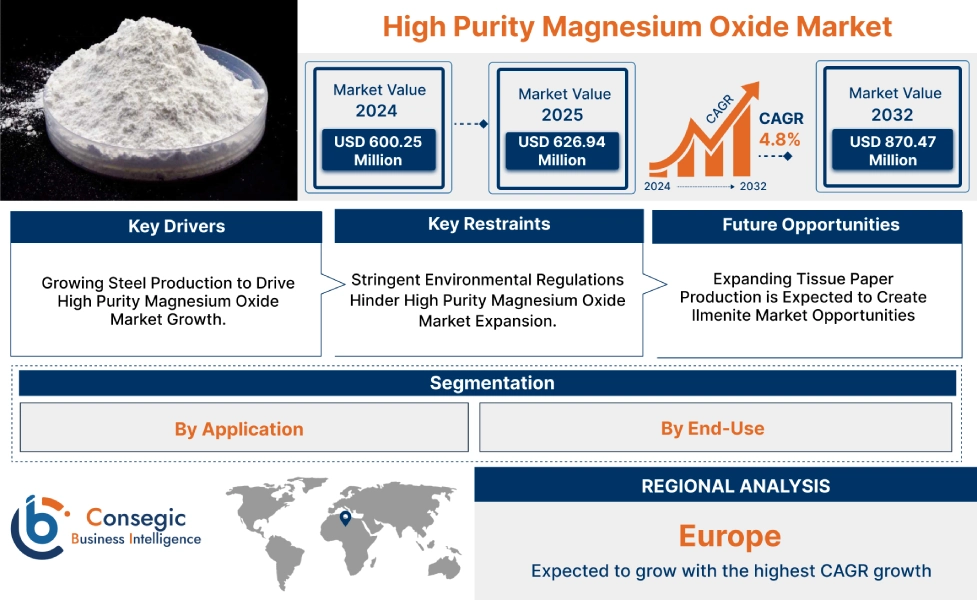

High Purity Magnesium Oxide Market Size:

The High Purity Magnesium Oxide Market size is growing with a CAGR of 4.8% during the forecast period (2025-2032), and the market is projected to be valued at USD 870.47 Million by 2032 from USD 600.25 Million in 2024. Additionally, the market value for 2025 is attributed to USD 626.94 Million.

High Purity Magnesium Oxide Market Scope & Overview:

High purity magnesium oxide (HP MgO) is an organic compound with a purity exceeding 99.5%. It occurs as a white, hygroscopic solid compound found as a natural mineral periclase. This high purity is crucial for most demanding applications in refractories, pharmaceuticals, food & beverages, and electronics, among others. HP MgO is a critical component in the manufacturing of refractory materials, which are essential for high-temperature industrial applications within the steel, cement, and glass sectors. Its unique characteristics, such as high melting point, excellent electrical insulation, and chemical stability, make it indispensable in several sectors. Overall, the market for high purity MgO is a specialized segment within the broader magnesium oxide market, driven by the demand for materials with superior properties and minimal impurities across various high-tech and sensitive applications.

High Purity Magnesium Oxide Market Scope & Overview:

AI is significantly impacting the high-purity magnesium oxide market by driving demand and optimizing production. The increasing need for high-specification materials in advanced electronics, clean energy, and pharmaceuticals, often fueled by AI-driven innovations, boosts demand for high-purity MgO. AI is also being integrated into the manufacturing process, improving quality control, purity levels, and production efficiency through intelligent automation and data analytics. This includes optimizing calcination processes and ensuring consistent batch-to-batch quality. Furthermore, AI-powered demand forecasting helps producers better manage supply chains, ensuring timely delivery for critical applications.

High Purity Magnesium Oxide Market Dynamics - (DRO) :

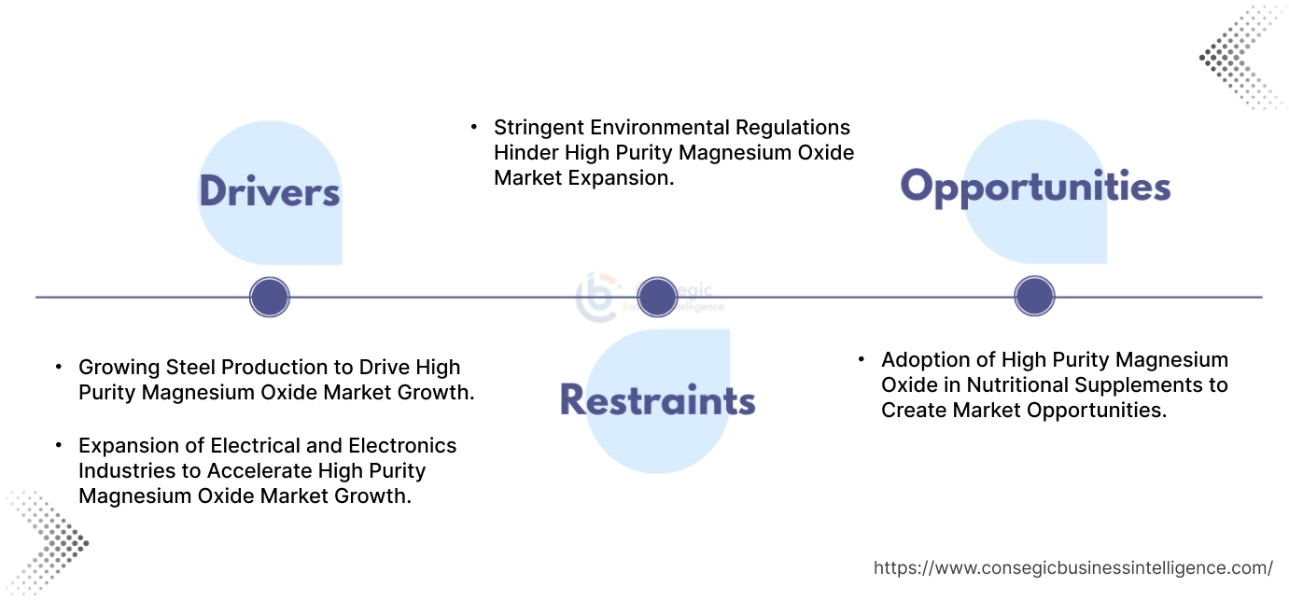

Key Drivers:

Growing Steel Production to Drive High Purity Magnesium Oxide Market Growth.

The high-temperature processes involved in steel manufacturing necessitate the use of robust refractory materials to line furnaces, converters, ladles, and other critical equipment. Steel production employs magnesium oxide with high purity, particularly the dead-burned form and fused magnesia as a vital component in refractory linings for furnaces and converters. Refractories use the inherent ability of the compound to withstand high furnace temperatures. Additionally, it also delivers the ability to withstand rapid temperature changes and resistance to reaction with molten steel and slag. As global demand for higher quality, more specialized steel products accelerate, the sector's requirement for refractory materials surges, directly impacting market demand.

- For instance, according to World Steel Association AISBL, steel production across the globe including 71 countries increased by 5.6% from 2023 reaching 5 million tons in 2024.

Thus, due to the above-mentioned factors, the market for the compound in steel production is witnessing significant growth.

Expansion of Electrical and Electronics Industries to Accelerate High Purity Magnesium Oxide Market Growth.

The properties of high purity MgO, which offer a combination of excellent insulation properties and thermal conductivity, are used in various electronic components, insulators, substrates, and electrical heating elements among others. In addition to this, the compound also serves as the insulating filler material in tubular heating elements for consumer appliances and industrial. As the world is experiencing the continued demand for consumer electronics, the requirement for HP MgO is rising.

- For instance, the total mobile production volume in China reached 1.67 billion units, representing a 7.8% increase. Of this total, smartphones experienced an 8.2% year-over-year increase.

Thus, as per the market analysis, the increasing requirement for the compound in electronic components is contributing to market growth.

Key Restraints:

Stringent Environmental Regulations Hinder High Purity Magnesium Oxide Market Expansion.

The mining of magnesite used in the development of magnesium oxide is often associated with substantial soil and water contamination, alongside the generation of waste and air pollution that requires rigorous regulatory oversight. These regulations are important for environmental preservation which lead to an increase in production costs. This acts as a financial hurdle for key players operating in the market. Furthermore, the complex nature of waste disposal and processing needs significant capital. Consequently, compliance with these stringent standards leads to supply chain disruptions, as mining and processing operations face potential closures or restrictions due to non-compliance. The global focus on sustainability is further amplifying the regulatory pressure, leading the key players to adopt more environmentally responsible practices. Hence, as per analysis, the aforementioned factors are restraining high purity magnesium oxide market expansion.

Future Opportunities :

Adoption of High Purity Magnesium Oxide in Nutritional Supplements to Create Market Opportunities.

The role of magnesium oxide in nutritional supplements, especially those with high purity, is one of the major factors creating new high purity magnesium oxide market opportunities. Consumers are increasingly proactive about preventive healthcare. This results in the higher consumption of supplements where magnesium plays a vital role in numerous bodily functions. This growing awareness coupled with a requirement for pure, high-quality ingredients influences manufacturers to source HP MgO to meet stringent regulatory standards.

For instance,

- In 2025, Willows Ingredients introduced the Mg Neezium Series as a new line of premium magnesium solutions. This tailored suite of high-quality magnesium oxide ingredients has been developed specifically to address the increasing needs of the health and wellness market.

Consequently, this creates the potential for manufacturers to capitalize on this by developing specialized grades, further creating high purity magnesium oxide market demand.

High Purity Magnesium Oxide Market Segmental Analysis :

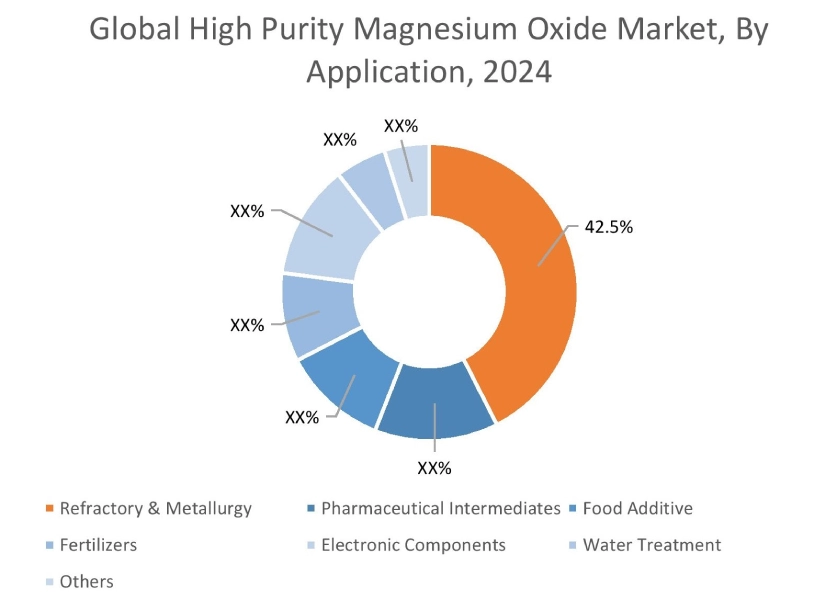

By Application:

Based on application, the market is categorized into refractory & metallurgy, pharmaceutical intermediates, food additives, fertilizers, electronic components, water treatment, and others.

Trends in the Application:

- Focusing on extending the lifespan and improving the energy efficiency of refractory linings is a trend positively impacting the market.

- The demand for high purity magnesium oxide-derived products for efficient pH adjustment and phosphate precipitation in water treatment is a key trend.

The refractory & metallurgy segment accounted for the largest high purity magnesium oxide market share of 42.5% in 2024.

- A significant volume of processed high purity MgO is ultimately utilized in the production of essential refractory materials.

- The steel, cement, and glass sectors particularly exhibit a reliance on refractories for lining their critical high temperature processing units, including furnaces, kilns, and converters. In these areas, high purity MgO offers exceptionally high melting points, chemical inertness to basic slags, and excellent thermal stability.

- The large scale of production within these core sectors necessitates a correspondingly large and consistent consumption of compounds in refractory applications.

- For instance, the National Bureau of Statistics of China stated that cement output was 2.02 billion tons in the year 2023. The China Cement Association (CCA) estimated that the capacity utilization rate was 59% in 2023.

- Consequently, as per the analysis, owing to the high adoption in steel, glass, and cement, the refractory & metallurgy segment dominates the high purity magnesium oxide market demand.

The water treatment segment is expected to grow at the fastest CAGR over the forecast period.

- Increasingly stringent environmental regulations worldwide are mandating more rigorous treatment of industrial and municipal wastewater, particularly concerning the removal of harmful pollutants such as heavy metals, phosphates, and sulfates.

- Magnesium oxide of high purity presents effective and more environmental alternatives for meeting these demanding standards.

- It acts as an alkali to neutralize acidic wastewater, precipitate heavy metals, or remove phosphates.

- Its high purity ensures that no unwanted contaminants are introduced into the water during treatment, making it suitable for sensitive applications like industrial wastewater and drinking water treatment.

- Hence, owing to the above-mentioned analysis, the water treatment segment is expected to grow at the fastest rate over the future years, creating high purity magnesium oxide market opportunities.

By End Use:

The end use segment is categorized into construction, electrical & electronics, automotive, pharmaceuticals, food & beverage, agriculture, and others.

Trends in the End Use:

- Increasing use of magnesia-based cement for specialized, rapid-setting, and fire-resistant applications in urban infrastructure is a trend positively impacting the market.

- The growing requirement for high purity MgO-based high-performance alloys in automotive compounds.

The construction segment accounted for the high purity magnesium oxide market share in 2024.

- High purity MgO is utilized in the construction sector primarily in the production of specialized cement, steel, and other building materials.

- The cement incorporated with HP MgO offers unique properties such as rapid hardening, high early strength, good abrasion resistance, and fire resistance among others.

- Furthermore, this highly pure magnesium oxide is also adopted as a component in certain types of wall panels and as a filler in some construction composites.

- The growth in this segment is influenced by the rise in infrastructure development, particularly for specialized industrial and commercial buildings requiring these unique properties.

- Thus, as per the high purity magnesium oxide market analysis, the construction segment is dominating the high purity magnesium oxide market trends.

The automotive segment is expected to grow at the fastest CAGR over the forecast period.

- HP MgO is a crucial component in specialty alloys, enabling them to achieve superior performance in demanding applications. In the automotive sector, their integration enhances the durability and efficiency of parts subjected to elevated temperatures and significant mechanical stress.

- Consequently, the utilization of high-purity magnesium oxide in such alloys actively supports ongoing innovation in transportation technologies, facilitating the creation of safer and more efficient vehicles. Additionally, it is also used in batteries for electric vehicles. Stringent emission regulations and the burgeoning electric vehicle market are key factors.

- For instance, according to the China Association of Automobile Manufacturers, in 2023, China's car output exceeded 30.16 million units, with an 11.6% year-on-year rise.

- This convergence of environmental pressure and technological progress positions the automotive sector as significant growth for consumption trends in the forecast period.

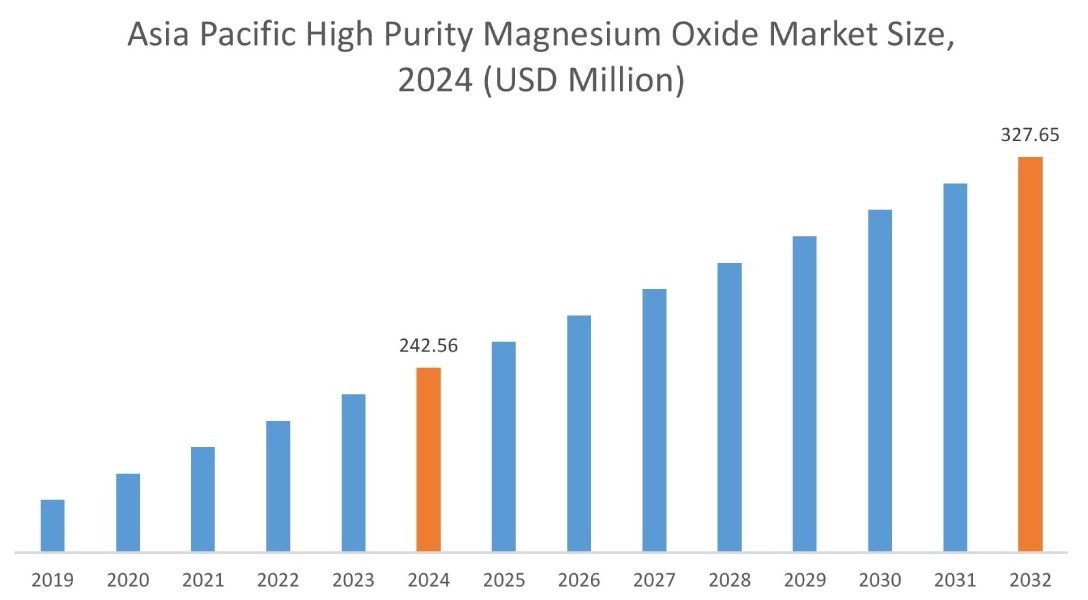

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

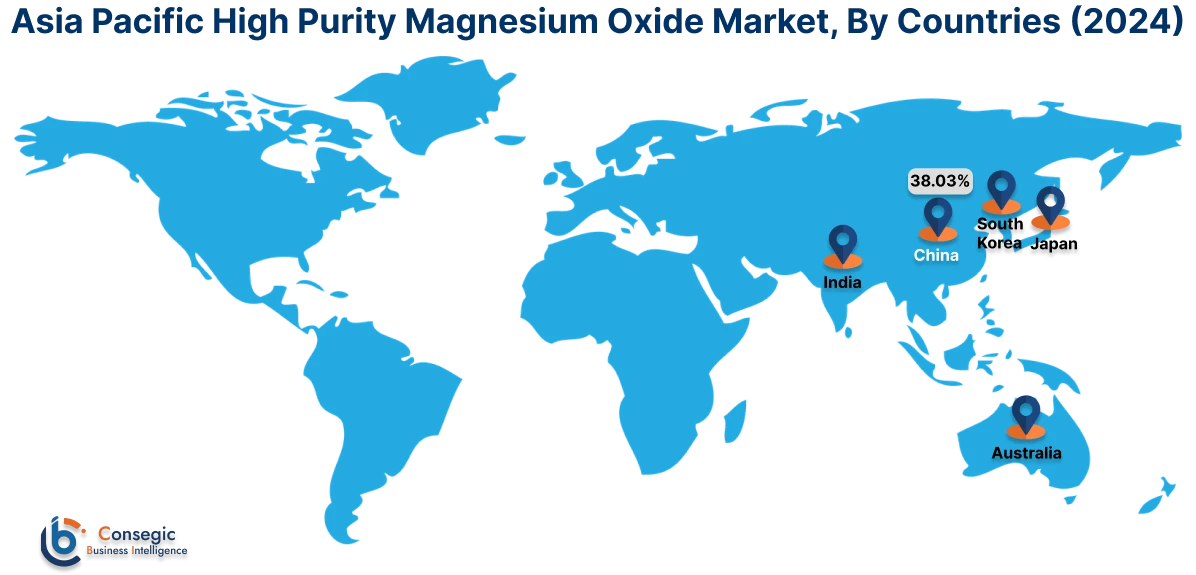

In 2024, Asia Pacific accounted for the highest market share at 40.41% and was valued at USD 242.56 Million and is expected to reach USD 327.65 Million in 2032. In Asia Pacific, China accounted for a market share of 38.03% during the base year of 2024. Asia Pacific's influence on the market is significant due to the region being both the major production hub and dominant consumer. China's significant Magnesite output volume ensures significant raw material availability for HP MgO positions the region as a vital source of the compound. Additionally, the region's robust manufacturing sector, particularly in steel and cement, drives substantial requirements. Moreover, the expanding construction, electronic, and automotive markets are further contributing to the share in this region.

- For instance, according to IBEF, India's consumption of finished steel reached 119.17 million tons in the fiscal year 2023, subsequently rising to 138.5 million tons in FY24.

These factors create a strong upward trajectory for the Asia Pacific market, positioning it as a key region for players.

In Europe, the high purity magnesium oxide industry is experiencing the fastest growth with a CAGR of 6.3% over the forecast period. Industrialized nations across Europe are major consumers, primarily driven by the requirement for high-quality refractories in their established steel, cement, and glass sectors. Furthermore, replacement needs within these mature sectors, coupled with a strong focus on superior refractory performance and the influence of environmental regulations on industrial processes are crucial factors. These factors collectively present a positive impact on the European market.

The North American market for high purity MgO is significantly defined by the high adoption of steel and cement. The region's need for high-quality building and automotive materials all reliant on the compound is driving market revenue. In addition, stringent regulation in the pharmaceutical and food & beverage sectors creates the need for MgO with high purity. Moreover, niche applications in chemicals and environmental treatment play a critical role.

The Latin American high purity magnesium oxide market trend is driven by the region's focus on infrastructure development. The growing investments in manufacturing sectors, particularly in countries such as Brazil, contribute significantly to this requirement, particularly for high purity MgO-based refractories used in their steel and cement sectors. Furthermore, the adoption of the compound in fertilizer and animal feed products further along with the growing agriculture sector contributes to the region's upward market trajectory over the forecast period.

The Middle East and African high purity magnesium oxide market analysis is currently characterized by a reliance on imports. This has led to significant growth potential for the market in the upcoming years. Additionally, increasing infrastructure projects across many countries in the Middle East and Africa are leading to increased requirements for cement. The oil and gas sector, dominant in many Middle Eastern countries, indirectly influences the market through the need for specialized refractories used in petrochemical plants and related high-temperature applications. Supportive government policies are further contributing to the market need in the region. International investments and expertise are further accelerating these initiatives.

Top Key Players and Market Share Insights:

The Global High Purity Magnesium Oxide Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global High Purity Magnesium Oxide market. Key players in the High Purity Magnesium Oxide industry include

- Tateho Chemical Industries Co.,Ltd. (Japan)

- American Elements (U.S.)

- Baymag Inc. (Canada)

- Konoshima Chemical Co.,Ltd. (Japan)

- Celtic Chemicals (United Kingdom)

- TIMAB Magnesium (France)

- Weifang Wanfeng New Material Technology Co., Ltd. (China)

- AKO KASEI CO., LTD. (Japan)

- Martin Marietta Materials (U.S.)

- Grecian Magnesite (Greece)

High Purity Magnesium Oxide Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 870.47 Million |

| CAGR (2025-2032) | 4.8% |

| By Application |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the High Purity Magnesium Oxide market? +

In 2024, the High Purity Magnesium Oxide market is USD 600.25 Million.

Which is the fastest-growing region in the High Purity Magnesium Oxide market? +

Europe is the fastest-growing region in the High Purity Magnesium Oxide market.

What specific segmentation details are covered in the High Purity Magnesium Oxide market? +

By Application and End Use segmentation details are covered in the High Purity Magnesium Oxide market.

Who are the major players in the High Purity Magnesium Oxide market? +

Tateho Chemical Industries Co.,Ltd. (Japan), American Elements (U.S.), TIMAB Magnesium (France), Martin Marietta Materials (U.S.), Baymag Inc. (Canada) are some of the major players in the market.