Operational Technology Market Size:

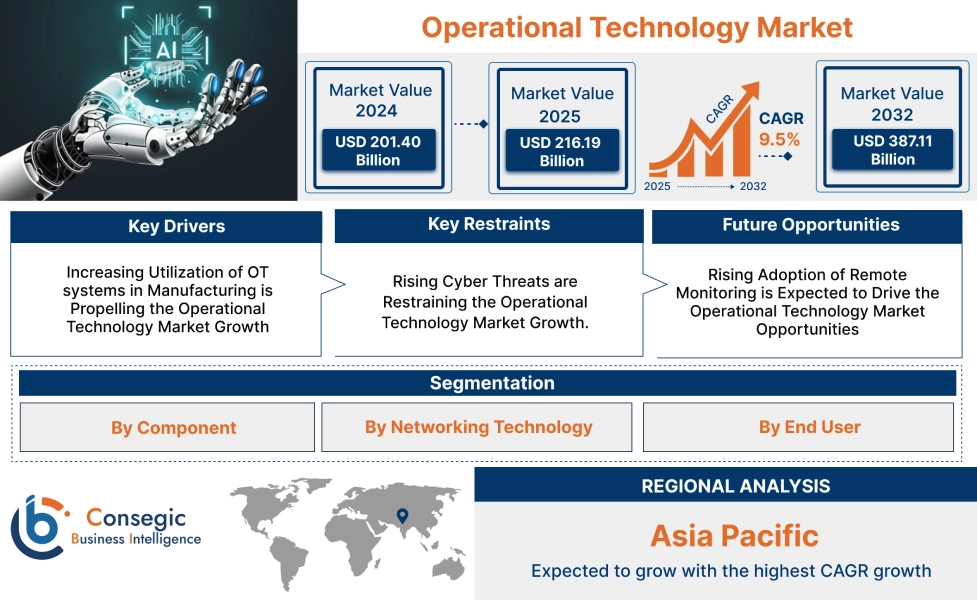

Operational Technology Market size is estimated to reach over USD 387.11 Billion by 2032 from a value of USD 201.40 Billion in 2024 and is projected to grow by USD 216.19 Billion in 2025, growing at a CAGR of 9.5% from 2025 to 2032.

Operational Technology Market Scope & Overview:

Operational technology or OT refers to hardware and software that controls and monitors how devices perform in industrial settings. OT systems help in controlling physical processes and infrastructure in asset-intensive sectors including energy and mining. Further, the integration of remote access, monitoring, and control of physical devices has driven the market. Moreover, the rising adoption of operational technology in water and waste management to manage water treatment facilities is driving the market.

Operational Technology Market Dynamics - (DRO) :

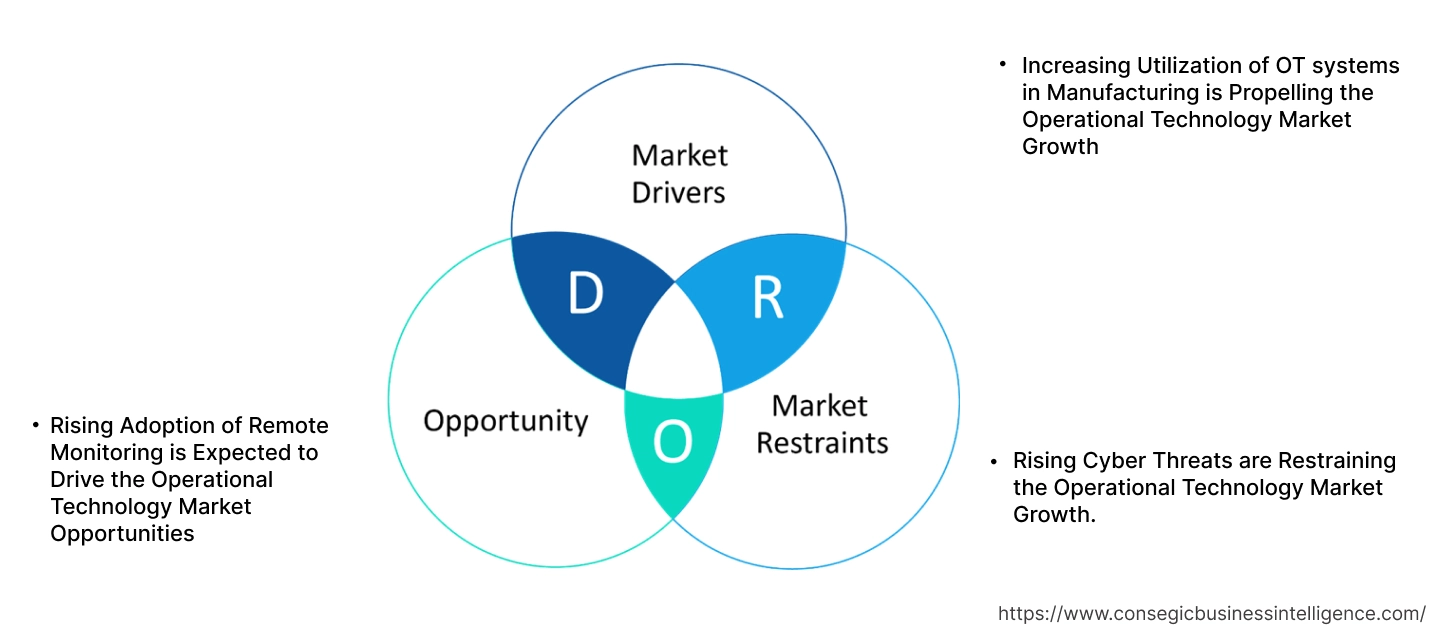

Key Drivers:

Increasing Utilization of OT systems in Manufacturing is Propelling the Operational Technology Market Growth

Organizations have started investing in OT systems including industrial control systems and programmable logic controllers to manage machines and robots. Further, supervisory control and data acquisition systems are utilized in manufacturing to collect data including performance metric from connected machinery. Additionally, manufacturers have started offering programmable logic controllers for machine automation in manufacturing which is driving the overall market.

- For instance, according to the Ministry of Commerce & Industry (India), Index of Industrial Production growth rate in the month of December 2024 stood at 3.2 %. The rise in manufacturing is expected to boost the market as OT systems are used in manufacturing for operating and monitoring machinery.

Hence, the increasing utilization of OT systems in manufacturing to manage machines and robots is driving the operational technology market size.

Key Restraints:

Rising Cyber Threats are Restraining the Operational Technology Market Growth.

OT systems are vulnerable to cybersecurity attack can cause disruption in manufacturing. Further, cyberattacks on the OT systems endanger critical infrastructure. Moreover, malware can target industrial control system devices affecting various sectors including energy and manufacturing which can act as a restraint to the market growth. Thus, rising cyber threats due to attacks on industrial control system devices act as a restraint to the operational technology market expansion.

Future Opportunities :

Rising Adoption of Remote Monitoring is Expected to Drive the Operational Technology Market Opportunities

Manufacturers have started utilizing remote monitoring in OT systems including SCADA systems to identify patterns and detect anomalies remotely. Additionally, data acquisition systems have experienced integration of remote monitoring in various industries including pharmaceuticals and food and beverage which is driving the market. Moreover, companies have started utilizing remote solutions including wireless sensors for warehousing monitoring which is driving the market.

- For instance, Monnit offers IoT based remote monitoring systems for logistics and warehouse monitoring. The rise in remote monitoring systems in warehouses is expected to boost the market.

Thus, the rising adoption of remote monitoring in pharmaceuticals, food and beverage, and warehouse is expected to drive the operational technology market opportunities during the forecast period.

Operational Technology Market Segmental Analysis :

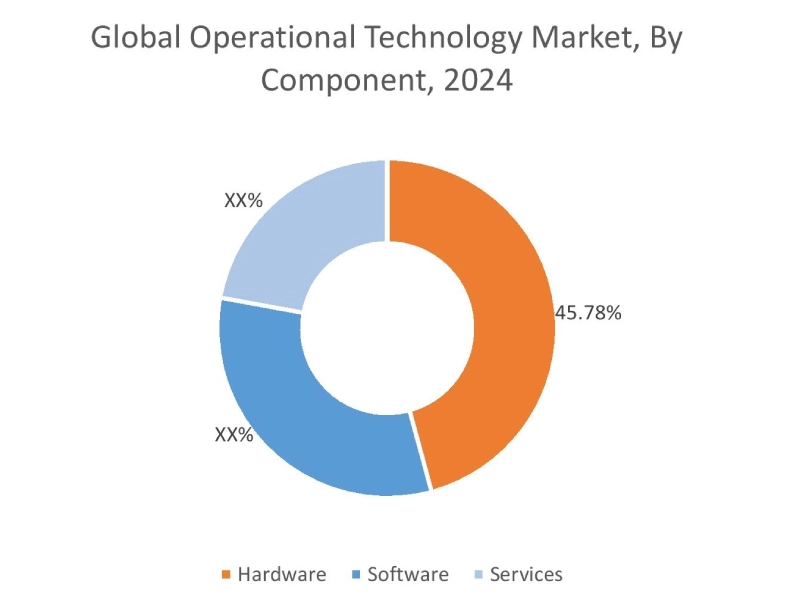

By Component:

Based on the component, the market is segmented into hardware, software, and services.

Trends in the component:

- Increasing adoption of hardware namely industrial PCs and workstations that feature aluminium housings is driving the operational technology market share.

- Rising utilization of warehouse management software for real-time visibility into a company’s inventory is driving the operational technology market trends.

Hardware accounted for the largest revenue share of 45.78% in the year 2024.

- In hardware, field instruments specifically pressure transmitters have experienced a rising adoption due to real-time monitoring of pressure levels, which has resulted in the operational technology market expansion.

- Additionally, there has been a rising adoption of controllers with expanded memory for faster data processing which is driving the global operational technology market.

- Moreover, the increasing utilization of panel-based human-machine interfaces that feature vector-based visualization is driving the market.

- For instance, Siemens offers the SIMATIC HMI Unified Panels that features a web client for remote operation. The rise in the number of offerings for human-interface panels is expected to boost the market.

- According to the market analysis, the rising advancements related to hardware due to real-time monitoring of pressure levels and vector-based visualization is driving the operational technology market trends.

Software is anticipated to register the fastest CAGR during the forecast period.

- There has been a rising adoption of supervisory control and data acquisition (SCADA) system in energy sector to enable real-time visualisation of electricity distribution across the network.

- Moreover, the rising utilization of distributed control systems (DCS) to automate industrial equipment used in continuous and batch process is boosting the market.

- For instance, in March 2024, ABB unveiled the ABB Ability Symphony SDe Series distributed control system. The company aims to assist customers to ensure their plants meet regulatory requirements and increase efficiency.

- Thus, the increasing utilization of software due to real-time visualization of electricity and automation of industrial equipment in batch and continuous processes is driving the overall market.

By Networking Technology:

Based on the networking technology, the market is segmented into wired and wireless.

Trends in the networking technology:

- Increasing adoption of wired specifically wired PCs that feature a fanless design is driving the market trends.

- There has been a rising utilization of wireless devices due to reduction in installation complexity which is driving the operational technology market demand.

Wired segment accounted for the largest revenue share in the year 2024.

- Wired OT systems have experienced a rising adoption in the market due to increased stability of connection.

- Further, the rising utilization of the wired networks for certain applications including industrial control systems and SCADA systems is driving the operational technology market demand.

- Moreover, wired networks have experienced a rising adoption in automation equipment including industrial robots which is driving the market.

- Thus, as per the analysis, the rising adoption of wired due to increased stability of connection is driving the market.

Wireless is anticipated to register the fastest CAGR during the forecast period.

- Wireless OT systems have experienced a rising adoption due to their ability to reach hard-to-reach location in industries.

- Moreover, wireless systems reduce the overall space, weight, and power requirements which has driven the market.

- For instance, Schneider Electric offers a battery powered wireless data logger that features analog, digital, and modbus inputs. The rise in the adoption of wireless data loggers is expected to boost the market.

- Therefore, the rising utilization of wireless due to reduced space and weight is driving the market.

By End User:

Based on the end user, the market is segmented into manufacturing, energy, oil and gas, food and beverage, chemicals, automotive, semiconductor and electronics, and others.

Trends in the end user:

- Increasing adoption of OT systems in manufacturing due to reduced labor costs is driving the market trends.

- Rising adoption of operational technology specifically data acquisition systems in semiconductors and electronics for data logging, measurement, and monitoring is driving the market growth.

Manufacturing accounted for the largest revenue share in the year 2024.

- OT systems have experienced a rising adoption in manufacturing to enhance safety due to monitoring of hazardous conditions which has driven the global operational technology market.

- Further, rising utilization of the systems in manufacturing to manage assembly lines is driving the market demand.

- Moreover, the increasing utilization adoption of MES software in manufacturing to track and document the transformation of raw materials into finished products is driving the market.

- Therefore, the increasing demand for OT systems in manufacturing to manage assembly lines and enhance safety is driving the operational technology market size.

Semiconductor and electronics is anticipated to register the fastest CAGR during the forecast period.

- OT systems including industrial PCs/workstations have experienced a rising adoption in semiconductor and electronics due to protection against dust and electromagnetic interference which has driven the market.

- Moreover, the rise in the adoption of OT systems including manufacturing execution systems and industrial automation systems in electronics to change machine configurations and operation sequences through computer interfaces is driving the growth of the market.

- For instance, MKS offers Automation Platform to provide automation in semiconductor fabs. The rise in the number of offerings by companies to automate lot selection and alarm handling in semiconductor manufacturing is expected to boost the market.

- According to the operational technology market analysis, the rising trend in the adoption of OT systems in semiconductor and electronics to protect against electromagnetic interference and change machine configurations is propelling the operational technology industry during the forecast period.

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

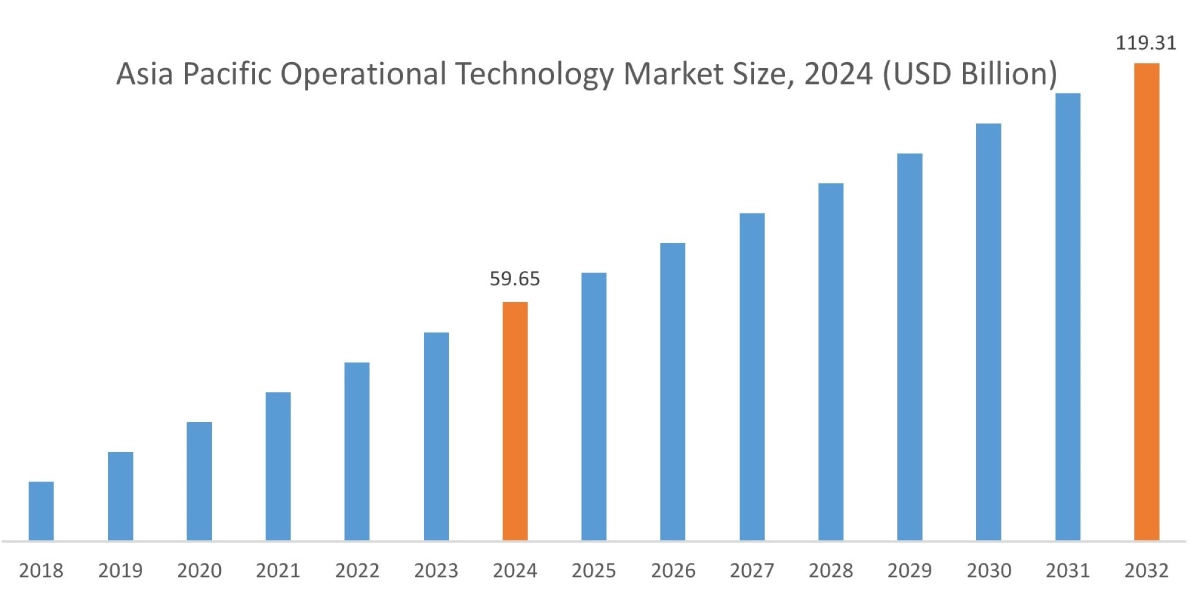

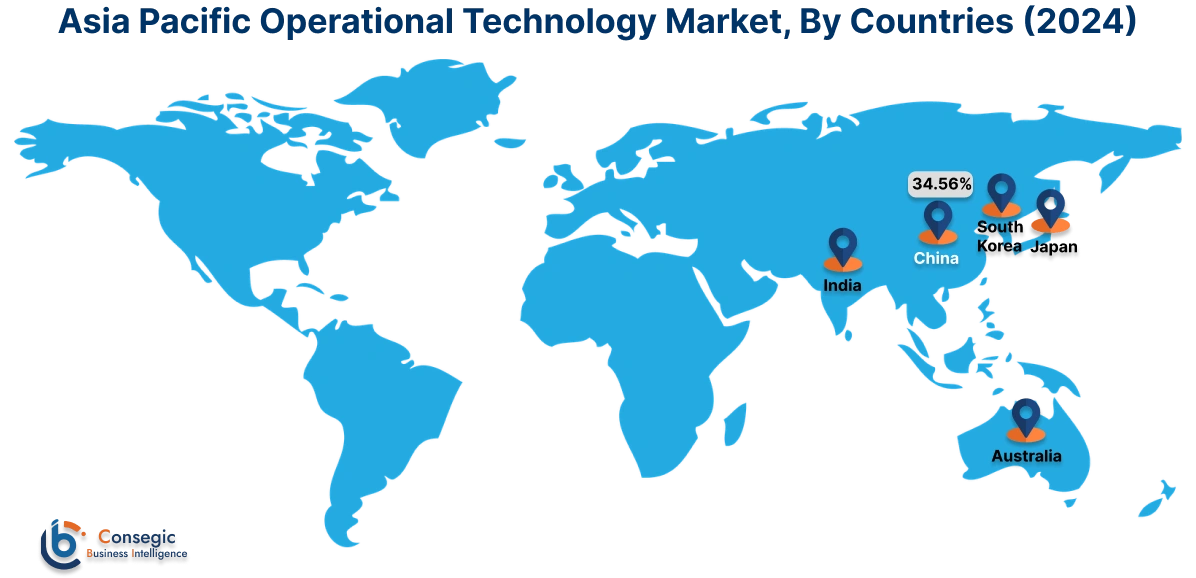

Asia Pacific region was valued at 59.65 Billion in 2024. Moreover, it is projected to grow by 64.25 Billion in 2025 and reach over 119.31 Billion by 2032. Out of this, China accounted for the maximum revenue share of 34.56%. As per the operational technology market analysis, the growth in the Asia-Pacific region is primarily driven by the increasing technological advancements in hardware OT systems and rising investments in semiconductor manufacturing.

- For instance, according to the Ministry of Electronics and IT, the Indian government approved the Semicon India programme that aims to provide approximately USD 9 billion for the development of semiconductor manufacturing. The rise in investments in semiconductor manufacturing is expected to boost the market as OT systems are utilized in semiconductor fabs.

North America is estimated to reach over USD 123.76 Billion by 2032 from a value of USD 64.12 Billion in 2024 and is projected to grow by USD 68.85 Billion in 2025. In North America, the growth of operational technology industry is driven by the increasing adoption of software OT systems. Moreover, the increasing utilization of the OT systems by pharmaceuticals has resulted in the rise of operational technology market share.

- For instance, according to FRED, the manufacturers’ value of pharmaceutical and medicine manufacturing shipments stood at USD 21,504 millions of dollars in January 2025 increasing from 20,028 in January 2024. The rise in pharmaceutical and medicine manufacturing is expected to boost the market as OT systems are used in pharmaceutical to maintain product quality.

Additionally, the regional analysis depicts that the rising investment in the automotive sector is driving the market demand in Europe. Furthermore, as per the market analysis, the market demand in Latin America is expected to grow at a considerable rate due to rising investments by food and beverage companies to automate and manage industrial equipment. Middle East and African regions are expected to grow at a considerable rate due to factors such as growing investments in oil and gas and rising GDP among others.

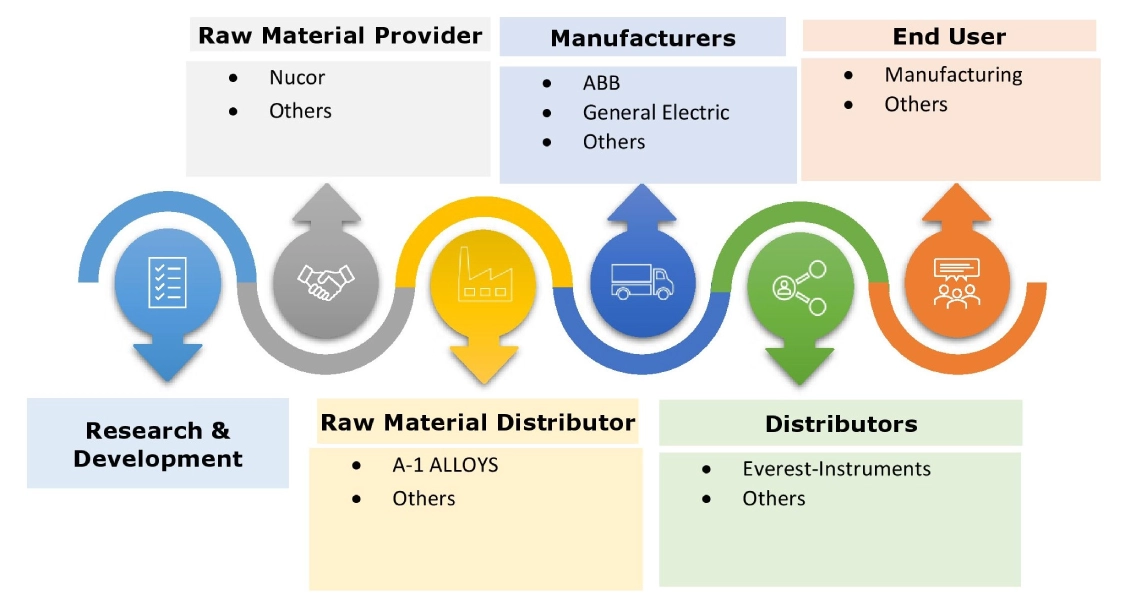

Top Key Players and Market Share Insights:

The global operational technology market is highly competitive with major players providing solutions to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the operational technology market. Key players in the operational technology industry include-

Recent Industry Developments :

Product Launch

- In February 2025, ICONICS unveiled GENESIS, a next-gen SCADA automation and digitalization platform. The software features advanced visualization, improvised system control, and asset modeling with unified namespace. The company aims to empower organizations to transform and optimize industrial operations through the software.

Operational Technology Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 387.11 Billion |

| CAGR (2025-2032) | 9.5% |

| By Component |

|

| By Networking Technology |

|

| By End User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the operational technology market? +

The operational technology market was valued at USD 201.40 Billion in 2024 and is projected to grow to USD 387.11 Billion by 2032.

Which is the fastest-growing region in the operational technology market? +

Asia-Pacific region is experiencing the most rapid growth in the operational technology market.

What specific segmentation details are covered in the operational technology market report? +

The operational technology market report includes component, networking technology, end user and region.

Who are the major players in the operational technology market? +

The key participants in the operational technology market are ABB (Switzerland), Siemens (Germany), Honeywell International Inc. (U.S.), General Electric (U.S.), Yokogawa Electric (Japan), Robert Bosch GmbH (Germany), Omron Corporation (Japan), Delta Electronics, Inc. (Taiwan), FANUC CORPORATION (Japan), Schneider Electric (France), and Others.