Epoxy Resin Market Size:

Epoxy Resin Market size is growing with a CAGR of 5.5% during the forecast period (2025-2032), and the market is projected to be valued at USD 20,047.17 Million by 2032 from USD 13,378.48 Million in 2024.

Epoxy Resin Market Scope & Overview:

Epoxy resins, a class of thermosetting polymers, are known for their strong adhesive properties, resistance to moisture and chemicals, and ability to withstand moderate temperatures. They also exhibit high strength, low shrinkage, and good electrical insulation. These resins offer high tensile, compressive, and impact strengths, making them suitable for structural applications. They adhere well to a variety of substrates, including metals, wood, glass, and concrete. These resins exhibit minimal shrinkage during curing, which helps maintain dimensional stability and prevents cracking. They have excellent dielectric strength and electrical insulation properties, making them ideal for electronic and electrical applications. These resins are resistant to chemicals, solvents, and alkalis. They withstand moderate temperatures and remain stable in demanding environments. They are highly resistant to water, making them suitable for applications where moisture exposure is a concern. Certain formulations also offer UV resistance, preventing degradation and yellowing when exposed to sunlight.

How is AI Transforming the Epoxy Resin Market?

AI-powered systems can predict optimal curing times, thermal resistance, and mechanical strength, leading to more efficient and effective resin production. Furthermore, AI-driven defect detection systems, particularly vision systems, can identify imperfections like voids or air bubbles during manufacturing, ensuring higher product quality. AI algorithms can analyze vast datasets of chemical properties and performance characteristics to design custom epoxy resin formulations tailored to specific customer needs. Also, AI can predict the physical properties of resins, such as flammability, by simulating molecular behavior.

Epoxy Resin Market Dynamics - (DRO) :

Key Drivers:

Rise in the incorporation of epoxy resins in automotive is driving the market growth

Epoxy resins are extensively used in the automotive sector, primarily for their excellent mechanical properties, adhesion to metals, and chemical resistance. They are crucial in various applications, including structural bonding, composite parts, automotive coatings, electrical insulation, and repair and maintenance, enhancing vehicle performance and lifespan. These resins are a key component of cathodic electrodeposition (CED) coatings, which provide superior adhesion to metal and resistance to corrosive agents. These coatings are used as a primer on vehicle bodies and metal parts, preventing rust and extending the vehicle's lifespan. Epoxies are used to bond various materials, including metals and composites, in the vehicle's structure. They create strong, durable joints that are essential for structural integrity.

- For instance, in September 2024, Nagoya University introduced new structural adhesive composed of epoxy resin for automotive sector. The new resin is 22 times higher impact strength than traditional epoxy-based adhesives

Thus, the rise in the incorporation of resins such as epoxy in automotive sector is driving the epoxy resin market growth.

Key Restraints:

Availability of alternative resins is hindering the market growth

Several resin alternatives exist for epoxy resin, with options ranging from traditional polymers like polyester and vinyl ester to more sustainable bio-based resins derived from plants and other biomass sources. The best choice depends on the specific application and desired properties, such as strength, durability, and environmental impact. Moreover, polyester resin offers a cheaper alternative, often used in fiberglass applications such as boats and car bodies among others. Meanwhile, vinyl ester offers good chemical resistance and may be suitable for applications where epoxy might be challenged by harsh chemicals. Thus, the epoxy resin market analysis depicts that the availability of alternative resins is restraining the market growth.

Future Opportunities :

Growing adoption of bio-based epoxy resin is creating potential epoxy resin market opportunities

The growing emphasis on sustainability and the depletion of fossil fuel resources are driving the requirement for bio-based epoxy resins. These eco-friendly alternatives offer a promising solution, as they are derived from renewable sources such as vegetable oils, and biomass amongst others. Bio-based resins exhibit excellent properties, including high thermal stability, superior mechanical strength, and excellent adhesion. These characteristics make them suitable for a wide range of applications, such as coatings, adhesives, and composites. Moreover, their reduced environmental impact and lower carbon footprint align with the increasing global focus on sustainable practices, leading to their adoption. Various manufacturers are introducing novel bio-based resins for various applications.

- For instance, in October 2023, Robnor ResinLab, introduced sustainable innovation with the launch of their new bio-based epoxy resin, PX806C. This resin is used in various electronic components.

Thus, the epoxy resin market analysis shows that the rise in utilization of bio-based epoxy resin is expected to drive the epoxy resin market opportunities during the forecast period.

Epoxy Resin Market Segmental Analysis :

By Type:

Based on type, the market is segmented into aliphatic epoxy resins, bisphenol epoxy resins, novolac epoxy resins, halogenated epoxy resins, and others.

Aliphatic epoxy resins offer excellent heat resistance, UV stability, and high-temperature properties. Bisphenol epoxy resins are the most commonly used epoxy resins. They provide several features including high mechanical strength, good thermal stability, excellent adhesion, and improved chemical resistance among others. Meanwhile, halogenated epoxy resin provides improved chemical resistance and fire-resistant properties among others.

Trends in the Type:

- Aliphatic epoxy resins are gaining popularity due to their superior weatherability, UV resistance, and color stability is driving the epoxy resin market size.

- Increasing adoption of halogenated epoxy resins, particularly those containing bromine, due to its excellent flame-retardant properties.

The bisphenol epoxy resin segment accounted for the largest epoxy resin market share in 2024 and it is expected to grow at the fastest CAGR over the forecast period.

Bisphenol epoxy resins, particularly Bisphenol A (BPA) and Bisphenol F (BPF) epoxy resins, are widely used in various applications due to their exceptional properties. These resins offer high strength, excellent adhesion, robust chemical resistance, and good thermal stability. They are known for their ability to bond well with various materials and resist degradation under harsh conditions. Bisphenol epoxy resins are known for their high tensile and flexural strength, making them suitable for load-bearing applications.

- For instance, in 2023, Nan Ya Plastics Corporation introduced a cutting-edge Bisphenol A (BPA) production line in Ningbo, China. This new facility is expected to significantly boost the company's production capacity and meet the growing global requirement for BPA, a crucial raw material in the production of various plastics and resins such as epoxy.

As per the analysis, the aforementioned factors are driving the epoxy resin market growth.

By Application:

Based on application, the market is categorized into electronic encapsulation, paints & coatings, wind turbines, adhesives, composites, and others.

Epoxy is primarily used for encapsulating electronic components, including circuit boards, connectors, sensors, and others. Moreover, epoxy is widely used in paints and coatings, due to its durable finish, strong adhesion, and resistance to UV, corrosion, and chemicals. Epoxy offers high bonding strength, which makes it ideal for use in structural adhesives for bonding a variety of materials. Additionally, epoxy is also used in composites, due to its strong adhesive properties, chemical resistance, and ability to withstand high temperatures.

Trends in the Application:

- Rising adoption of epoxy resins in encapsulating components and protecting them from environmental factors like moisture, thermal shock, and mechanical stress is boosting the epoxy resin market size.

- Increasing trend in adoption of epoxy resins are essential for protecting wind turbine blades from environmental factors like UV radiation, moisture, and extreme temperatures.

The paints & coatings segment accounted for the largest market share in 2024.

Epoxy resins are used in paints and coatings applications due to their excellent adhesion, durability, chemical resistance, and mechanical properties. They are favored for creating protective coatings in various industrial sectors, particularly for metal substrates such as steel structures, pipelines, and storage tanks. Epoxy paints also enhance the appearance, durability, and protection of consumer products like flooring, furniture, and decorative items.

- For instance, in 2024, PPG introduced PPG STEELGUARD 951, a novel intumescent fire protection coating that is prepared using epoxy resins. This innovative solution is designed to safeguard advanced manufacturing facilities, including semiconductor plants, electric vehicle battery facilities, data centers, and other critical infrastructure.

Thus, the analysis shows that the rising trend in adoption of these resins in paints and coatings applications is driving the epoxy resin market demand.

The composites segment is expected to register fastest CAGR over the forecast period.

Epoxy resins are used in composite materials due to their strong adhesive properties, chemical resistance, and ability to withstand high temperatures. They are particularly favored in applications requiring lightweight yet durable structures, such as in aerospace and automotive industries.

Moreover, these resins exhibit strong bonding to various substrates, including fibers and other materials, making them effective in composite structures. They are resistant to a wide range of chemicals, solvents, and moisture, which is crucial for applications in harsh environments. Thus, based on the analysis, the aforementioned factors are boosting the epoxy resin market trends.

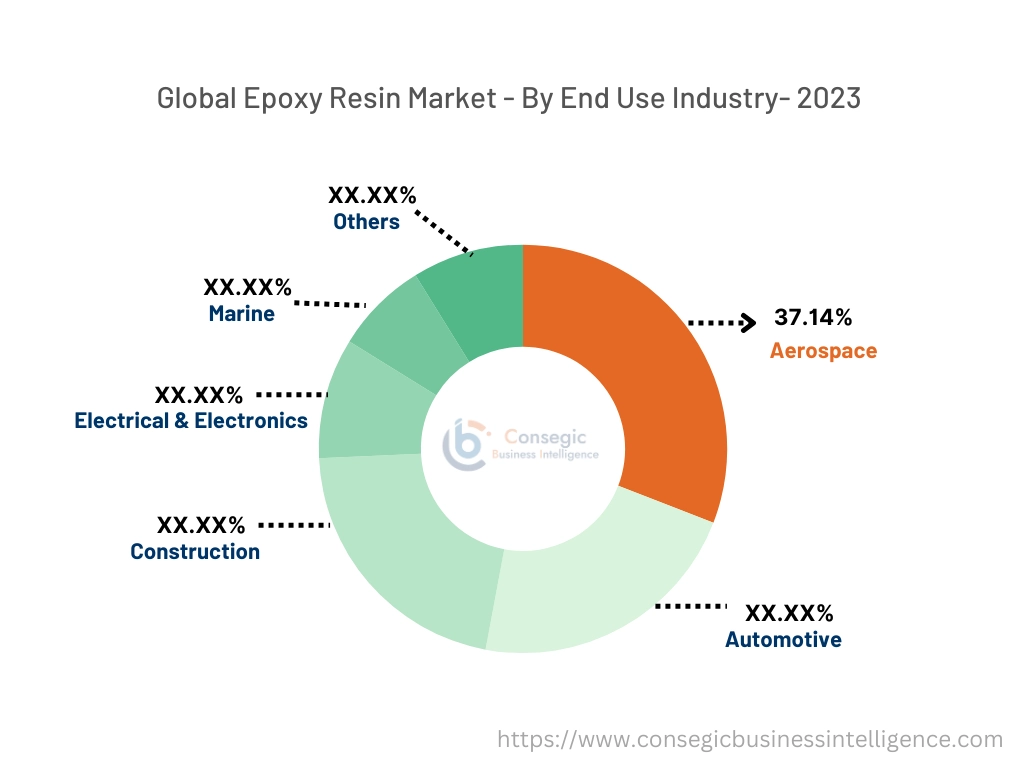

By End User Industry:

Based on the end-user industry, the market is categorized into aerospace, automotive, construction, electrical & electronics, marine, and others.

Epoxy is primarily used in several industries including aerospace, automotive, construction, electrical & electronics, marine, and other industries, for applications involving paints & coatings, adhesives, sealants, composites, and others. Moreover, epoxy resin properties including high strength, durability, excellent adhesion, and improved resistance to UV, chemical, and corrosion, makes it ideal for utilization in aforementioned industries.

Trends in the End-User Industry:

- Rising adoption of resins for producing lightweight, high-strength composite materials used in aircraft structures.

- Increasing trend in utilization of epoxy coatings to protect marine vessels from corrosion caused by saltwater exposure is boosting the epoxy resin market demand.

The electrical & electronics segment accounted for the largest market share of 37.14% in the year 2024.

Epoxy resins are widely used in electrical and electronics applications due to their excellent electrical insulation properties, ability to protect components from environmental factors, and versatility in various applications like encapsulation and potting among others. Moreover, they offer robust protection against moisture, dust, and mechanical damage, ensuring the reliability and longevity of electronic devices. These resins provide excellent electrical insulation, preventing short circuits and ensuring safe and efficient operation of electrical devices.

- For instance, in 2023, Dongying Yi Rui Zengnew Material Technology Co., LTD. recently approved a significant project in Dongying Economic and Technological Development Zone, Shandong Province. This project aims to establish a new material production facility with an annual capacity of 200,000 tons for electronic-grade epoxy resin.

Thus, the aforementioned factors are driving the epoxy resin market trends.

The construction segment is expected to grow at the fastest CAGR over the forecast period.

Epoxy resins are widely used in construction sector due to their strong adhesive properties, durability, and versatility. They are utilized in various applications, including flooring, concrete repair, waterproofing, and anchoring. These resins also enhance concrete strength and structural integrity, minimize shrinkage and cracking, and provide excellent adhesion to various surfaces.

Additionally, these resins are also used to create durable and aesthetically pleasing floors, including terrazzo, aggregate, and chip flooring. Thus, the aforementioned factors are driving the epoxy resin market expansion.

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

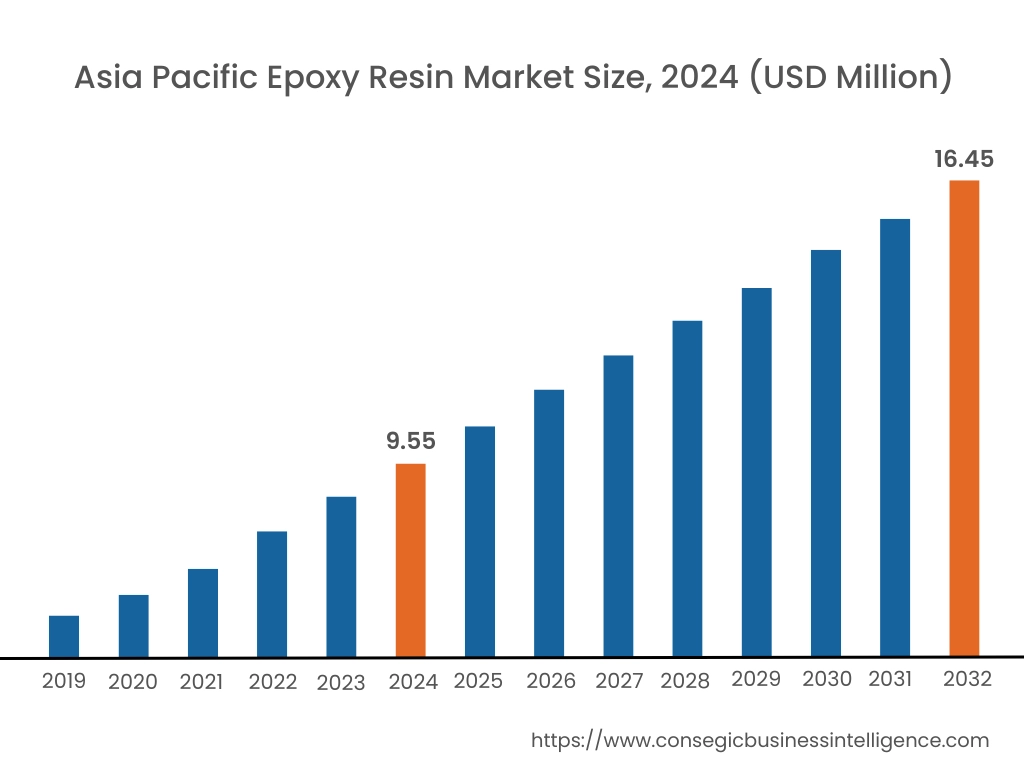

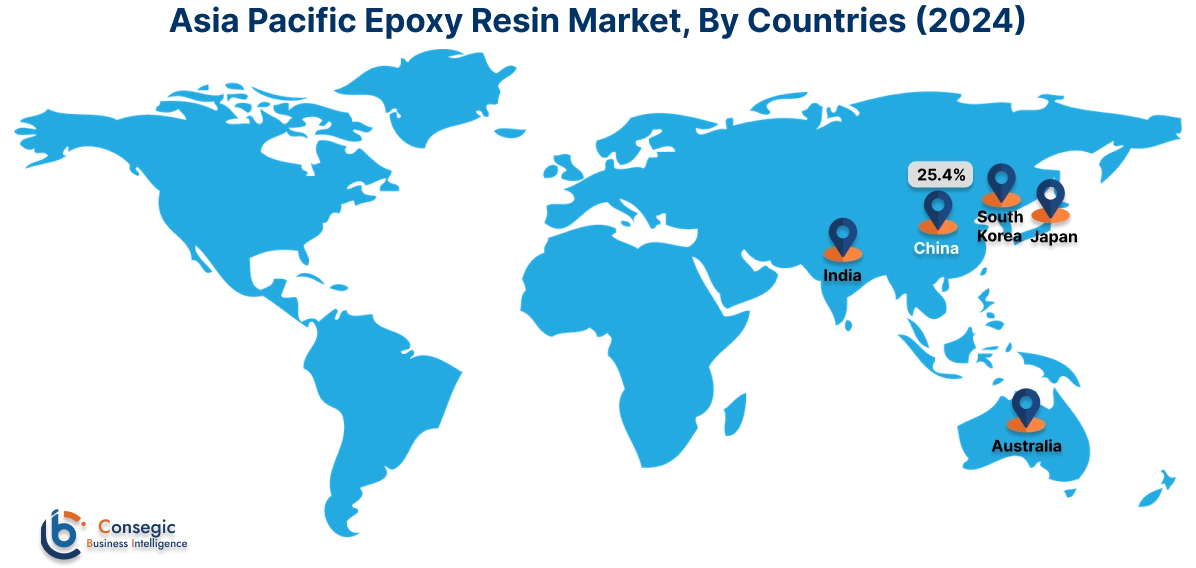

In 2024, Asia Pacific accounted for the highest epoxy resin market share at 33.0% and was valued at USD 4,412.51 Million and is expected to reach USD 6,519.34 Million in 2032. In Asia Pacific, China accounted for the highest market share of 25.4% during the base year of 2024. The Asia-Pacific region is a rapidly growing market for epoxy resins, driven by rapid industrialization and urbanization. The region's focus on infrastructure development and renewable energy is also driving the requirement for high-performance resins.

- For instance, in 2024, Aditya Birla Group's Advanced Materials business announced a significant investment to expand its production capacity at its Vilayat, Gujarat, India facility. This development will increase the production capacity by approximately 125,000 tons per annum (KTPA) for both standard and specialty epoxy products, as well as curing agents.

The North American market for Epoxy resin is experiencing the fastest growth with a CAGR of 6.1% over the forecast period. The epoxy resin industry is driven by robust requirements from diverse industries. As per the analysis, the region's strong manufacturing base, particularly in automotive, aerospace, and construction, fuels significant consumption of these resins.

- For instance, in 2024, SOMAR, a manufacturer of specialty chemicals, announced a significant investment of USD 2.5 million to establish a new epoxy resin manufacturing plant in West Virginia, U.S. This strategic move aims to meet the growing demand for high-quality resins in the North American region.

In Europe, the growth of epoxy resin industry is driven by factors such as growing electronics, marine, and energy sectors, combined with the region's technological advancements and sustainable initiatives are boosting the market. Additionally, the rise in the use of bio-based solutions is driving epoxy resin market expansion in the European region. The Latin America, Middle East and Africa regions are witnessing a growing demand for epoxy resins, driven by factors such as rapid urbanization, infrastructure development, and industrial growth among others.

Top Key Players & Market Share Insights:

The epoxy resin industry is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global epoxy resin market. Key players in the global epoxy resin market include-

- China Petrochemical Corporation(Sinopec) (China)

- Solvay(Belgium)

- Kukdo Chemical Co., Ltd. (Korea)

- Olin Corporation (United States)

- Sika AG (Switzerland)

- Aditya Birla Management Corp. Pvt. Ltd.( India)

- Nan Ya Plastics Corporation (Taiwan)

- Mitsubishi Chemical Group Corporation. (Japan)

- NAGASE & Co., Ltd. (Japan)

- Kolon Industries, Inc (South Korea)

Recent Industry Developments :

Investments:

- In 2024, DCM Shriram, signed an agreement to invest over the next few years in order to establish an epoxy resin manufacturing plant in Jhagadia, Gujarat, India. This aims to marks the company's entry into the advanced materials sector.

Epoxy Resin Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 20,047.17 Million |

| CAGR (2024-2031) | 5.5% |

| By Type |

|

| By Application |

|

| By End-User Industry |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Epoxy Resin Market? +

In 2024, the Epoxy Resin Market is USD 13,378.48 Million.

Which is the fastest-growing region in the Epoxy Resin Market? +

North America is the fastest-growing region in the Epoxy Resin Market.

What specific segmentation details are covered in the Epoxy Resin Market? +

Type, Application, and End-Use Industry segmentation details are covered in the Epoxy Resin Market

Who are the major players in the Epoxy Resin Market? +

China Petrochemical Corporation (Sinopec) (China), Solvay (Belgium), Aditya Birla Management Corp. Pvt. Ltd.( India), NAGASE & Co., Ltd. (Japan), Kolon Industries, Inc (South Korea), Kukdo Chemical Co., Ltd. (Korea), Olin Corporation (United States), Sika AG (Switzerland), Nan Ya Plastics Corporation (Taiwan), Mitsubishi Chemical Group Corporation. (Japan).