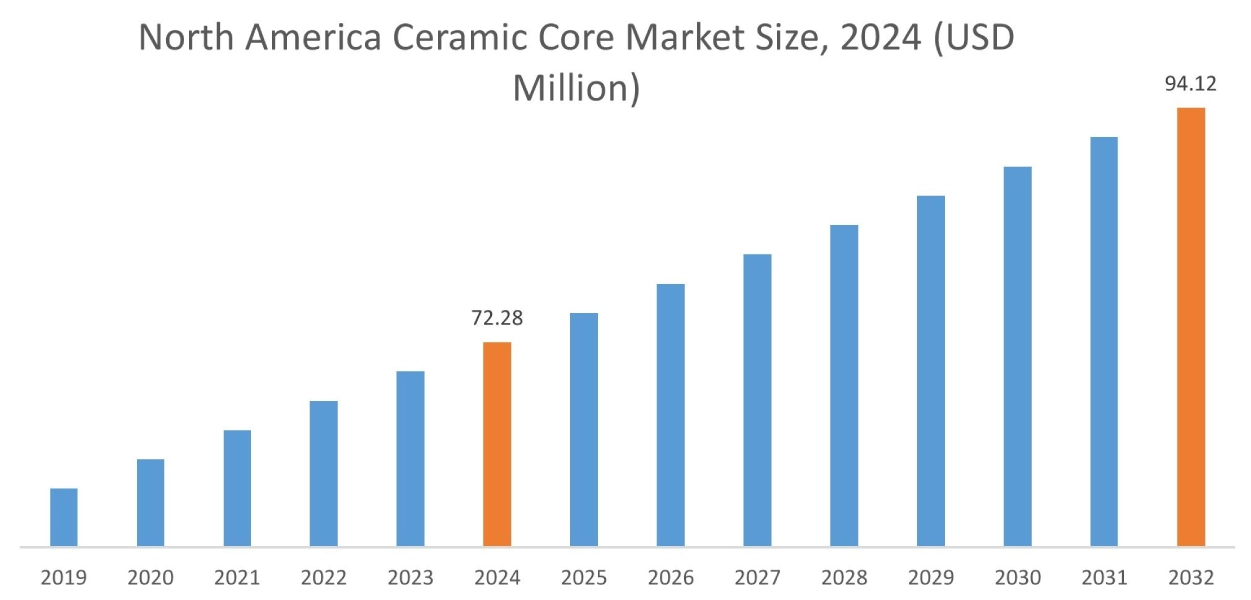

In 2024, North America accounted for the highest market share at 39.78% and was valued at USD 72.28 Million and is expected to reach USD 94.12 Million in 2032. In North America, the U.S. accounted for a market share of 72.08% during the base year of 2024. The North America market demand is significantly defined by the driven by its robust aerospace & defense sector. The United States is a key player in aircraft manufacturing and military spending, consistently demanding high-performance components for jet engines, advanced weaponry, and space applications. Ceramic cores are critical for creating intricate internal cooling passages and complex geometries required in modern turbine blades and other aerospace parts. Continued investment in new aircraft programs, defense modernization, and the pursuit of more fuel-efficient and powerful engines in this region directly translates into sustained and increasing adoption of specialized cores.

- For instance, in 2025 Government of Canada announced new federal funding of USD 1.3 million to enhance access to pilot training in two Saskatchewan cities and to scale up aerospace manufacturing in an urban center.

This adoption in the production of components in aerospace & defense coupled with the strong manufacturing base positions North America as a significant market for these ceramic parts.

In Asia Pacific, the ceramic core industry is experiencing the fastest growth with a CAGR of 5.5% over the forecast period owing to growing emphasis on adoption of electric and hybrid vehicles. Countries like China, Japan, and South Korea are increasingly adopting EVs and manufacturing which is resulting in growing necessity for advanced automotive components. Ceramic cores are becoming crucial for these vehicles, particularly in applications like efficient thermal management systems for battery packs and power electronics, and for creating lightweight yet durable components within electric motors and powertrains. Their ability to withstand high temperatures and provide critical insulation makes them indispensable for improving EV performance, safety, and range, thereby creating substantial opportunities for ceramic core manufacturers in the region.

The Europe market analysis is characterized by the growing adoption of additive manufacturing for cores. European countries are at the forefront of ceramic 3D printing research and commercialization. This technology allows for the creation of highly complex and customized core geometries with greater precision, reduced material waste, and shorter lead times. This innovation is particularly beneficial for European sectors focused on high-performance and customized components, including aerospace, medical, and industrial machinery among others. These factors collectively present a positive impact on the share of European market trends.

The Latin American ceramic core market trend is primarily fueled by the expanding medical device sector. The region is witnessing increased investments in healthcare infrastructure and a rising requirement for advanced medical treatments. As investment casting is a preferred method for producing intricate, high-precision medical components that require biocompatibility and complex internal designs, the need for specialized ceramic cores is growing. This regional focus on enhancing healthcare access and developing domestic medical device manufacturing capabilities is further creating ceramic core market opportunities in the region.

The ceramic core market trend in the Middle East and Africa (MEA) is currently characterized by the region's expanding energy and power sector. Countries in the MEA are heavily investing in modernizing their power generation infrastructure and increasing electricity supply to meet rising industrialization and population growth. This often involves the construction of new thermal power plants, particularly those utilizing advanced industrial gas turbines fueling the need for specialized ceramic cores across the region.

Top Key Players and Market Share Insights:

The Global Ceramic Core Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Ceramic Core market. Key players in the Ceramic Core industry include:

- Morgan Advanced Materials (United Kingdom)

- Imerys (France)

- Avignon Ceramic SAS (France)

- NORITAKE CO., LIMITED (Japan)

- CoorsTek Inc. (U.S.)

- Capital Refractories Limited (United Kingdom)

- HT-Ceram Group (Italy)

- Xiamen Gorgeous New Material Co., Ltd. (China)

- LANIK s.r.o. (Czech Republic)

- Honsin Group (France)

Ceramic Core Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 247.82 Million |

| CAGR (2025-2032) | 4.0% |

| By Type |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Ceramic Core market? +

In 2024, the Ceramic Core market is USD 181.70 Million.

Which is the fastest-growing region in the Ceramic Core market? +

Asia Pacific is the fastest-growing region in the Ceramic Core market.

What specific segmentation details are covered in the Ceramic Core market? +

By Type and End Use segmentation details are covered in the Ceramic Core market.

Who are the major players in the Ceramic Core market? +

Morgan Advanced Materials (United Kingdom), Imerys (France), Capital Refractories Limited (United Kingdom), HT-Ceram Group (Italy) are some of the major players in the market.