Surface Mount Technology Equipment Market Scope & Overview:

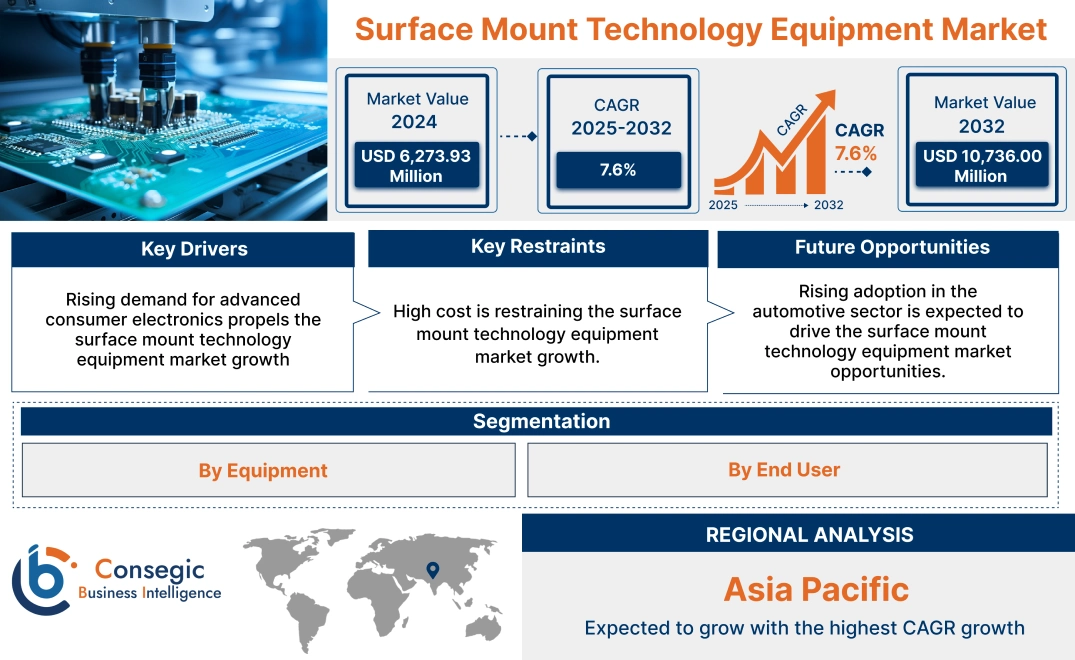

Surface Mount Technology Equipment Market size is estimated to reach over USD 10,736.00 Million by 2032 from a value of USD 6,273.93 Million in 2024 and is projected to grow by USD 6,600.55 Million in 2025, growing at a CAGR of 7.6% from 2025 to 2032

Surface Mount Technology Equipment Market Size:

Surface mount technology (SMT) equipment refers to specialized machines that are used in surface-mount technology for assembling printed circuit boards (PCBs). SMT equipment such as placement equipment is used for placing surface-mount components onto a printed circuit board. Meanwhile, SMT inspection equipment is utilized during the inspection phase of SMT assembly lines for examining PCBs for defects and errors, while SMT soldering equipment is used for attaining a flawless solder paste deposition with seamless alignment and reliable electrical connections during electronic assembly. Moreover, surface mount technology equipment offers a range of benefits, including ease of utilization, higher precision, faster assembly speed, consistency, and flexibility in operations. The aforementioned benefits of SMT equipment are primary determinants for increasing its application in consumer electronics, automotive, aerospace & defense, healthcare, and other industrial sectors.

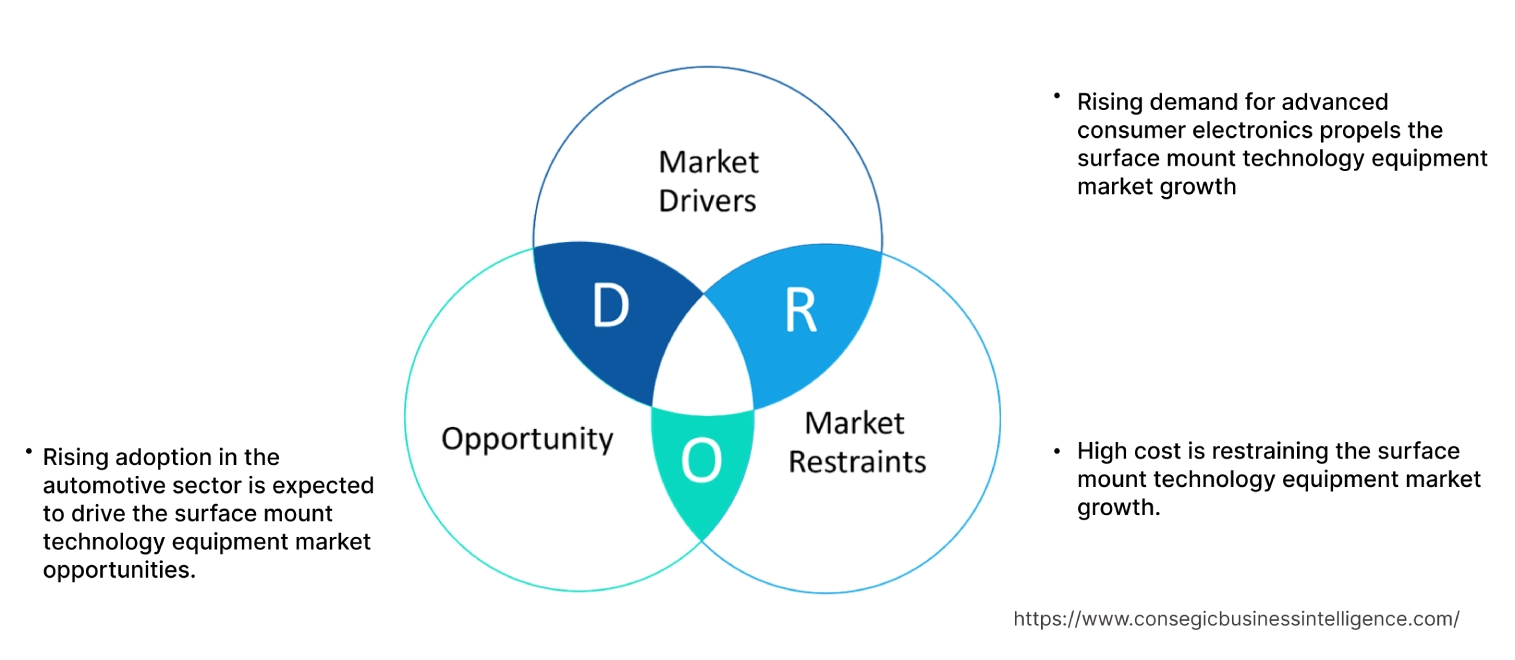

Key Drivers:

Rising adoption in consumer electronics sector is propelling the surface mount technology equipment market growth

A variety of consumer electronics products integrated with PCBs need surface mount technology equipment for mounting various electronic product components. Surface mount technology equipment is primarily used in the consumer electronics sector to place surface-mount components onto a printed circuit board. Moreover, SMT equipment consists of multiple mount heads that are capable of simultaneously performing a variety of component placements. The utilization of SMT equipment offers a range of benefits, including facilitation of miniaturized components, increased automation, maximum flexibility in building PCBs, improved performance and reliability, reduced manual intervention for component placement, ease of PCB assembly, and others. The above benefits of surface mount technology equipment are primary determinants for increasing its adoption during PCB assembly in consumer electronics devices.

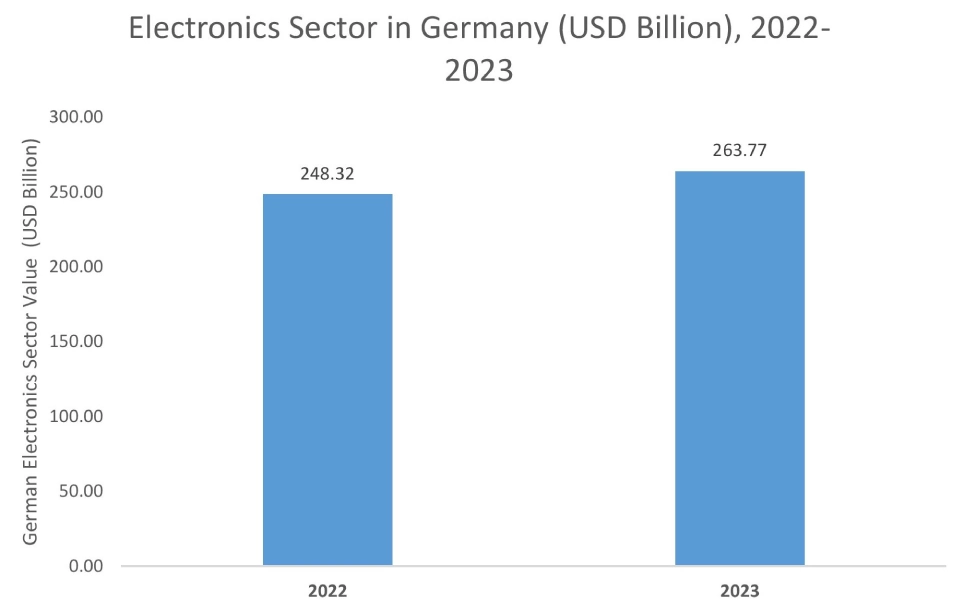

- For instance, according to the German Electrical and Electronic Manufacturer’s Association (ZVEI), the electronics production in Germany witnessed an annual growth rate of 3.7% in 2022. Additionally, the electronics sector in Germany was valued at USD 263.77 billion in 2023, witnessing an increase of 6% from USD 248.32 billion in 2022.

Thus, the growing electronics sector is driving the application of SMT equipment for mounting various electronic product components onto a printed circuit board, in turn proliferating the surface mount technology equipment market size.

Key Restraints :

Operational limitations and high costs associated with SMT equipment are restraining the surface mount technology equipment market

The implementation of SMT equipment is often associated with certain operational limitations and high cost, which are prime factors limiting the market demand. Moreover, surface mount technology is associated with certain operational limitations, including relatively difficult inspection, lower power, ease of damage, and expensive small batch production, among others.

- For instance, Neoden Technology Co., Ltd. offers several types of SMT equipment including placement equipment, inspection equipment, SMT stencil printers, and others. Neoden offers a range of manual and semi-automatic SMT stencil printers with average costs starting from USD 1,000 per unit for manual stencil printers to USD 8,000 or more per unit for semi-automatic SMT stencil printers. Additionally, Neoden offers multiple SMT pick and place machines with an average price ranging from USD 3,999 to USD 29,999 per unit, depending on the specification of the equipment, which is relatively very high.

Therefore, the above limitations and high costs associated with SMT equipment are hindering the surface mount technology equipment market expansion.

Future Opportunities :

Increasing application in automotive sector is expected to drive the surface mount technology equipment market opportunities

SMT equipment is primarily utilized in the automotive sector, particularly during the assembly of PCBs in automobile electronics systems, including on-board vehicle control system, infotainment system, telematics system, advanced driver assistance system (ADAS), and others. SMT equipment enables accurate mounting of tiny electronic components on the circuit board of the on-board vehicle control system to attain stable and efficient control functions. Similarly, SMT equipment provides high-precision placement support for manufacturing of actuators and sensors used in automotive electronics while ensuring their accuracy and sensitivity.

Moreover, SMT equipment also enables quicker and accurate mounting of several electronic components on PCBs of automobile infotainment system and advanced driver assistance system, which helps in attaining improved system performance. The above characteristics of SMT equipment are driving its application in the automotive industry.

- For instance, according to the International Organization of Motor Vehicle Manufacturers, the worldwide production of passenger cars reached up to 68,020,265 units in 2023, witnessing an increase of nearly 11% as compared to 2022.

Hence, according to the analysis, the rising automobile production is increasing the adoption of SMT equipment during the assembly of PCBs in automobile electronics systems, in turn boosting the surface mount technology equipment market opportunities during the forecast period.

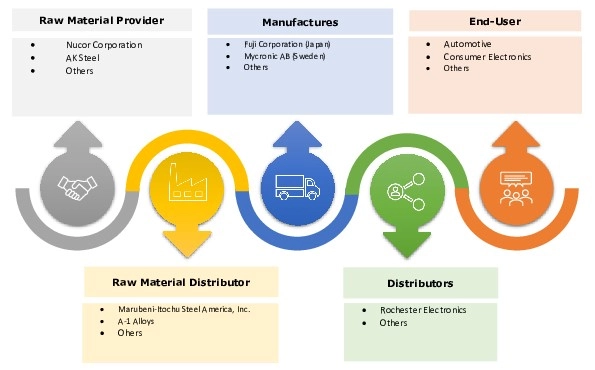

Top Key Players and Market Share Insights:

The global surface mount technology equipment market is highly competitive with major players providing services to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the surface mount technology equipment market. Key players in the surface mount technology equipment industry include-

- Yamaha Motor (Japan)

- Juki Corporation (Japan)

- ASM Assembly Systems (Germany)

- Hitachi High-Technologies Corporation (Japan)

- Panasonic Corporation (Japan)

- Viscom AG (Germany)

- Fuji Corporation (Japan)

- Mycronic AB (Sweden)

- Nordson Corporation (US)

- KLA Corporation (US)

- Saki Corporation (Japan)

Surface Mount Technology Equipment Market Segmental Analysis :

By Equipment:

Based on equipment, the market is segmented into inspection equipment, placement equipment, printer, and others.

Trends in the equipment:

- Factors including the growth trend in electronics sector, driven by the rising consumer demand for electronic devices, including smartphones, tablets, wearables, and others, are among the key trends driving the placement equipment segment.

- Factors including growing demand for consumer electronics, increasing adoption of safety and autonomous features in automobiles, and rising penetration of internet of things (IoT) in several industrial sectors are key trends driving the inspection equipment segment.

Placement equipment segment accounted for the largest revenue share in the total surface mount technology equipment market share in 2024.

- SMT placement equipment, also known as pick-and-place machine, refers to a type of automated equipment that is used for placing surface-mount components onto a printed circuit board.

- Placement equipment utilizes a robotic arm (pick and place head) that is designed for picking up components from feeders or supply trays and placing them onto specific locations on the printed circuit boards.

- Moreover, the utilization of placement equipment offers a range of benefits, including faster assembly speed, higher precision, consistency, and flexibility in operations, among others.

- For instance, in November 2023, SMTmax launched its QM-4044 model of an automatic pick and place machine that is designed for table-top or stand-alone usage. The new QM-4044 placement equipment offers a range of features, including innovative design, advanced vision system, high production rate, expansive feeder capacity, and improved customization to meet distinctive handling requirements and applications.

- According to the analysis, the rising innovations associated with SMT placement equipment are driving the surface mount technology equipment market trends.

The inspection equipment segment is anticipated to register the fastest CAGR growth during the forecast period.

- SMT inspection equipment refers to a type of equipment used during the inspection phase of SMT assembly lines.

- SMT inspection equipment is designed for examining printed circuit boards (PCBs) for defects and errors, which helps in saving time and reducing the risk of human error.

- Moreover, SMT inspection equipment utilizes high-resolution cameras and advanced image processing algorithms for detecting flaws such as missing components, soldering defects, component misalignment, bridging, and incorrect polarity.

- Additionally, SMT inspection equipment possesses the ability to inspect hidden and visible defects, and it is capable of efficiently capturing data in real-time, which enhances the speed and accuracy of the inspection process significantly.

- For instance, in March 2024, Yamaha Motor Co., Ltd. introduced its new YRi-V TypeHS hybrid automated optical inspection equipment, which is an SMT inspection equipment capable of attaining both high precision and high speed in operations for electronic component mounting factories. The YRi-V TypeHS inspection system offers enhanced image processing capability by utilizing a high-resolution camera, along with the latest high-performance GPU and CPU applications.

- Hence, the increasing advancements related to inspection equipment are anticipated to drive the market during the forecast period.

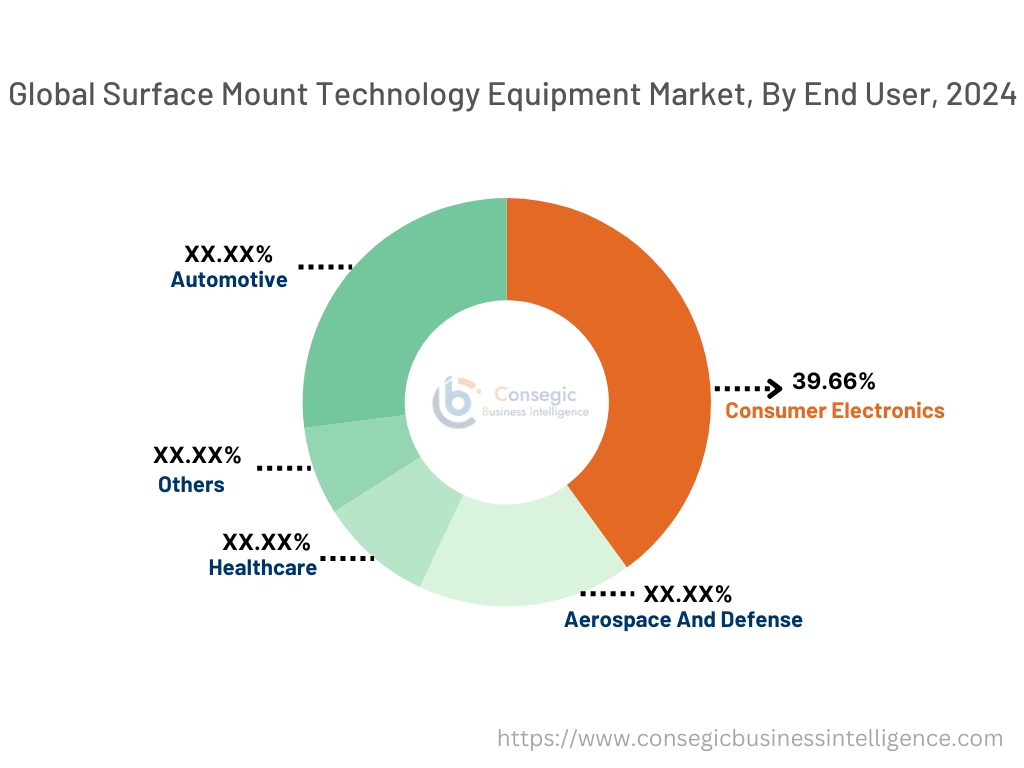

By End-User:

Based on the end-user, the market is segmented into automotive, consumer electronics, aerospace and defense, healthcare, and others.

Trends in the end-user:

- Factors including the rising penetration of smartphones, laptops, and other consumer devices integrated with advanced features, increasing popularity of wearable devices, and advancements in consumer electronics including IoT and AI are key trends driving the consumer electronics segment.

- Factors including the increasing production of automobiles, rising adoption of electric vehicles (EVs), advancements in autonomous driving systems, and growing integration of enhanced automobile infotainment, sensors, and safety solutions are primary trends driving the automotive segment.

The consumer electronics segment accounted for the largest revenue share of 39.66% in the surface mount technology equipment market share in 2024.

- SMT equipment is primarily used in the consumer electronics sector to place surface-mount electronic components onto a printed circuit board.

- Moreover, the utilization of SMT equipment offers a range of benefits, including facilitation of miniaturized components, increased automation, maximum flexibility in building PCBs, improved performance and reliability, reduced manual intervention for component placement, ease of PCB assembly, and others.

- The aforementioned benefits of SMT equipment are key determinants for increasing its application during PCB assembly in consumer electronics devices.

- For instance, according to the India Brand Equity Foundation, smartphone production in India witnessed considerable growth in India and the smartphone sector was valued at USD 49.55 billion in FY2023-24.

- According to the analysis, the above factors are driving the surface mount technology equipment market size.

The automotive segment is anticipated to register a substantial CAGR growth during the forecast period.

- SMT equipment is used in automotive sector, specifically during the assembly of PCBs in automobile electronics systems, including on-board vehicle control system, infotainment system, advanced driver assistance system, telematics system, and others.

- Moreover, SMT equipment enables quicker and accurate mounting of several electronic components on PCBs of automobile electronics systems, which helps in achieving improved system performance.

- For instance, according to the International Organization of Motor Vehicle Manufacturers, the total production of passenger cars in Europe reached up to 15,449,729 units in 2023, representing an increase of nearly 13% as compared to 2022.

- Thus, the rising automotive production is anticipated to boost the surface mount technology equipment market growth during the forecast period.

Surface Mount Technology Equipment Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 10,736.00 Million |

| CAGR (2025-2032) | 7.6% |

| By Equipment |

|

| By End-User |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

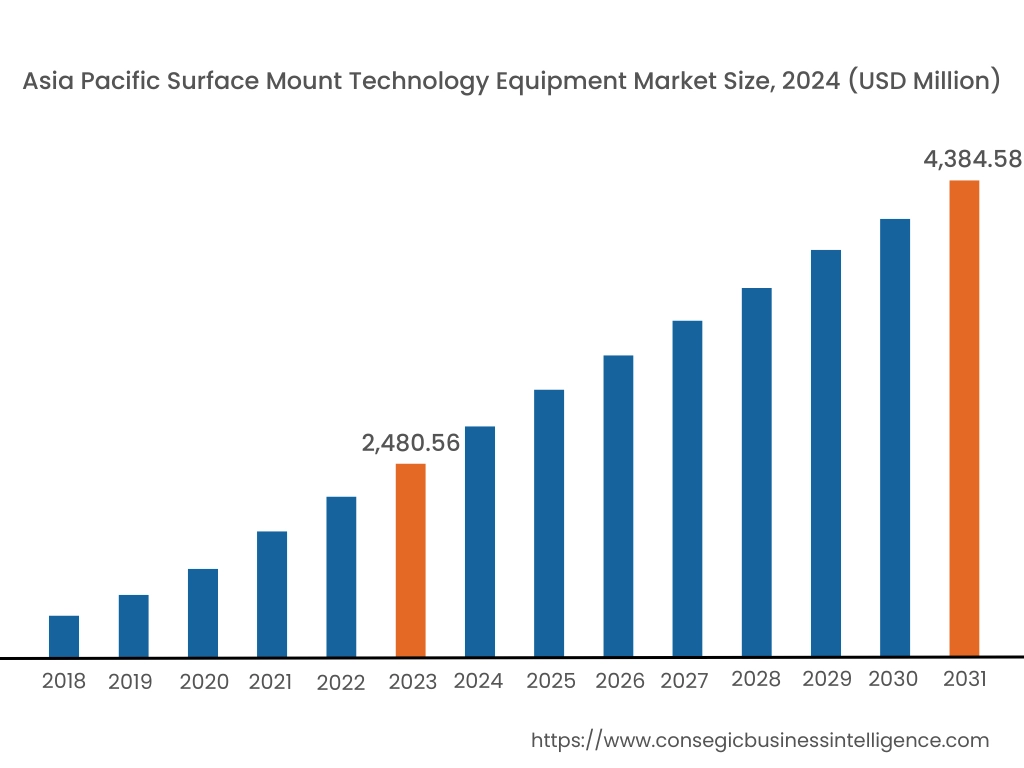

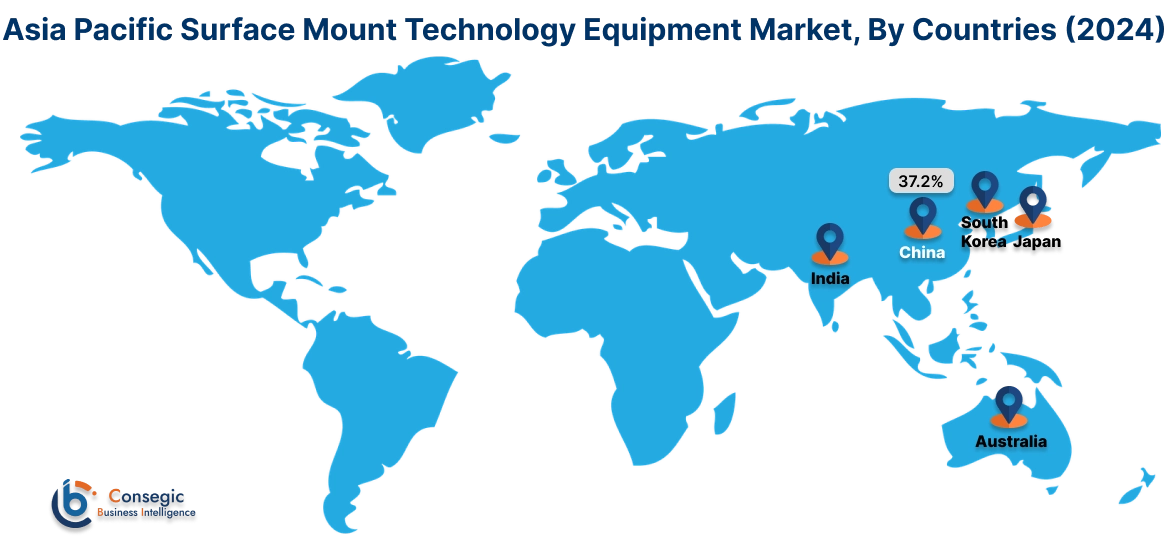

Regional Analysis:

The regions covered are North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

Asia Pacific region was valued at USD 2,480.56 Million in 2024. Moreover, it is projected to grow by USD 2,616.86 Million in 2025 and reach over USD 4,384.58 Million by 2032. Out of this, China accounted for the maximum revenue share of 37.2%. As per the surface mount technology equipment market analysis, the adoption of SMT equipment in the Asia-Pacific region is primarily driven by growing consumer electronics, automotive, and telecommunication sectors, among others. Additionally, the rising production of consumer electronic devices is further driving the surface mount technology equipment market expansion in the region.

- For instance, according to the India Brand Equity Foundation, the value of consumer electronics and appliances sector in India reached up to USD 9.84 billion in 2021, and it is estimated to grow at a substantial rate to reach USD 21.18 billion by 2025. Consequently, the above factors are further driving the market in the Asia-Pacific region.

North America is estimated to reach over USD 2,819.27 Million by 2032 from a value of USD 1,650.17 Million in 2024 and is projected to grow by USD 1,735.85 Million in 2025. In North America, the growth of surface mount technology equipment industry is driven by increasing investments in aerospace & defense, automotive, healthcare, and other industrial sectors. Similarly, the rising production of automobiles and aircraft is further contributing to the surface mount technology equipment market demand.

- For instance, according to the International Organization of Motor Vehicle Manufacturers, the total vehicle production in North America reached 16.16 million in 2023, representing an increase of 9.3% from 2022. The above factors are projected to drive the surface mount technology equipment market trends in North America during the forecast period.

Moreover, according to the regional analysis, factors including rising investments in electric vehicle manufacturing, increasing production of aircraft, and significant advancements in medical devices are driving the surface mount technology equipment market demand in Europe. In addition, as per the surface mount technology equipment market analysis, the market demand in Latin America, Middle East, and African regions is anticipated to grow at a significant rate due to factors such as increasing consumer electronics production, rising investments in aerospace & defense industry, and others.

Recent Industry Developments :

Product Launches:

- In May 2024, Europlacer launched its new generation of iineo pick and place machine. These dual-head and single-head SMT placement machines have been modernized and are available with 8 or 12 nozzles. The SMT placement machine performance is supported by a redesigned machine vision system that features very high-resolution cameras, which are mounted on the turret heads and the machine frame as a fixed upward-facing camera.

- In September 2023, Panasonic Corporation launched its new NPM-GP model of SMT screen printing machine in India to facilitate increased efficiency and precision in assembling printed circuit boards (PCBs). The new screen-printing machine features automatic printing process functions and assists in production processes with features such as automated model changeover and automated operations during production, and optimization of maintenance timing.

Key Questions Answered in the Report

How big is the surface mount technology equipment market? +

The surface mount technology equipment market was valued at USD 6,273.93 Million in 2024 and is projected to grow to USD 10,736.00 Million by 2032.

Which is the fastest-growing region in the surface mount technology equipment market? +

Asia-Pacific is the region experiencing the most rapid growth in the surface mount technology equipment market.

What specific segmentation details are covered in the surface mount technology equipment report? +

The surface mount technology equipment report includes specific segmentation details for equipment, end-user, and region.

Who are the major players in the surface mount technology equipment market? +

The key participants in the surface mount technology equipment market are Yamaha Motor (Japan), Juki Corporation (Japan), Viscom AG (Germany), Fuji Corporation (Japan), Mycronic AB (Sweden), Nordson Corporation (US), KLA Corporation (US), Saki Corporation (Japan), ASM Assembly Systems (Germany), Hitachi High-Technologies Corporation (Japan), and Panasonic Corporation (Japan).