Aluminium Forging Market Size:

Aluminium Forging Market Size is estimated to reach over USD 21.96 Billion by 2032 from a value of USD 13.54 Billion in 2024 and is projected to grow by USD 14.39 Billion in 2025, growing at a CAGR of 6.4% from 2025 to 2032.

Aluminium Forging Market Scope & Overview:

Aluminum forging refers to a process that involves placing aluminum alloys under pressure for creating high-strength and durable parts. The aluminium forging process primarily involves pressing, squeezing, and pounding an aluminum billet under high pressure to produce robust parts with high strength. Moreover, it is a widely used manufacturing process across industries, such as automotive, oil and gas, aerospace and defense, and construction, among others. Additionally, this process involves heating aluminium to its recrystallization temperature, typically between 350°C and 500°C (662°F and 932°F).

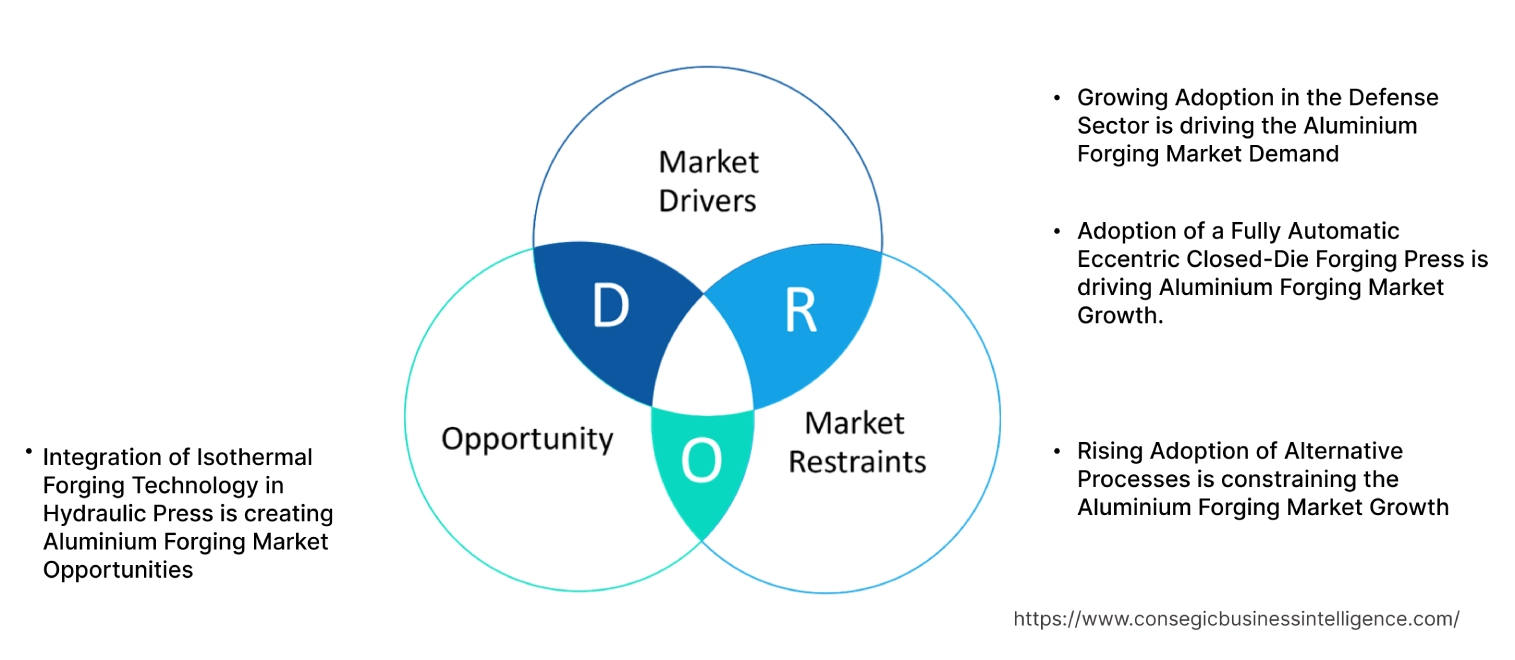

Aluminium Forging Market Dynamics - (DRO) :

Key Drivers:

Increasing need in the aerospace and defense industries is driving the aluminium forging market expansion

The aerospace & defense sector plays a crucial role in the growth of the aluminum forging market. Military sectors require high-performance materials that can survive extreme conditions and provide safety and reliability. Aluminum forgings meet these requirements, making them an ideal choice for manufacturing various defense components such as missile bodies, aircraft parts, and naval vessels. The continuous advancements in defense technologies and rising defense budgets across several countries are driving the need for aluminum forgings in this sector.

- For instance, in 2023, according to the Press Information Bureau of India, India's defense production reached USD 14.9 billion, representing a substantial increase of 16.7% as compared to 2022.

Therefore, according to the aluminium forging market analysis, the increasing need in the aerospace and defense is driving the aluminium forging market size and trends.

Key Restraints :

Fluctuating prices of raw materials and availability of alternatives are affecting the aluminium forging market demand

The aluminum industry is vulnerable to price volatility due to factors such as changes in global demand, trade policies, and supply chain disruptions. Additionally, the market faces competition from alternative materials, such as composites and advanced polymers, which offer similar performance characteristics and applications across various industries such as automotive, aerospace & defense, oil & gas, and others. Therefore, the aforementioned factors would further impact the aluminium forging market growth.

Future Opportunities :

Increasing adoption of electric vehicles (EVs) is expected to drive the aluminium forging market opportunities

With the global shift towards sustainable transportation and the growing need for electric vehicles, manufacturers are focusing on reducing vehicle weight to improve range and efficiency. Aluminum forgings offer an excellent solution, providing high-strength components while reducing overall vehicle weight. This trend creates a substantial opportunity for market players to develop innovative forging solutions tailored to the specific needs of the EV industry. The ongoing advancements in forging technologies and aluminum alloys are expected to further enhance the capabilities of forged components, in turn driving their adoption in the EV market.

- For instance, in January 2023, Pacific Precision Forgings significantly upgraded its aluminum forging capabilities by investing in a fully automatic, closed-die eccentric forging press. This strategic move aims to improve the quality of their products and contribute to the automotive sector's demand for lighter components. This strategic development is expected to boost the aluminium forging market share.

Thus, based on the above aluminium forging market analysis, the aforementioned factors are expected to drive the aluminium forging market opportunities.

Aluminium Forging Market Segmental Analysis :

By Forging Type:

Based on forging type, the aluminium forging market is segmented into open-die forging, closed-die forging, spin forging, ring rolled forging, and others.

Trends in the forging type:

- As industries continue to demand high-performance materials, the versatility and reliability of aluminum forgings will remain a key factor in their widespread adoption across various applications.

- The availability of these diverse aluminium forging options allows manufacturers to select the most suitable method for their specific requirements, thereby optimizing production efficiency and cost-effectiveness, further driving the aluminium forging market growth.

- Thus, based on the above analysis, these factors are driving the aluminium forging market demand and trends.

The closed-die forging segment accounted for the largest revenue share in the year 2024.

- Closed-die aluminium forgings, also known as impression die forgings, are extensively used due to their ability to produce complex shapes with high precision and minimal material waste.

- The closed die process enables tight tolerances and improved surface finish, which are essential for components that require precision and reliability.

- The growing demand for precision-engineered components in various industries is expected to drive the growth of the closed-die aluminum forgings segment.

- For instance, in 2024, Balu Forge announced the development of a new closed-die forging facility with an annual capacity of 72,000 tons. This development involves the addition of three new production lines, a 16-ton, 8,000-ton, and 10-ton closed-die forging hammer.

- Consequently, based on the above analysis, these factors are further driving the trends.

The ring rolled forging segment is anticipated to register the fastest CAGR growth during the forecast period.

- Rolled ring forgings are a specific type of forgings that are used to produce seamless rings with superior mechanical properties and structural integrity.

- These forgings are typically used in applications that require high resistance to fatigue and stress, such as aerospace engine parts, bearings, and gears.

- The ability of rolled ring forgings to withstand extreme temperatures and pressures makes them an ideal choice for critical applications, further driving their adoption in the market.

- Thus, based on the above analysis, these factors are expected to drive the aluminium forging market share and trends during the forecast period.

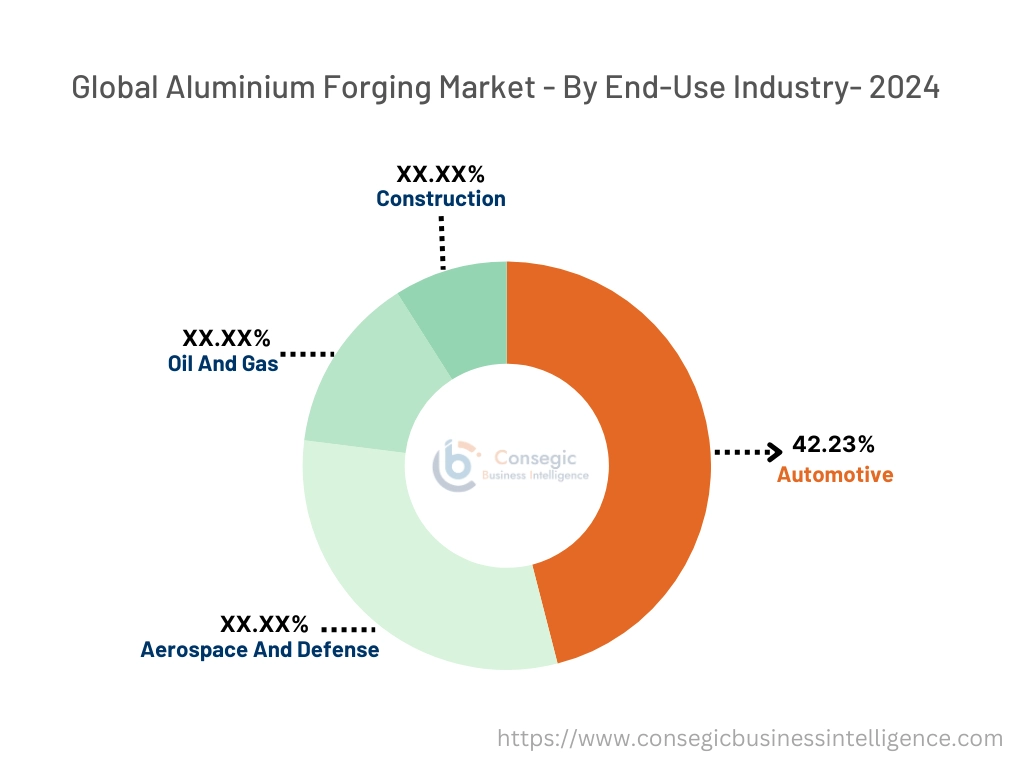

By End-Use Industry:

Based on end use, the aluminium forging market is segmented into automotive, oil and gas, aerospace and defense, construction, and others.

Trends in the application:

- The ongoing advancements in forging technologies and development of new alloys are expected to enhance the performance and capabilities of forged aluminum components, further driving their adoption across different application areas.

- The growing demand for infrastructure development and industrial machinery in emerging economies is also expected to drive the development of the segment.

- Based on the above analysis, these factors are anticipated to further drive the aluminium forging market trends during the forecast period.

The automotive segment accounted for the largest revenue share of 42.23% in the year 2024, and it is expected to register the highest CAGR growth during the forecast period.

- In the automotive sector, aluminum forgings are gaining traction due to their ability to reduce vehicle weight, enhance fuel efficiency, and comply with stringent emission regulations.

- Forged aluminum components are used in various automotive applications, including suspension systems, powertrain components, and wheels.

- The growing trend towards electric vehicles (EVs) is further boosting the need for lightweight materials, as manufacturers seek to improve the range and performance of EVs.

- Thus, based on the above analysis, these developments would further drive the aluminium forging market trends.

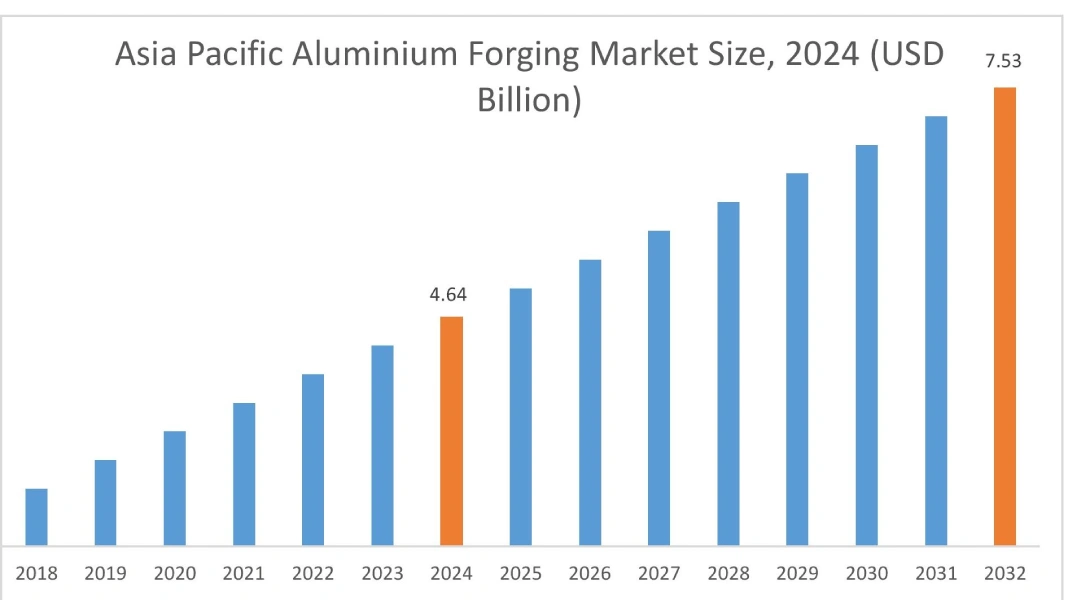

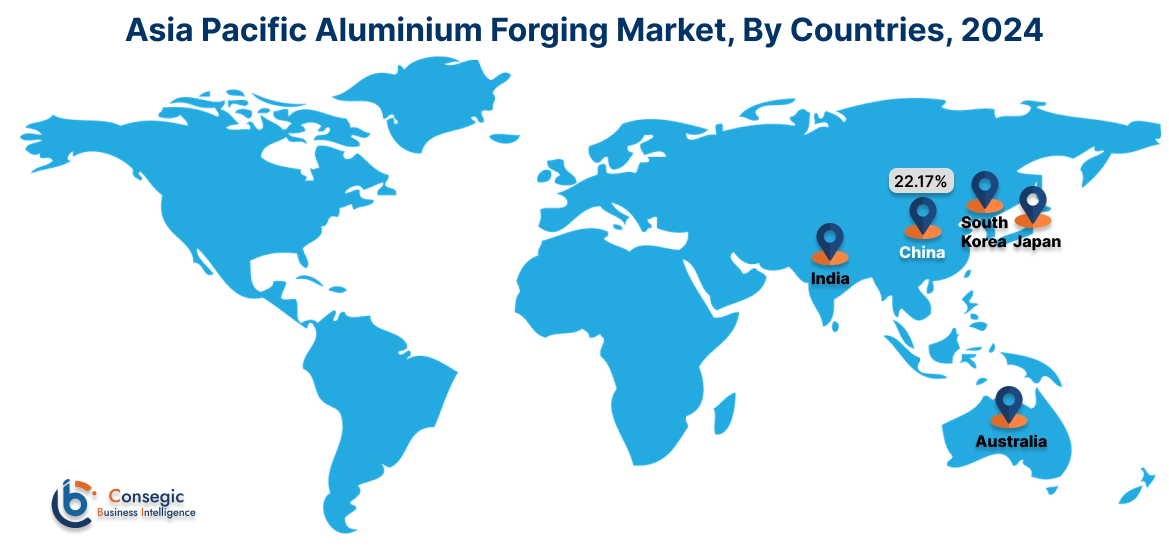

Regional Analysis:

The global market has been classified by region into North America, Europe, Asia-Pacific, Middle East & Africa, and Latin America.

Asia Pacific aluminium forging market expansion is estimated to reach over USD 7.53 billion by 2032 from a value of USD 4.64 billion in 2024 and is projected to grow by USD 4.99 billion in 2025. Out of this, the China market accounted for the maximum revenue split of 22.17%. The region's development is primarily driven by rapid industrialization, urbanization, and infrastructure development in countries like China and India. Further, the expanding automotive and construction industries, along with the growing aerospace sector are creating significant prospects for market growth in this region. Additionally, the increasing focus on renewable energy projects is driving the need for aluminum forgings in the energy sector. These factors would further drive the regional aluminium forging market during the forecast period.

- For instance, in February 2024, NTPC and NALCO (National Aluminium Company Limited) have partnered to expand aluminium production in Odisha, India. This collaboration aims to ensure a stable supply of high-quality aluminium, which will further drive growth in key industries such as automotive, construction, and aerospace & defense, among others.

North America is expected to witness the fastest CAGR of 6.9% during the forecast period, 2025-2032. North America holds a significant share of the market, owing to its advanced aerospace and automotive industries. The region's focus on technological innovation and the presence of major aerospace and automotive manufacturers contribute to the need for aluminum forgings. The United States plays a crucial role in the regional market, with its growing emphasis on modernizing defense equipment and expanding commercial aircraft production. Further, the regional market is projected to grow steadily, supported by ongoing investments in aerospace and defense technologies. These factors would further drive the regional market during the forecast period.

Additionally, according to the analysis, the aluminium forging industry in Europe is expected to witness significant development during the forecast period. The region's stringent emission regulations and commitment to sustainability are driving the need for aluminum forgings in the automotive sector. Additionally, countries in Latin America are leading the aluminum market, primarily due to their strong automotive and industrial sectors. The development of their automotive market is a major factor, driving increased need for aluminum forged components in various vehicle parts such as engine blocks, suspension systems, and wheel rims. Further, the oil and gas sector in the Middle East & Africa region heavily relies on aluminum forged components, as these components are essential for applications that involve high temperatures and pressures, such as valves, fittings, and pumps, where their durability and robust performance are critical. These factors are driving the regional aluminium forging market size and share.

Top Key Players and Market Share Insights:

The global aluminium forging market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the aluminium forging industry include-

- Alcoa Corporation (U.S.)

- Precision Castparts Corp. (U.S.)

- VSMPO-AVISMA Corporation (Russia)

- ATI Inc. (U.S.)

- Farinia Group (France)

- Kobe Steel, Ltd. (Japan)

- Bharat Forge Limited (India)

- Arconic Inc. (U.S.)

- Aichi Steel Corporation (Japan)

- Thyssenkrupp AG (Germany)

Recent Industry Developments :

Expansion:

- In September 2024, Ramkrishna Forgings established a new aluminum forging plant in Jamshedpur, India, investing USD 6.78 million in the venture. Additionally, this facility is projected to have an annual capacity of 3,000 tonnes and is set to begin operations by the second quarter of the 2025-26 fiscal year.

Aluminium Forging Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 (USD Million) | USD 21.96 Billion |

| CAGR (2025-2032) | 6.4% |

| By Forging Type |

|

| By End-Use Industry |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Aluminium Forging Market? +

Aluminium Forging market size is estimated to reach over USD 21.96 Billion by 2032 from a value of USD 13.54 Billion in 2024 and is projected to grow by USD 14.39 Billion in 2025, growing at a CAGR of 6.4% from 2025 to 2032.

Which is the fastest-growing region in the Aluminium Forging Market? +

Asia-Pacific region is experiencing the most rapid growth in the market.

What specific segmentation details are covered in the aluminium forging report? +

The aluminium forging report includes specific segmentation details for forging type, end user, and region.

Who are the major players in the Aluminium Forging Market? +

The key participants in the market are Alcoa Corporation (U.S.), Precision Castparts Corp. (U.S.), Kobe Steel, Ltd. (Japan), Bharat Forge Limited (India), Arconic Inc. (U.S.), Aichi Steel Corporation (Japan), Thyssenkrupp AG (Germany), VSMPO-AVISMA Corporation (Russia), ATI Inc. (U.S.), Farinia Group (France), and others.