Gas Separation Membrane Market Size:

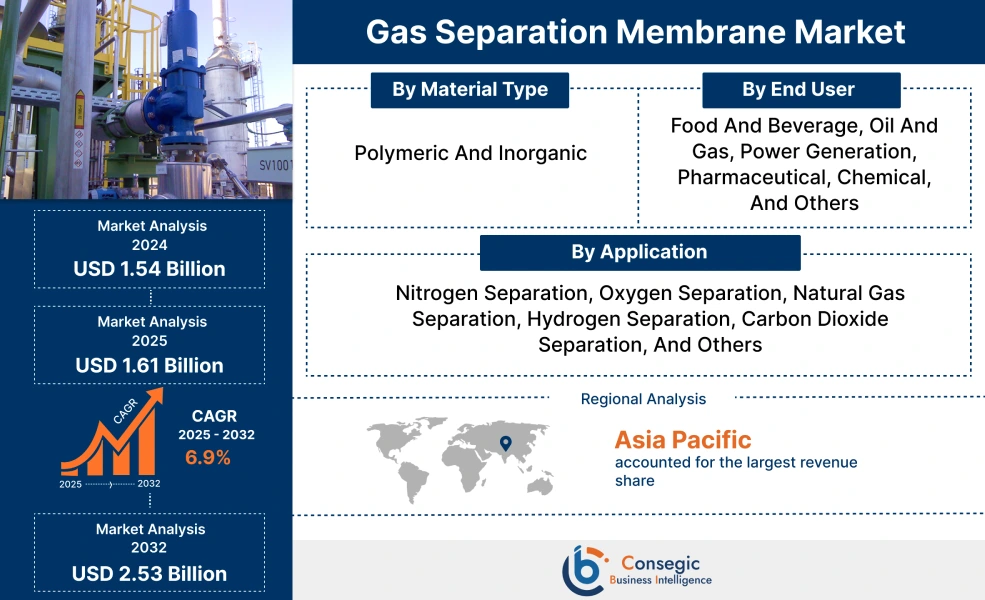

Gas Separation Membrane Market size is estimated to reach over USD 2.53 Billion by 2032 from a value of USD 1.54 Billion in 2024 and is projected to grow by USD 1.61 Billion in 2025, growing at a CAGR of 6.9% from 2025 to 2032.

Gas Separation Membrane Market Scope & Overview:

Gas separation membrane refers to membranes that are used for the separation of gases to allow certain gases to pass through. Gas filtration membranes use selective permeation to filter out unwanted gases or specific contamination from gases. Further, gas filtration membranes are used in various industries including chemical and food & beverage for environmentally friendly separation of gases. Additionally, manufacturers are increasingly investing in designing membranes to filter gases with high specific permeability. Moreover, companies have witnessed growing need for membrane cartridges with high selectivity and high specific membrane area which has driven the market.

How is AI Impacting the Gas Separation Membrane Market?

AI is significantly impacting the gas separation membrane market by enhancing performance, optimizing processes, and enabling data-driven insights. AI algorithms, especially machine learning, have the ability to model and predict membrane performance under various conditions, identifying optimal operating parameters for factors such as pressure, temperature, and flow rate.

Gas Separation Membrane Market Dynamics - (DRO) :

Key Drivers:

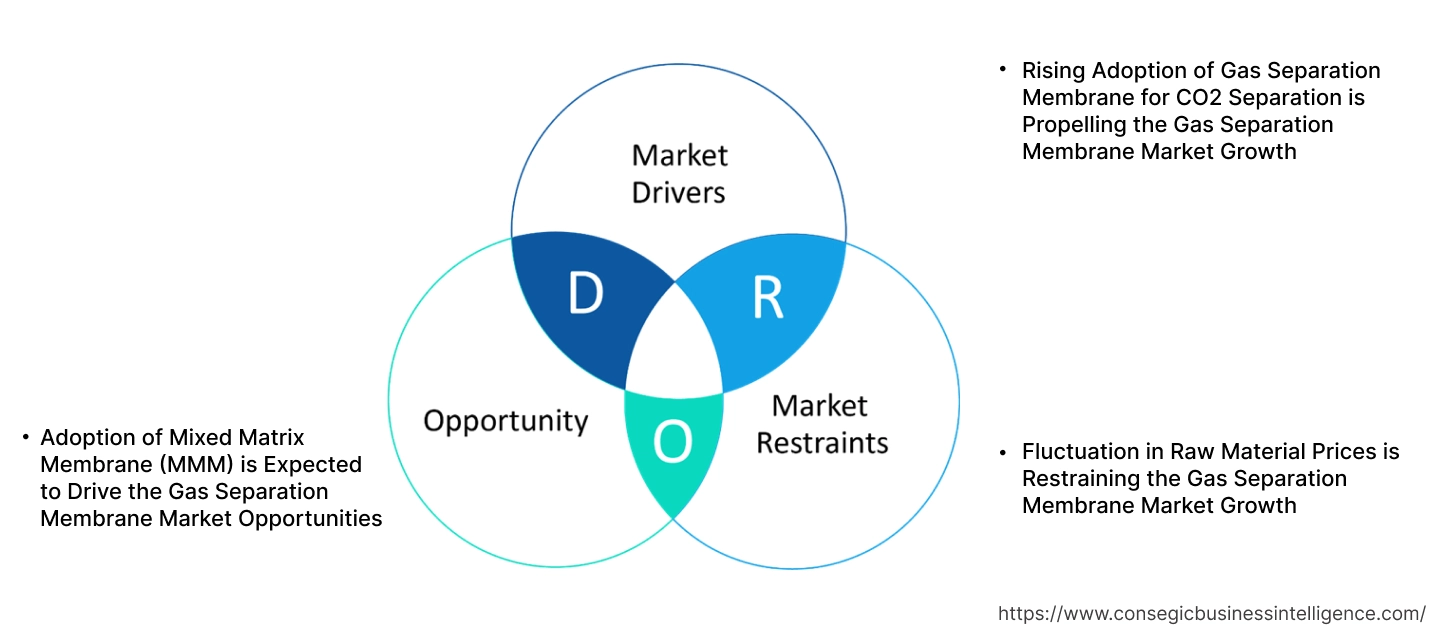

Rising Adoption of Gas Separation Membrane for CO2 Separation is Propelling the Gas Separation Membrane Market Growth

Rising awareness among industries to minimize CO2 footprint using membrane solutions for CO2 capture and recovery has driven the market expansion. Manufacturers have started offering membranes that provide efficient and cost-effective solutions for separating carbon dioxide from gases. Moreover, membrane based CO2 capture processes offer capturing and removal of CO2 in power generation and industries that utilize cement.

- For instance, Borsig offers advanced CO2 gas filtration membranes that provide high selectivity for CO2 separation. The membrane can be used to remove CO2 from combustion flue gas in power generation.

Hence, the growing use of gas filtration membrane to separate CO2 is driving the gas separation membrane market size.

Key Restraints:

Fluctuation in Raw Material Prices is Restraining the Gas Separation Membrane Market Growth

Gas filtration membranes use various raw materials within the membranes including polymers and ceramic. Polymer prices are prone to fluctuations due to supply chain disruptions as a result of production shutdowns or economic fluctuations. Further, cellulose, a key material used in membranes, is made up of wood pulp which can also be subject to price and supply fluctuations hindering the market growth. Thus, fluctuation in prices of key raw materials used in the production of gas filtration membranes act as a restraint to the gas separation membrane market expansion.

Future Opportunities :

Adoption of Mixed Matrix Membrane (MMM) is Expected to Drive the Gas Separation Membrane Market Opportunities

Mixed Matrix Membrane (MMM) combines both polymeric and inorganic materials for use in gas filtration membranes. Mixed Matrix Membranes show a color change when they are exposed to vapors of different amines which can be useful for detection and filtering of gases.

- For instance, according to a study from Institute of Nano Science and Technology, an autonomous institute of Department of Science and Technology, MMM can show a remarkable color change when it is expose to vapors of different amines which can be useful for gas leakage detection and separation.

Thus, the rising technological advancements associated with mixed matrix membrane are projected to drive the gas separation membrane market opportunities during the forecast period.

Gas Separation Membrane Market Segmental Analysis :

By Material Type:

Based on material type, the market is segmented into polymeric and inorganic.

Trends in the material type:

- Increasing adoption of polymeric materials for rapid passage of a single gas is driving the gas separation membrane market share.

- Rising utilization of inorganic materials due to narrow pore size distribution is driving the gas separation membrane market trends.

Polymeric accounted for the largest revenue share in the year 2024.

- Gas filtration membranes have seen a rising adoption of polyimide hollow fibre membranes for use in generating biomethane by separating CO2.

- Various polymers including polyamides and polysulfone are used in gas filtration membranes due to their cost-efficiency.

- Additionally, manufacturers today offer gas filtration membrane materials that are cellulose based with medium viscosity, driving the market.

- For instance, Eastman offers membrane material M210 with medium viscosity and medium molecular weight cellulose diacetate for use in natural gas filtration.

- According to the market analysis, the rising advancements related to polymeric due to integration of cost-efficient polyimide fibre membranes and cellulose based membranes are driving the gas separation membrane market trends.

Inorganic is anticipated to register the fastest CAGR during the forecast period.

- Inorganic materials for gas filtration membranes include ceramic, metal and metal oxide among others.

- Moreover, manufacturers today offer ceramic nanofiltration membranes with chemical and thermal stability which can be useful for the petroleum sector.

- For instance, JIUWU HI-TECH offers ceramic nanofiltration membranes for the petroleum and chemical sector due to their chemical and thermal stability. The membranes use nanofiltration technology along with ceramics to offer high mechanical strength and acid and alkali resistance.

- Thus, the rising trend in the utilization of inorganic membranes, specifically ceramic membranes is propelling the gas separation membrane market demand during the forecast period.

By Application:

Based on the application, the market is segmented into nitrogen separation, oxygen separation, natural gas separation, hydrogen separation, carbon dioxide separation, and others.

Trends in the application:

- Rising trend towards adoption of gas filtration membranes for natural gas separation to dehydrate natural gas stream for re-injection is driving the global gas separation membrane market.

- Quick start up time of the separation membranes to produce nitrogen purity instantly has resulted in the growth of the nitrogen segment.

Natural gas separation accounted for the largest revenue share in the year 2024.

- Membrane products for natural gas are used to simplify the gas purification process by removing multiple contaminants in natural gas in fewer steps.

- Moreover, gas separation filtration systems have started integrating small diameter porous tubes made of polyimide for offshore separation applications where space is limited.

- Additionally, manufacturers have started offering membranes with smaller footprint and high pressure operating capability for use in natural gas treatment.

- For instance, Air Liquide offers membrane modules that are compact and can operate with high pressure, ranging from 1000-1500 psig differential pressure.

- According to the analysis, increasing advancements associated with natural gas filtration membranes due to effective removal of multiple contaminants, high pressure operating capability and compact design of the membrane products are driving the gas separation membrane market expansion.

Nitrogen separation is anticipated to register the fastest CAGR during the forecast period.

- Membranes for nitrogen separation are utilized primarily for removing oxygen from products.

- Many manufacturers are increasingly focusing on reducing CO2 emissions through the nitrogen gas filtration membranes by reducing energy consumption.

- For instance, Parker Hannifin offers nitrogen separation membrane called HiFluxx that can provide nitrogen gas of 95% to 99.5% purity. The membrane does not require a heater to open the polymer membrane structure which reduces the energy consumption.

- According to the market analysis, the increasing advancements related to nitrogen separation due to high purity of nitrogen and reduced energy consumption are anticipated to boost the overall market trends during the forecast period.

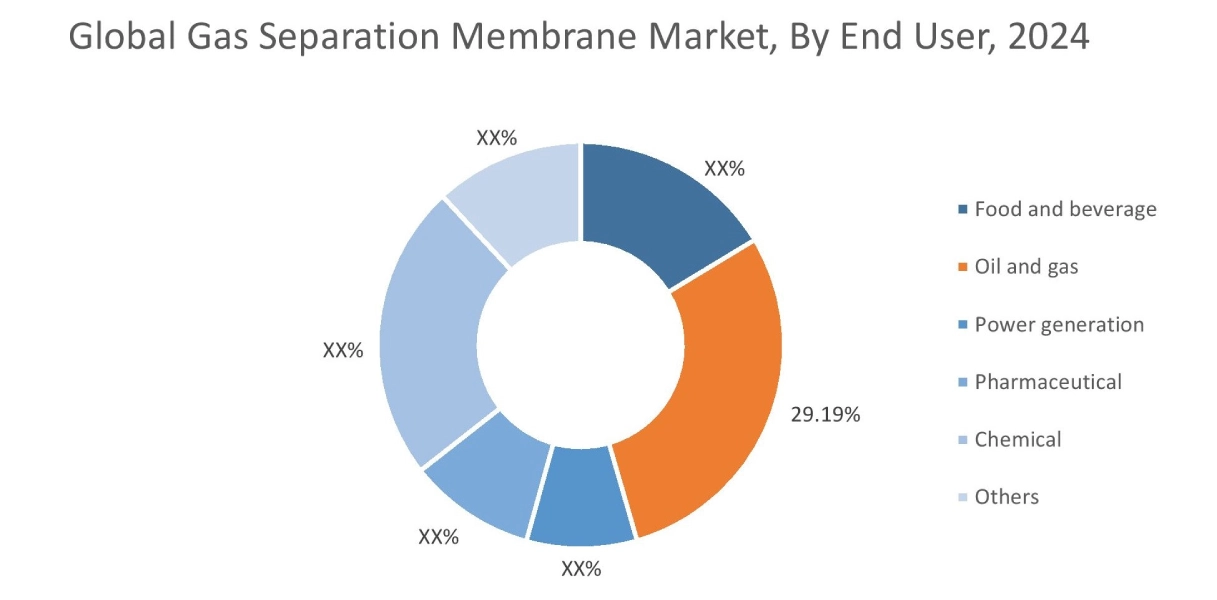

By End User:

Based on the end user, the market is segmented into food and beverage, oil and gas, power generation, pharmaceutical, chemical, and others.

Trends in the end user:

- Increasing adoption of large diameter membranes that are highly selective for acid gases is driving the oil and gas segment.

- Growing investments in membranes that can efficiently separate air and nitrogen are driving the food and beverage segment.

Oil and gas accounted for the largest revenue share of 29.19% in the year 2024.

- Oil and gas facilities use gas filtration membranes that are robust and operationally simple for both onshore and offshore applications.

- Moreover, the increasing adoption of gas filtration membrane for removal of carbon dioxide and hydrogen sulfide from natural gas streams is driving the segment.

- Additionally, companies have started integrating two membranes to recover LPG and hydrogen from fuel gas.

- For instance, Membrane Technology and Research offers VaporSep unit for LPG recovery from refinery streams. The unit uses two membranes for permeating hydrogen and LPG.

- Therefore, the increasing demand for gas filtration membranes used in removal of hydrogen and CO2 in oil and gas is driving the gas separation membrane market size.

Food and beverage is anticipated to register the fastest CAGR during the forecast period.

- Food and beverage sector requires highly pure nitrogen for the packaging of products to preserve quality which in turn drives the market.

- Many companies in alcohol and beverage sector use gas filtration membranes to preserve high purity nitrogen while removing other gases to prevent the spoilage of the drinks, resulting in growth.

- For instance, Evonik offers the SEPURAN N2 membranes to reduce atmospheric oxygen and preserve nitrogen purity of up to 99.5%, making the membranes ideal for food and beverage sector.

- Thus, according to the gas separation membrane market analysis, the rising adoption of membranes during packaging of products in food and beverage industry is propelling the market during the forecast period.

Regional Analysis:

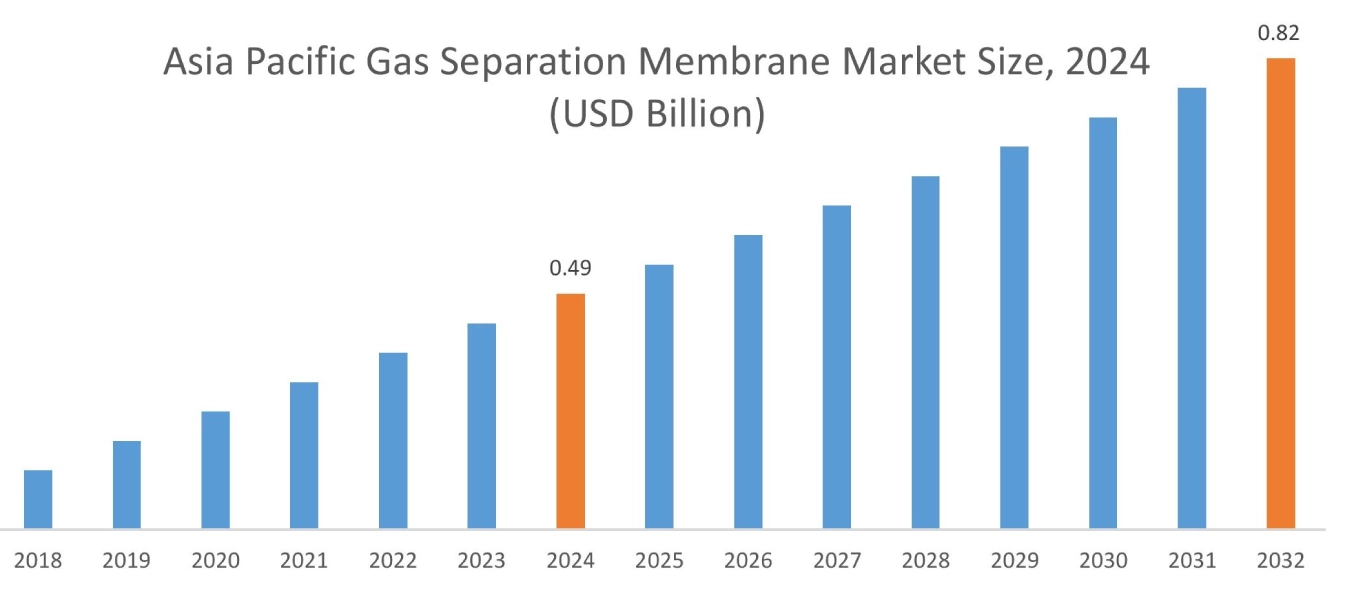

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

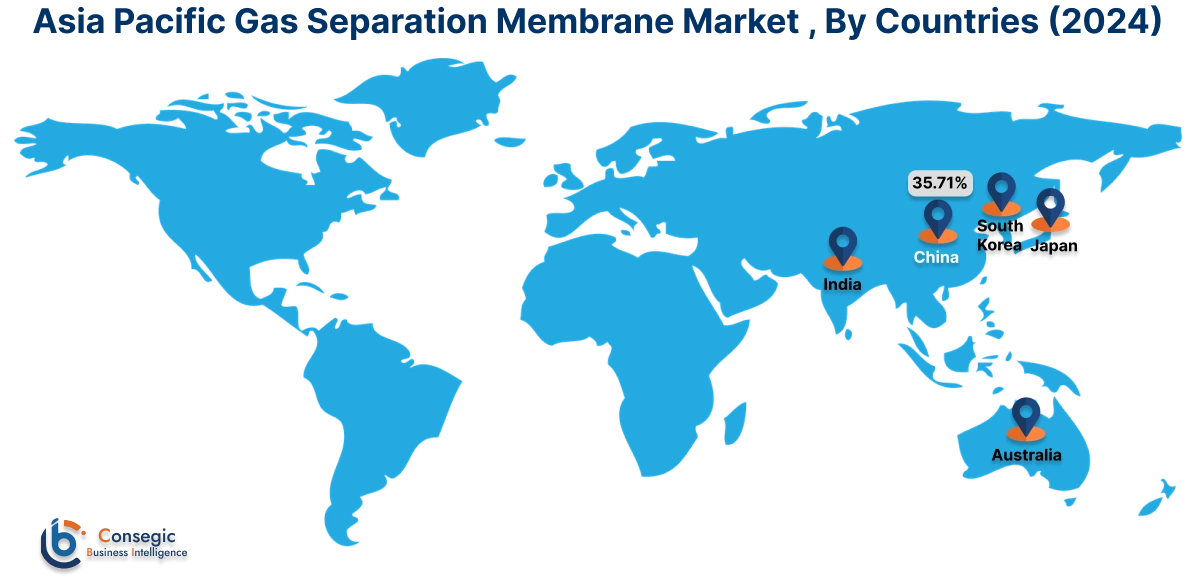

Asia Pacific region was valued at 0.49 Billion in 2024. Moreover, it is projected to grow by 0.51 Billion in 2025 and reach over 0.82 Billion by 2032. Out of this, China accounted for the maximum revenue share of 35.71%. As per the gas separation membrane market analysis, the growth in adoption of gas filtration membranes in the Asia-Pacific region is primarily driven by the rising adoption of separation membranes for use in power generation and petrochemical industries.

- For instance, according to the ministry of power, the state, central, and private sector combined have power generation capacity of approximately 4,17,668 MW in India. The power generation sector uses natural gas that is filtered using gas filtration membranes to generate electricity which is expected to boost the overall gas separation membrane industry.

North America is estimated to reach over USD 0.74 Billion by 2032 from a value of USD 0.45 Billion in 2024 and is projected to grow by USD 0.47 Billion in 2025. In North America, the growth of gas separation membrane industry is driven by the growing investments in the food and beverage sector. Moreover, the increasing adoption of polymer membranes to separate high-pressure hydrogen has resulted in the rise of gas separation membrane market share.

- For instance, Honeywell offers PolySep Membrane Systems for high pressure hydrogen separations. The company offers hydrogen membranes that are cost effective for separation where the pressure can be higher than 1000 psig. The increasing adoption of polymer-based membranes for hydrogen separation is expected to drive the overall market.

Additionally, the regional analysis depicts that the growing adoption of gas filtration membranes in chemicals segment is driving the gas separation membrane market demand in Europe. Furthermore, as per the market analysis, the market demand in Latin America is expected to grow at a considerable rate due to rising adoption of gas filtration membranes for use in the packaging of pharmaceuticals. Middle East and African regions are expected to grow at a considerable rate due to factors such as growing demand for gas filtration membranes in filtering oxygen and growing investments in food and beverage sector among others.

Top Key Players and Market Share Insights:

The global gas separation membrane market is highly competitive with major players providing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the gas separation membrane market. Key players in the gas separation membrane industry include-

- Fujifilm Corporation (Japan)

- UBE Corporation (Japan)

- Honeywell International Inc. (U.S.)

- Evonik Industries AG (Germany)

- SLB (U.S.)

- Air Liquide (France)

- Generon (U.S.)

- JIUWU HI-TECH Membrane Technology (China)

- Parker Hannifin Corp (U.S.)

- Membrane Technology and Research Inc. (U.S.)

Recent Industry Developments :

Partnership and Collaboration:

- In January 2025, Arkema and OOYOO Ltd. announced their partnership to develop gas separation membranes for the purpose of carbon capture. The partnership aims to accelerate performance improvements and cost reduction of OOYOO’s gas separation membranes through new high performance materials developed by Arkema.

Market Expansion:

- In December 2024, Toray Industries Inc. announced that it will install a pilot facility for all of its CO2 separation membranes at Shiga Plant. The company aims to use the new facility to establish mass production technology for CO2 separation membranes.

Gas Separation Membrane Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 2.53 Billion |

| CAGR (2025-2032) | 6.9% |

| By Material Type |

|

| By Application |

|

| By End User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the gas separation membrane market? +

The gas separation membrane market is estimated to reach over USD 2.53 Billion by 2032 from a value of USD 1.54 Billion in 2024 and is projected to grow by USD 1.61 Billion in 2025, growing at a CAGR of 6.9% from 2025 to 2032.

Which is the fastest-growing region in the gas separation membrane market? +

Asia-Pacific region is experiencing the most rapid growth in the gas separation membrane market.

What specific segmentation details are covered in the gas separation membrane market report? +

The gas separation membrane market report includes material type, application, end user, and region.

Who are the major players in the gas separation membrane market? +

The key participants in the gas separation membrane market are Fujifilm Corporation (Japan), Air Liquide (France), Generon (U.S.), JIUWU HI-TECH Membrane Technology (China), Parker Hannifin Corp (U.S.), Evonik Industries AG (Germany), UBE Corporation (Japan), Honeywell International Inc. (U.S.), SLB (U.S.), Membrane Technology and Research Inc. (U.S.), and Others.