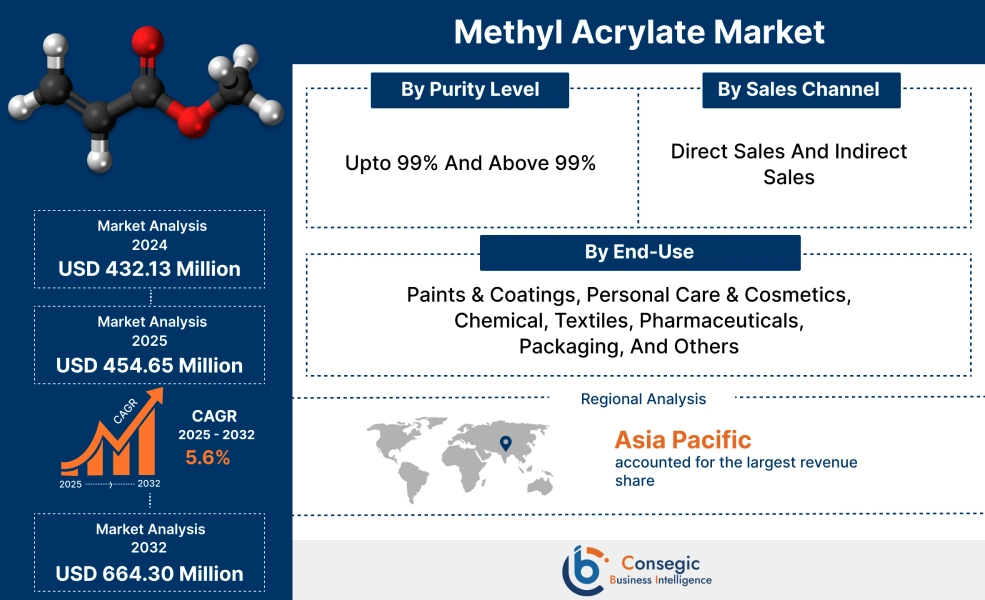

Methyl Acrylate Market Size:

Methyl Acrylate Market size is growing with a CAGR of 5.6% during the forecast period (2025-2032), and the market is projected to be valued at USD 664.30 Million by 2032 from USD 432.13 Million in 2024. Additionally, the market value for the 2025 attributes to USD 454.65 Million.

Methyl Acrylate Market Scope & Overview:

Methyl acrylate (MA) is a molecule with the chemical formula CH₂=CHCOOCH₃. It is the methyl ester of acrylic acid. It is a volatile liquid, less dense than water. It is slightly soluble in water and has a distinctive acrid odor. It is highly flammable and has the ability to easily polymerize. The primary method by which it is produced is the esterification of acrylic acid with methanol. This reaction occurs under acid catalysis. It uses catalysts such as sulfuric acid and p-toluenesulfonic acid among others. It serves as a crucial raw material for various polymers and copolymers used in diverse applications.

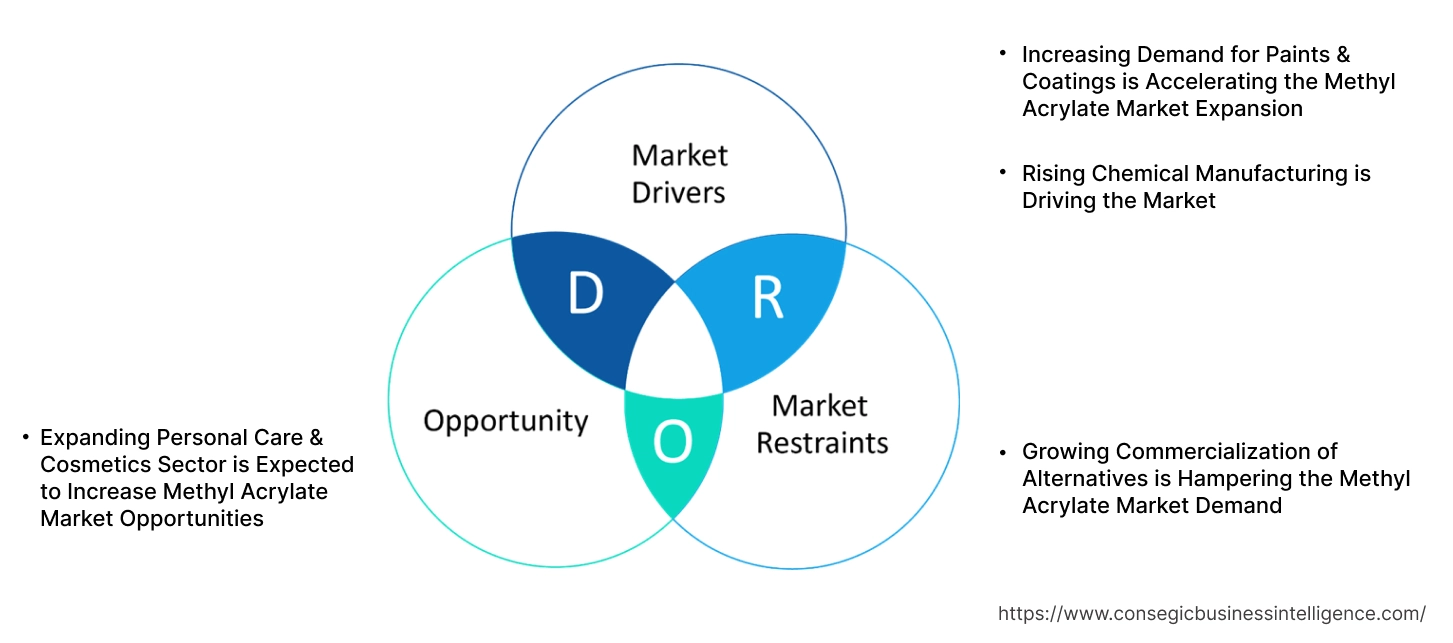

Methyl Acrylate Market Dynamics - (DRO) :

Key Drivers:

Increasing Demand for Paints & Coatings is Accelerating the Methyl Acrylate Market Expansion.

Methyl acrylate is a valuable monomer in paints and coatings. It increases the hardness and strength of acrylic and vinyl-acrylic resins. This leads to more durable coatings. Moreover, coatings which are formulated with this monomer exhibit good water resistance. This makes them suitable for exterior applications. Additionally, it is beneficial in providing superior resistance to UV radiation. This ensures the longevity and color retention of paints and coatings. Furthermore, it has higher polarity. This increases adhesion to various surfaces. It also ensures better bonding for paints and coatings. Rapid urbanization and infrastructure development have led to an increase in demand for paint & coatings, hence requiring this monomer for multiple applications.

For instance,

- According to ORIM Advisors, the Indian paint industry demonstrated strong growth between FY19 and FY23, achieving a CAGR of 14%–15%, thus positively impacting methyl acrylate market trends.

Overall, the increasing need for paints & coatings is significantly boosting the methyl acrylate market expansion.

Rising Chemical Manufacturing is Driving the Market.

Methyl acrylate monomer offers several key benefits in chemical manufacturing. Its double bond allows it to readily undergo polymerization. This is beneficial in forming homopolymers. Moreover, it contributes superior strength and durability to these resulting polymers. Additionally, they serve as a crucial intermediate in the synthesis of various organic compounds and specialty chemicals. Furthermore, it imparts desirable attributes such as good water resistance and excellent UV to these polymers. Rising need from various end-use sectors such as electronics and healthcare has increased the production the chemicals, hence needing this monomer as a main component.

For instance,

- According to the United States International Trade Commission, U.S. chemical exports increased by 25% in 2021 when compared to the previous year, thus positively impacting the methyl acrylate market trends.

Thus, increasing chemical manufacturing is accelerating the global methyl acrylate market growth.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Methyl Acrylate Market Demand.

The market faces competition from other substitutes available in the market. For instance, butyl acrylate monomer imparts significant flexibility and toughness to polymers. This makes it highly advantageous in applications requiring pliability and impact resistance. Moreover, ethyl acrylate provides excellent durability, water repellency, stain resistance, and good weatherability in coatings and textiles. It is chosen for its ability to enhance adhesion, mechanical strength, and overall longevity of materials. Additionally, vinyl acetate monomer is a cost-effective alternative for multiple applications. This includes adhesives, sealants, and binders among others. Hence, the growing commercialization of substitutes is hampering the methyl acrylate market demand.

Future Opportunities :

Expanding Personal Care & Cosmetics Sector is Expected to Increase Methyl Acrylate Market Opportunities.

Methyl Acrylate monomer is used as a raw material in various products such as hair styling gels, nail polishes, BB creams, blushes, and eye creams among others. These monomers create a thin, protective film on the skin and hair. They improve the texture, feel, and spreadability of formulations. This creates a smoother and more luxurious sensory experience. Moreover, they absorb excess oil and sebum from the skin's surface. This provides a mattifying effect and reduces shine. The influence of social media and growing awareness of self-appearance has led to sector growth, hence creating potential for the market.

For instance,

- According to an article published by the Israeli Foreign Trade Administration, in 2024, the UAE's beauty market is expected to grow at a CAGR of 5% over the next 5 years. This creates potential for the market.

Overall, the expanding personal care & cosmetics sector is expected to increase the methyl acrylate market opportunities.

Methyl Acrylate Market Segmental Analysis :

By Purity Level :

Based on purity level, the market is categorized into upto 99% and above 99%.

Trends in Purity Level:

- There is a growing trend of using above 99% purity due to stringent requirements in specialized applications such as pharmaceutical synthesis.

- The upto 99% purity is utilized more due to its broader applicability in traditional industrial uses such as paints and textiles among others.

The upto 99% segment accounted for the largest market share in 2024.

- Upto 99% purity refers to a grade where the desired chemical constitutes at least 99% of the total substance by weight.

- The primary advantage of this purity level is cost-effectiveness. For applications where minor impurities do not adversely affect the end product's performance, the upto 99% grade offers a more economical solution.

- It is used as a monomer in emulsions for architectural and industrial coatings. It offers them flexibility and weather resistance properties.

- Moreover, in pressure-sensitive adhesives, it enables strong and durable bonds. Additionally, it is used for treating fabrics. They enhance properties such as strength, water resistance, and feel.

- Furthermore, it is used as a raw material for synthesizing various organic chemicals. All these benefits are driving its increased usage.

- Overall, as per the market analysis, the aforementioned factors are driving a segment in the methyl acrylate market growth.

The above 99% segment is expected to grow at the fastest CAGR over the forecast period.

- Above 99% purity signifies a highly refined product. It includes reaching purity of 99.5% and 99.9%.

- Higher purity ensures predictable reaction kinetics. This leads to consistent product quality and reduced batch-to-batch variations.

- It minimizes unwanted side reactions or discoloration. This extends product life and improves overall efficiency.

- It is primarily used for manufacturing various pharmaceutical and specialty chemical products. Growth in these industries will drive the segment.

- For instance, EuroDev BV, the European pharmaceutical market is expected to grow at a CAGR of 5.4% from 2023 to 2028.

- According to the methyl acrylate market analysis, the aforementioned factors will drive the segmental share for the upcoming years.

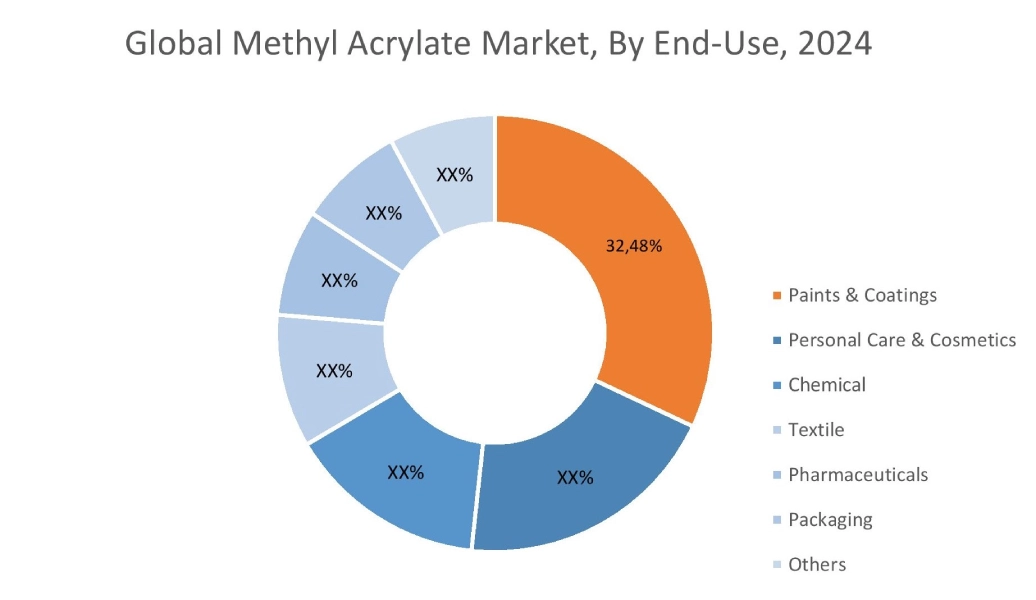

By End Use:

Based on end-use, the market is categorized into paints & coatings, personal care & cosmetics, chemical, textiles, pharmaceuticals, packaging, and others.

Trends in the End-Use

- As a versatile chemical intermediate, methyl acrylate is continuously used for synthesizing various specialty chemicals and other organic compounds.

- Growing trend of using methyl acrylate in the textile industry for treating fabrics. This improves their strength and water resistance.

The paints & coatings segment accounted for the largest market share of 32.48% in 2024.

- Methyl acrylate benefits paints and coatings in multiple ways. It improves adhesion, flexibility, and durability.

- Moreover, it also providesresistance to environmental factors such as weather and chemicals.

- It is a building block for acrylic and methacrylic polymers, which are crucial for forming durable films on surfaces.

- Moreover, they also contribute to low odor, color, and volatility in coatings. This makes them suitable for various applications.

- The growing automotive and construction sectors are leading to increased demand for paint & coating.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the methyl acrylate industry.

The personal care & cosmetics segment is expected to grow at the fastest CAGR over the forecast period.

- Methyl acrylate is used in products such as creams, lotions, serums, sunscreens, hair masks, concealers, and foundation among others.

- They are helpful in fixing active ingredients in place. This ensures that they are released gradually and effectively into the skin or hair.

- It is used to improve the texture of cosmetic products. This makes them smoother and easier to apply.

- Rising disposable incomes, awareness regarding grooming, and the influence of social media have led to an increase in product demand, creating potential.

- For instance, according to an article published by Happi, in 2023, U.S. skincare product sales have increased by 10% in the last five years.

- Thus, according to market analysis, the aforementioned factors will drive segment for the forecasted years.

By Sales Channel:

Based on sales channel, the market is categorized into direct sales and indirect sales.

Trends in the Sales Channel

- Manufacturers are increasingly adopting e-commerce and digital platforms for sales. This enables 24/7 access to product information, real-time inventory updates, and streamlined order processing.

- Manufacturers are leveraging direct sales to provide specialized technical expertise and application support. This is necessary for complex formulations and niche applications.

The direct sales segment accounted for the largest market share in 2024.

- Direct sales refer to manufacturers selling their products directly to end-use industries. It bypasses intermediaries such as distributors and wholesalers.

- Closer relationships between manufacturers and end-users foster a deeper understanding of customer-specific needs.

- This enables manufacturers to offer tailored solutions, technical support, and faster response times for inquiries.

- Moreover, manufacturers maintain full control over the sales process, brand messaging, and product delivery. This reduces the risk of product dilation.

- Additionally, direct engagement provides valuable real-time feedback. This data helps in forecasting demand and adapting to evolving market trends. All these benefits drive the sales of products through this channel.

- Overall, as per the market analysis, the aforementioned factors are driving the segment in the market.

The indirect sales segment is expected to grow at the fastest CAGR over the forecast period.

- Indirect sales channels include resellers and distributors, selling products both offline and online.

- Indirect channels allow manufacturers to access a much wider customer base. This includes smaller businesses and those in geographically diverse locations.

- By leveraging the existing sales teams, warehousing, logistics, and marketing efforts of distributors, manufacturers are reducing their own operational costs associated with sales and distribution. These benefits are driving the sales of products through this channel.

- For instance, SellersCommerce, U.S. e-commerce market is expected to grow at a CAGR of more than 8% in 2025.

- Thus, according to market analysis, the aforementioned factors will drive segment for the forecasted years.

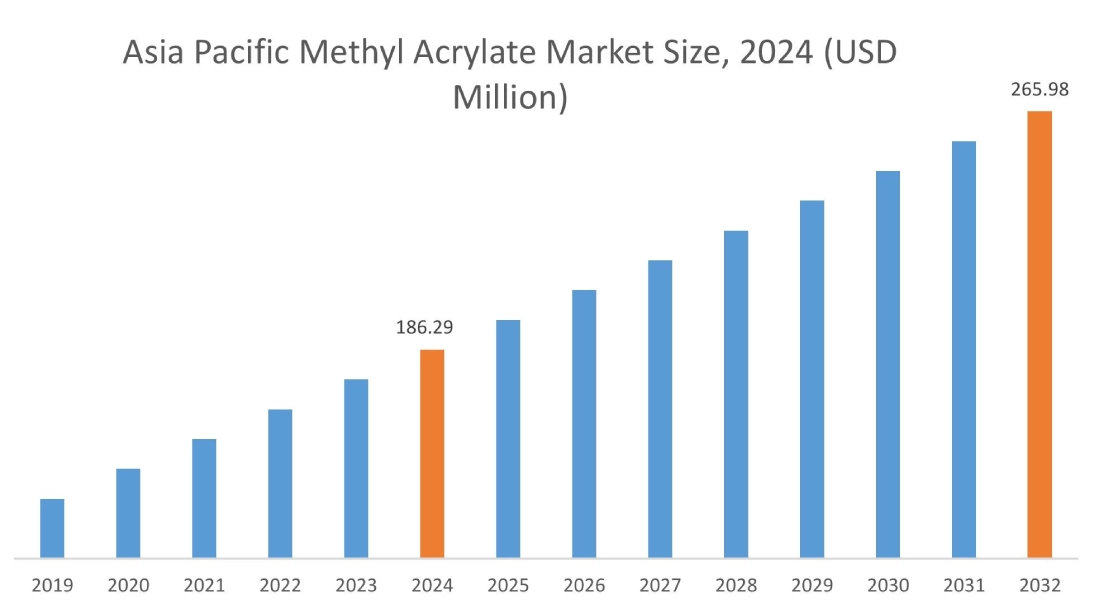

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

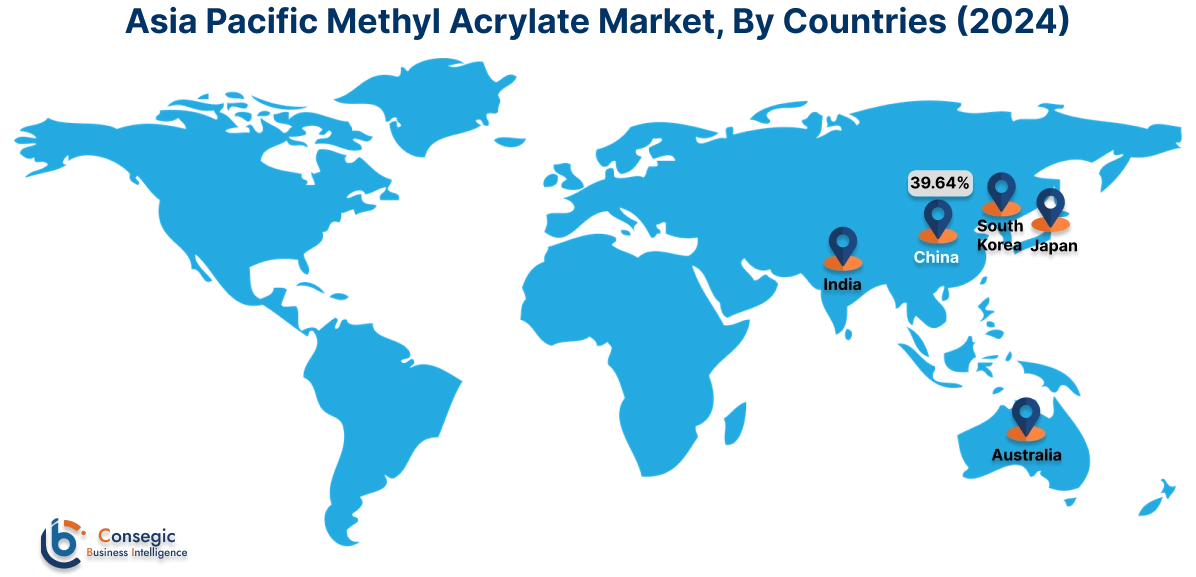

In 2024, Asia Pacific accounted for the highest methyl acrylate market share at 43.11% and was valued at USD 186.29 Million and is expected to reach USD 265.98 Million in 2032. In Asia Pacific, the China accounted for the methyl acrylate market share of 39.64% during the base year of 2024. There is rapid urbanization and industrialization in the region, which has driven the need for architectural, automotive, and industrial coating, leading to increased production. Countries such as China, India, and South Korea lead the market.

For instance,

- According to Senbaoli Chemical, China's coating output grew by 4.5% in the year 2023, when compared to the previous year.

Methyl acrylate offers significant benefits in coatings. It has the ability to polymerize rapidly. This forms durable and flexible films. This enhances weather resistance, UV stability, chemical resistance, and adhesion. Its excellent copolymerization characteristics allow for diverse formulations such as water-based and low-VOC. Overall, growing coatings production is driving the market in the region.

In Europe, the methyl acrylate market is experiencing the fastest growth with a CAGR of 7.5% over the forecast period. The market is driven by technological advancements in production. European chemical manufacturers are at the forefront of innovating methyl acrylate synthesis processes. This includes the development and adoption of more efficient catalysts, optimized reaction conditions, and continuous flow reactors. Energy-saving processes and reduced raw material consumption are contributing to a more competitive pricing structure. Additionally, they are heavily invested in sustainable practices. This leads to processes with lower emissions. Furthermore, more efficient conversion of raw materials results in higher yields, reducing waste.

North America’s methyl acrylate market analysis indicates that several key trends are contributing to its growth in the region. There is growth in chemical production driven by diverse usage across various industries. The region boasts a robust chemical manufacturing base, with continuous investments by major players such as Dow and BASF to expand production capacities for methyl acrylate and its derivatives. Moreover, its application in adhesives and sealants for packaging, construction, and specialized industrial uses is consistently increasing. Additionally, as a fundamental chemical intermediate, it is vital for synthesizing a wide range of specialty chemicals and plastic additives.

Middle East and Africa (MEA) market analysis indicates that there is an escalating need for personal care and cosmetics in the region. As disposable incomes rise and urbanization accelerates across the MEA, consumers are increasingly investing in a wider range of beauty products. Methyl acrylate plays a crucial role in these formulations. It is used as a monomer to enhance the feel of products such as nail polishes, mascaras, and hair gels. Its derivatives also act as viscosity modifiers and emulsifiers. This contributes to the desired texture and stability of creams, lotions, and other skincare items.

Latin America's region creates potential for the market. There is a growing textile sector in the region. Methyl acrylate in textile manufacturing is used to enhance fabric properties. They make textiles more resistant to wear and tear. Moreover, it is crucial for sportswear, outdoor gear, and certain home textiles, as it provides excellent water-resistant properties. Additionally, it contributes to softer and more rigid fabrics as desired. Furthermore, it is used in interior/exterior components of automotive to improve fuel efficiency and enhance aesthetic appeal. Countries such as Brazil, Argentina, and Chile lead the market.

Top Key Players and Market Share Insights:

The Methyl Acrylate market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Methyl Acrylate market. Key players in The Methyl Acrylate industry include-

- BASF SE (Germany)

- LG Chem (South Korea)

- Evonik Industries AG (Germany)

- Sibur International (Austria)

- Formosa Plastics Corporation (Taiwan)

- Shandong Kaitai Petrochemical Co., Ltd. (China)

- Arkema S.A. (France)

- Muby Chemicals (India)

- Mitsubishi Chemical Corporation (Japan)

- Dhalop Chemicals (India)

- Dow, Inc. (United States)

- Nippon Shokubai Co., Ltd. (Japan)

Methyl Acrylate Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 664.30 Million |

| CAGR (2025-2032) | 5.6% |

| By Purity Level |

|

| By End Use |

|

| By Sales Channel |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Methyl Acrylate market? +

In 2024, the Methyl Acrylate market is USD 432.13 Million.

Which is the fastest-growing region in the Methyl Acrylate market? +

Europe is the fastest-growing region in the Methyl Acrylate market.

What specific segmentation details are covered in the Methyl Acrylate market? +

Purity Level, End-Use, and Sales Channel segmentation details are covered in the Methyl Acrylate market.

Who are the major players in the Methyl Acrylate market? +

BASF SE (Germany), Arkema S.A. (France), Muby Chemicals (India), Mitsubishi Chemical Corporation (Japan), Dhalop Chemicals (India), Dow, Inc. (United States), and Nippon Shokubai Co., Ltd. (Japan) are some major players in the market.