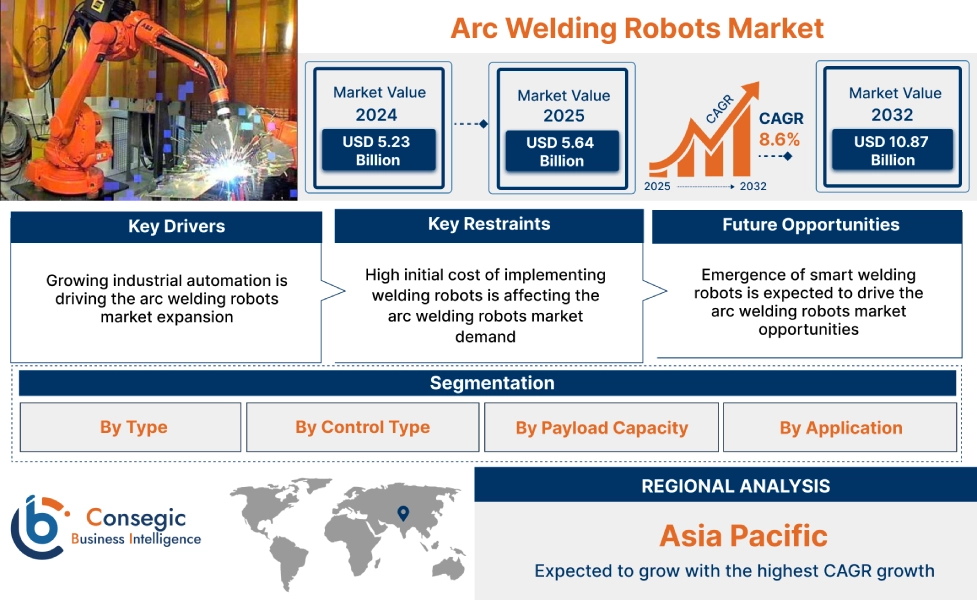

Arc Welding Robots Market Size:

Arc Welding Robots Market Size is estimated to reach over USD 10.87 Billion by 2032 from a value of USD 5.23 Billion in 2024 and is projected to grow by USD 5.64 Billion in 2025, growing at a CAGR of 8.6% from 2025 to 2032.

Arc Welding Robots Market Scope & Overview:

Arc welding robots are automated systems that use robots to perform arc welding, a process where an electric arc is used to melt metal and join it together. These systems combine a robot arm with a welding power source, torch, and often wire feeder, all controlled by a computer. The robot precisely moves the welding torch along the weld path, ensuring consistent weld quality and speed.

How is AI Transforming the Arc Welding Robots Market?

AI is transforming the global arc welding robots market by enhancing precision, efficiency, and adaptability in manufacturing processes. Through the use of machine learning, AI enables robots to automatically adjust welding parameters based on material type, thickness, and joint variations, reducing defects and rework. AI-powered vision systems help detect misalignments and ensure accurate weld positioning in real time. Predictive maintenance, supported by AI, minimizes downtime by identifying potential equipment failures early. In addition, AI-driven robots can learn from past operations to continuously improve weld quality and adapt to complex designs. As industries like automotive, aerospace, and construction demand higher productivity and consistency, AI integration is driving innovation and broader adoption of arc welding robots globally.

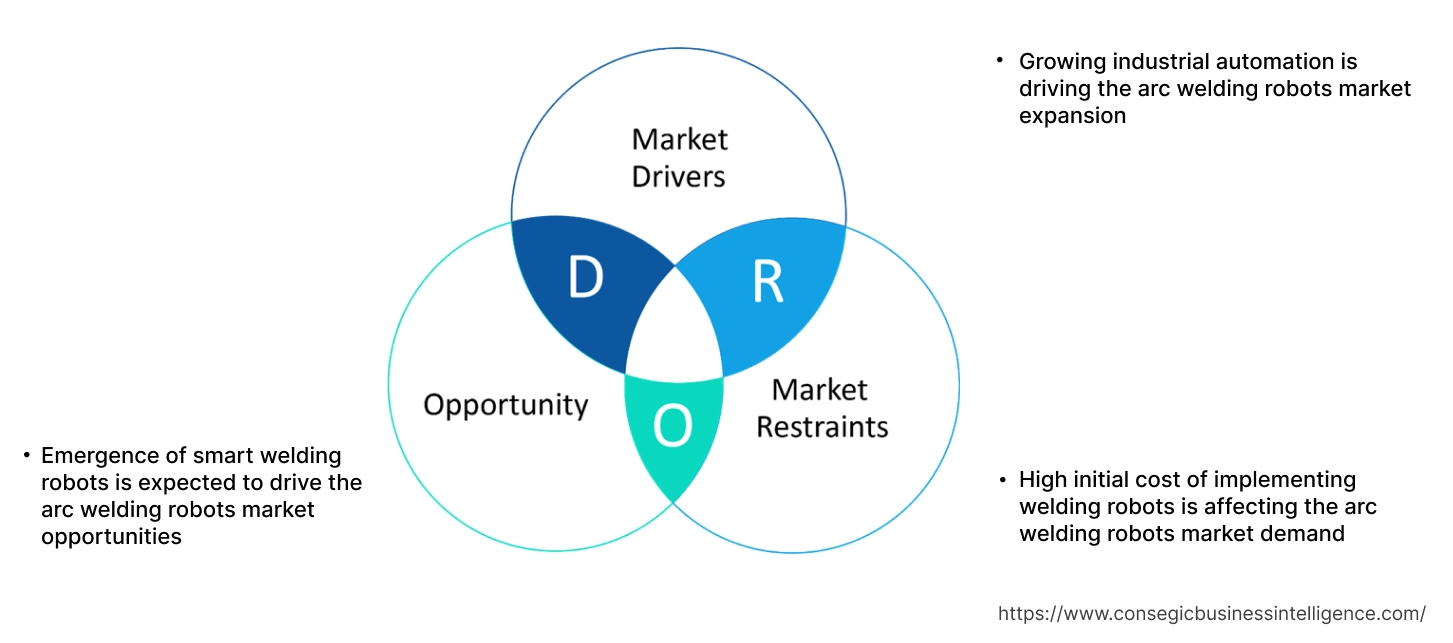

Arc Welding Robots Market Dynamics - (DRO) :

Key Drivers:

Growing industrial automation is driving the arc welding robots market expansion

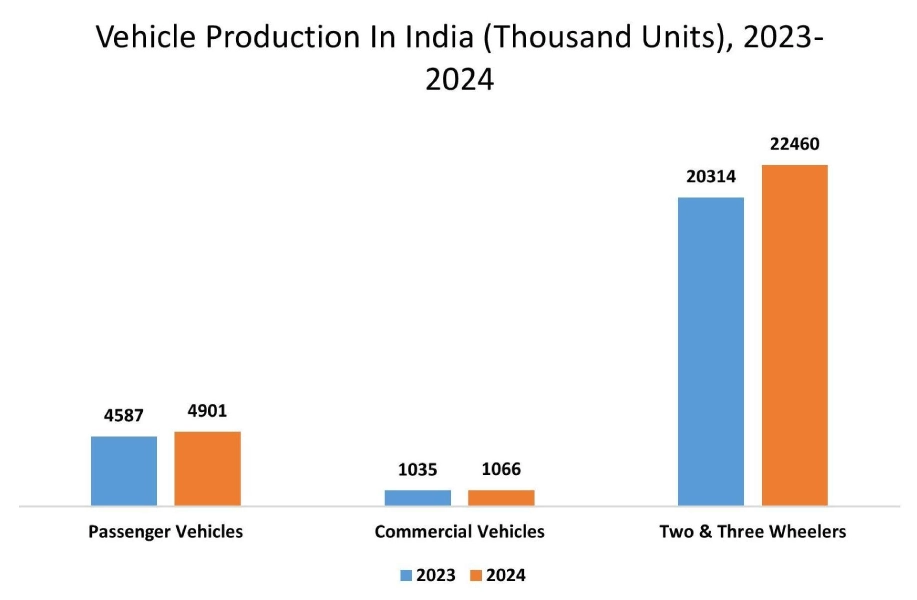

The increasing adoption of industrial automation is significantly fueling the demand for arc welding robots. As industries globally embrace automation to enhance efficiency and reduce expenses, these robots are becoming crucial in streamlining welding operations. The automotive sector perfectly demonstrates how industrial automation propels the need for arc welding robots. Car manufacturers are integrating robotic welding technologies into their production lines to guarantee consistent, high-quality welds. Further, prominent automakers utilize arc welding robots for assembling car bodies, ensuring accuracy and adherence to design specifications.

Further, the automotive sector has been a major adopter of robots, with welding being a particularly common application. The need for efficient and accurate welding in the manufacturing of vehicle parts is a key factor driving the automotive sector's integration of arc welding robots.

- For instance, according to the International Federation of Robotics (IFR), the global market for industrial robots witnessed a 7% increase, reaching over 590,000 units in the year 2023.

- Additionally, according to the Robotic Industries Association (RIA), automotive original equipment manufacturers (OEMs) and their suppliers acquired 15,723 robots in 2023, representing over half of all robot purchases.

Thus, according to the arc welding robots market analysis, the growing industrial automation is driving the arc welding robots market size and growth.

Key Restraints:

High initial cost of implementing welding robots is affecting the arc welding robots market demand

The high initial cost of implementing welding robots is a significant barrier for small and medium-sized enterprises (SMEs). The substantial investment required for purchasing and installing advanced welding robots, along with the need for skilled personnel to operate and maintain them, can be a constraint for many potential users.

Additionally, the ongoing advancements in welding technologies necessitate continuous upgrades and investments, which can be financially difficult for certain companies. Thus, the aforementioned factors would further impact the arc welding robots market size.

Future Opportunities :

Emergence of smart welding robots is expected to drive the arc welding robots market opportunities

The emergence of smart welding robots marks a significant evolution in the global market, transforming how the welding processes are executed in manufacturing settings. Smart welding robots are equipped with advanced sensors, data analytics capabilities, and connectivity features that enable real-time monitoring, analysis, and optimization of welding operations. These robots can autonomously adjust welding parameters, such as voltage, current, and wire feed speed, based on environmental conditions and material characteristics, ensuring optimal weld quality and efficiency.

These robots can communicate and share data with other connected devices and systems, such as robotic arms, sensors, and cloud-based platforms, facilitating real-time decision-making and process optimization. Through the integration of smart welding robots into interconnected production workflows, manufacturers can achieve greater flexibility, agility, and responsiveness to changing market needs, thereby gaining a competitive edge in the global manufacturing landscape.

- For instance, FANUC’ssmart welding robots are designed to boost output, improve weld quality, and cut expenses. These robots aim to deliver better outcomes while also making the workplace safer.

Thus, based on the above arc welding robots market analysis, the emergence of smart welding robots is expected to drive the arc welding robots market opportunities and growth.

Arc Welding Robots Market Segmental Analysis :

By Type:

Based on type, the market is segmented into non-consumable electrode and consumable electrode.

Trends in the type:

- Modern arc welding robots increasingly incorporate sensors like touch sensing, laser seam tracking, and vision systems. These sensors enable real-time adjustments to welding parameters and robot paths to compensate for part variations, improve weld quality, and reduce errors.

- Advanced systems can acquire and analyze operational data during the welding process. This allows for real-time quality validation and continuous process optimization.

- Thus, based on the above analysis, these factors are driving the arc welding robots market demand and trends.

The non-consumable electrode segment accounted for the largest revenue in the year 2024.

- Non-consumable electrode arc welding utilizes an electrode that does not melt and become part of the weld. The most common type of non-consumable electrode welding used with robots is gas tungsten arc welding (GTAW).

- The technological advancements in GTAW robots, such as the integration of advanced control systems and sensors, are enhancing their performance and expanding their application scope.

- GTAW robots are preferred in industries such as aerospace and electronics, where the fabrication of intricate and delicate parts is essential.

- Thus, based on the above analysis, these factors are further driving the arc welding robots market growth.

The consumable electrode segment is anticipated to register the fastest CAGR during the forecast period.

- Consumable electrode arc welding robots utilize a welding process where the electrode melts and becomes part of the weld. The most common types of consumable electrode welding used with robots are gas metal arc welding (GMAW).

- GMAW robots are extensively employed in industries such as automotive and shipbuilding, where high productivity and consistent weld quality are crucial.

- The increasing need for automated GMAW robots is driven by their ability to handle a wide range of materials and thicknesses, making them suitable for various welding tasks.

- Thus, based on the above analysis and developments, these factors are expected to drive the arc welding robots market share and growth during the forecast period.

By Control Type:

Based on the control type, the market is segmented into manual and automatic.

Trends in the control type:

- There is a growing focus on developing more intuitive and user-friendly programming interfaces, including offline programming (OLP) with advanced simulation capabilities and teach pendants with enhanced graphical displays. This aims to simplify robot programming and reduce setup times.

- Robots with higher accuracy, repeatability, and smoother motion controlare being developed to ensure precise weld bead placement and consistent weld quality, particularly for complex 3D geometries.

The manual segment accounted for the largest revenue in the year 2024.

- The development of more user-friendly interfaces with advanced visualization and control options that allow welders to guide robots easily for complex, non-repetitive tasks is driving the segment. This could involve augmented reality overlays or more direct manipulation interfaces.

- Manual guidance interfaces could potentially be used as advanced training tools, allowing experienced welders to demonstrate techniques that can then be recorded and potentially translated into automated programs.

- Thus, based on the above analysis, these factors would further supplement the arc welding robots market

The automatic segment is anticipated to register the fastest CAGR during the forecast period.

- Robots are increasingly using AI and ML to analyze vast amounts of welding data, optimize welding parameters in real-time, predict potential defects, and even perform self-correction during the welding process.

- The integration of sophisticated sensors such as 3D vision systems, laser scanners, and tactile sensors enables robots to identify and track weld joints accurately, adapt to variations in part fit-up, and perform in-process quality checks.

- Robots are being adapted for advanced welding processes such as laser welding, electron beam welding, and hybrid welding to handle dissimilar materials and complex geometries prevalent in industries including aerospace and electric vehicles.

- For instance, Kawasaki BA006L is an automatic arc welding robot with a hollow wrist, and it protects cables, improves wire feeding stability, and simplifies programming. It is capable of handling various welding processes (MIG/MAG, TIG, and others) with easy tool changes.

- These developments in the automatic control segment are anticipated to further drive the arc welding robotsmarket trends during the forecast period.

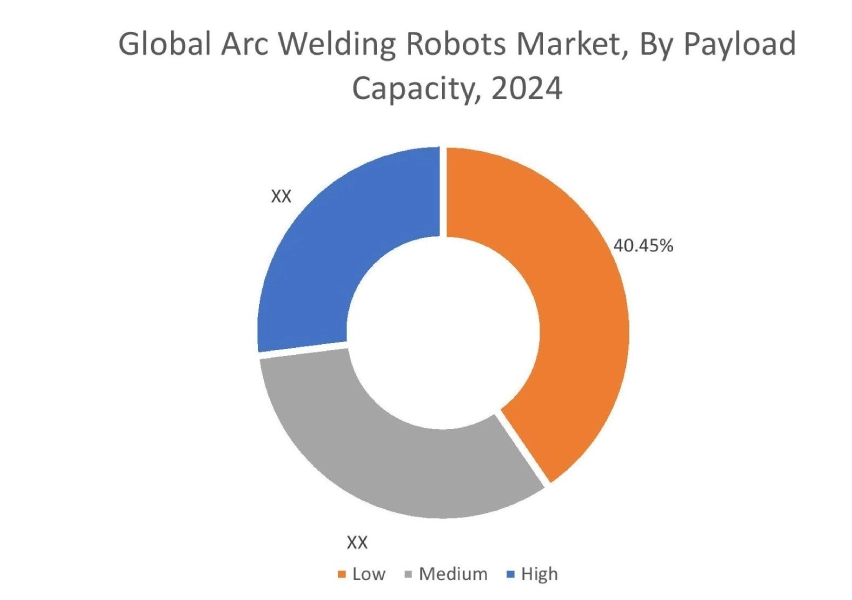

By Payload Capacity:

Based on payload capacity, the market is segmented into low, medium, and high.

Trends in the payload capacity:

- The ability to offer a wide range of welding robots with varying payload capacities enables manufacturers to address the diverse welding requirements of their customers, thereby driving market growth.

- The development of advanced medium and heavy-duty welding robots with features such as real-time monitoring and adaptive control is enhancing their performance and expanding their application scope.

The low segment accounted for the largest revenue share of 40.45% in the year 2024.

- Robots with a low payload capacity are generally used for light-duty welding applications that require high precision and flexibility.

- These robots are extensively employed in the electronics and electrical industries, where the welding of small and delicate components is essential.

- The increasing demand for miniaturized and high-precision welding solutions in these industries is driving the adoption of light-duty welding robots.

- Additionally, the development of compact and lightweight welding robots with advanced control systems is further boosting the segment growth.

- Therefore, the aforementioned factors are driving the arc welding robots market growth.

The medium segment is anticipated to register the fastest CAGR during the forecast period.

- Robots with a medium payload capacity are used for medium-duty welding applications that require a balance between precision and strength.

- These robots are widely employed in the automotive and aerospace industries, where the welding of medium-sized components and structures is common.

- The ability of medium-duty welding robots to handle a variety of welding tasks with high accuracy and efficiency is driving their adoption in these sectors.

- Moreover, the increasing focus on improving production efficiency and reducing operational costs is further propelling the demand for medium-duty welding robots.

- These factors are anticipated to further drive the arc welding robots market trends during the forecast period.

By Application:

Based on application, the market is segmented into metal and mining, automotive, shipbuilding, construction, heavy equipment, aerospace & defense, electronics, and others.

Trends in the application:

- By automating welding processes, manufacturers can improve operational efficiency, enhance product quality, and reduce lead times, thereby gaining a competitive edge in the global market.

- The development of compact and lightweight welding robots with advanced control systems is boosting the segment growth.

The automotive segment accounted for the largest revenue in the year 2024, and it is expected to register the highest CAGR during the forecast period.

- The automotive sector is one of the largest end-users of industrial welding robots, driven by the need for high precision, speed, and consistency in welding automotive components and structures.

- The increasing demand for automated welding solutions in the automotive industry is propelled by the growing focus on improving production efficiency, reducing operational costs, and ensuring high-quality welds.

- Moreover, the development of electric and autonomous vehiclesis further boosting the demand for advanced welding robots in the automotive sector.

- Thus, the above factors are driving the global market trends.

Regional Analysis:

The global market has been classified by region into North America, Europe, Asia-Pacific, Middle East & Africa, and Latin America.

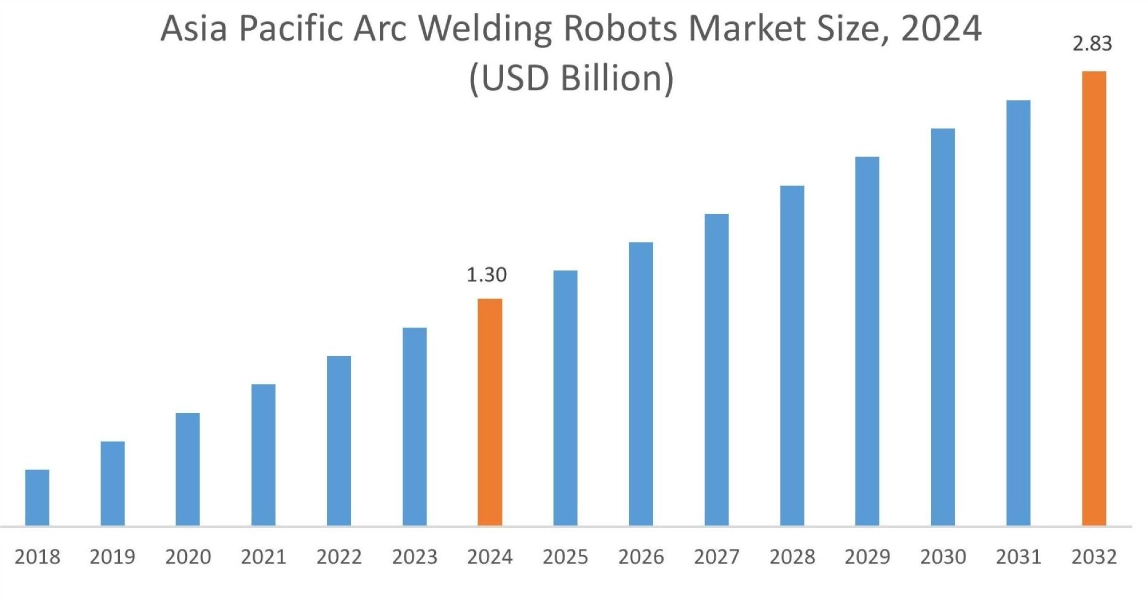

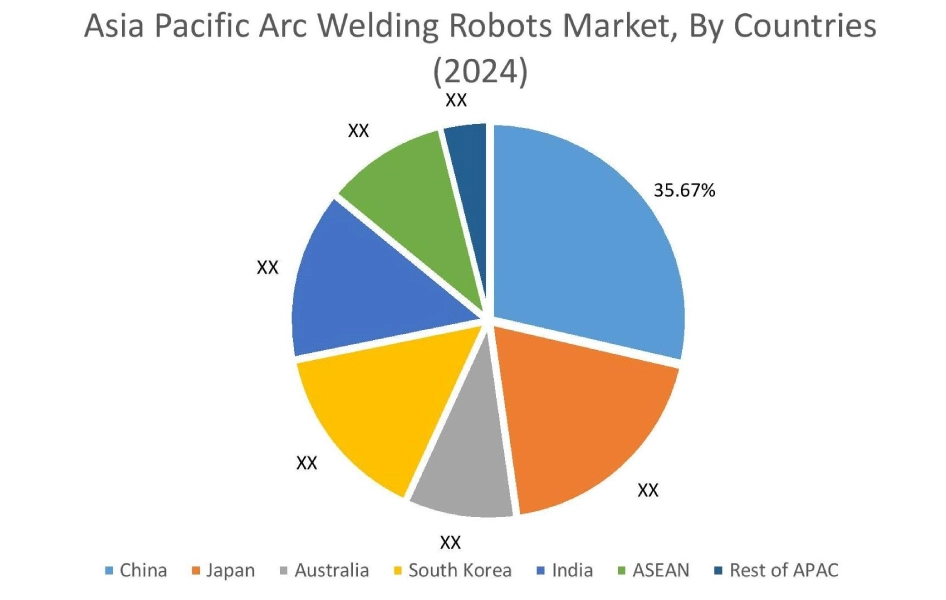

Asia Pacific arc welding robots market expansion is estimated to reach over USD 2.83 billion by 2032 from a value of USD 1.30 billion in 2024 and is projected to grow by USD 1.41 billion in 2025. Out of this, the China market accounted for the maximum revenue split of 35.67%. The regional market presents significant opportunities driven by the continuous advancements in robotics and welding technologies. The integration of artificial intelligence (AI), machine learning, and the internet of things (IoT) into welding robots is creating new prospects for innovation and efficiency in welding processes. These technologies enable welding robots to perform complex tasks with higher accuracy and adaptability, catering to the growing need for customized and flexible manufacturing solutions. Furthermore, the development of compact and lightweight welding robots is expanding their application scope, particularly in small and medium-sized enterprises (SMEs), thereby driving the market development. These factors would further drive the regional arc welding robots market during the forecast period.

- For instance, Kawasaki Robotics offers a complete, ready-to-use arc welding robot system called K-ARC. This solution is built around their BA006N arc welding robot and includes other premium components.

The North America market is estimated to reach over USD 4.20 billion by 2032 from a value of USD 2.03 billion in 2024 and is projected to grow by USD 2.19 billion in 2025. North America holds a significant share in the global welding robots market, propelled by the advanced manufacturing sectors in the United States and Canada. With a focus on innovation and technology adoption, coupled with a strong emphasis on productivity and quality, industries in North America are increasingly turning to industrial welding robots to streamline operations, reduce labor costs, and enhance production efficiency. Additionally, the presence of key players in the robotics industry contributes to the region's significant market share. These factors would further drive the market in North America.

- For instance, in May 2021, Lincoln Electriclaunched its new HELIX M627 Orbit GTAW welding heads. These heads are field-tested and designed to be innovative and easy to use, allowing customers to readily benefit from the increased efficiency and high-quality welds offered by mechanized GTAW.

According to the analysis, the arc welding robots industry in Europe is anticipated to witness significant development during the forecast period. Europe's highly developed manufacturing infrastructure, stringent quality standards, and emphasis on automation and efficiency contribute to the adoption of industrial welding robots across various industries, including automotive, aerospace, and electronics. Additionally, industries in Latin America are increasingly adopting industrial welding robots to streamline their production processes, reduce downtime, and minimize defects. Further, as the manufacturing sector in the Middle East & African countries flourishes due to economic development and government encouragement of local production, the need for welding robots is expected to grow in the upcoming years.

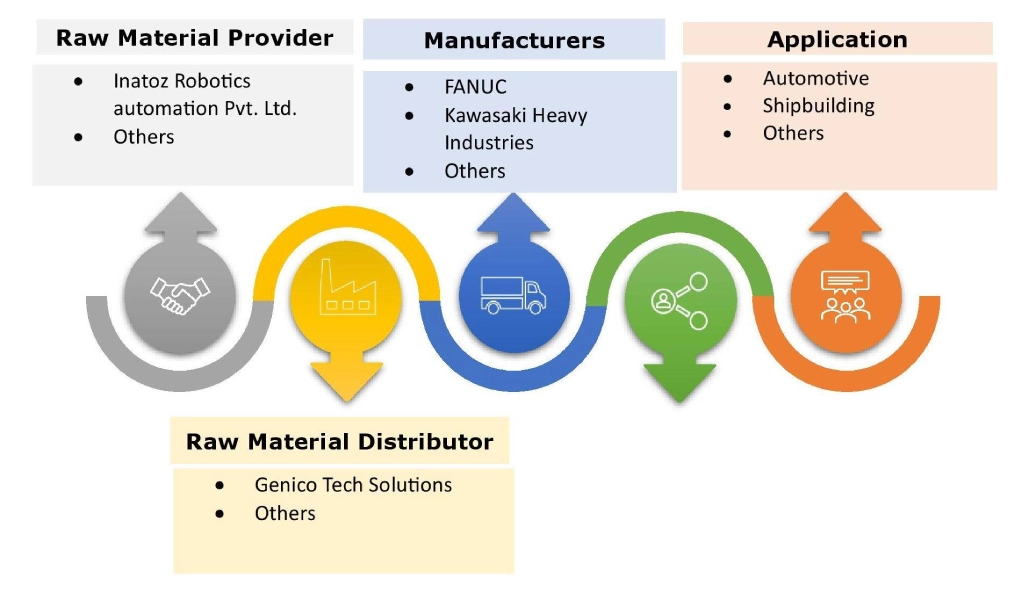

Top Key Players and Market Share Insights:

The global arc welding robots market is highly competitive, with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D), product innovation, and end-user launches to hold a strong position in the market. Key players in the arc welding robots industry include-

- ABB (Switzerland)

- Toyota (Japan)

- Epson Robots (Japan)

- Rockwell Automation (U.S.)

- Comau (Italy)

- FANUC (Japan)

- Kawasaki Heavy Industries (Japan)

- Midea (China)

- Yaskawa (Japan)

- Lincoln Electric (U.S.)

Arc Welding Robots Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 10.87 Billion |

| CAGR (2025-2032) | 8.6% |

| By Type |

|

| By Control Type |

|

| By Payload Capacity |

|

| By Application |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Arc Welding Robots Market? +

Arc Welding Robots market size is estimated to reach over USD 10.87 Billion by 2032 from a value of USD 5.23 Billion in 2024 and is projected to grow by USD 5.64 Billion in 2025, growing at a CAGR of 8.6% from 2025 to 2032.

Which is the fastest-growing region in the Arc Welding Robots Market? +

Asia-Pacific region is experiencing the most rapid growth in the market.

What specific segmentation details are covered in the Arc Welding Robots report? +

The arc welding robots report includes specific segmentation details for type, control type, payload capacity, application, and region.

Who are the major players in the Arc Welding Robots Market? +

The key participants in the market are ABB (Switzerland), FANUC (Japan), Kawasaki Heavy Industries (Japan), Midea (China), Yaskawa (Japan), Lincoln Electric (U.S.), Toyota (Japan), Epson Robots (Japan), Rockwell Automation (U.S.), Comau (Italy), and others.