Automotive Adhesives Market Size:

Automotive Adhesives Market size is growing with a CAGR of 7.1% during the forecast period (2025-2032), and the market is projected to be valued at USD 11.52 Billion by 2032 from USD 6.65 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 7.10 Billion.

Automotive Adhesives Market Scope & Overview:

Automotive adhesives are bonding agents. They are designed to join various materials during vehicle manufacturing. This includes metals, plastics, composites, and glass among others. They are generally advantageous in replacing traditional fasteners such as welds, bolts, rivets, and others. This helps with the construction of lighter vehicles and improved structural integrity. These adhesives are manufactured by blending different chemical resins. This includes polyurethanes, epoxies, acrylics, and silicone among others. These agents provide multiple advantages such as resistance to extreme temperatures, high chemical resistance, and excellent corrosion protection.

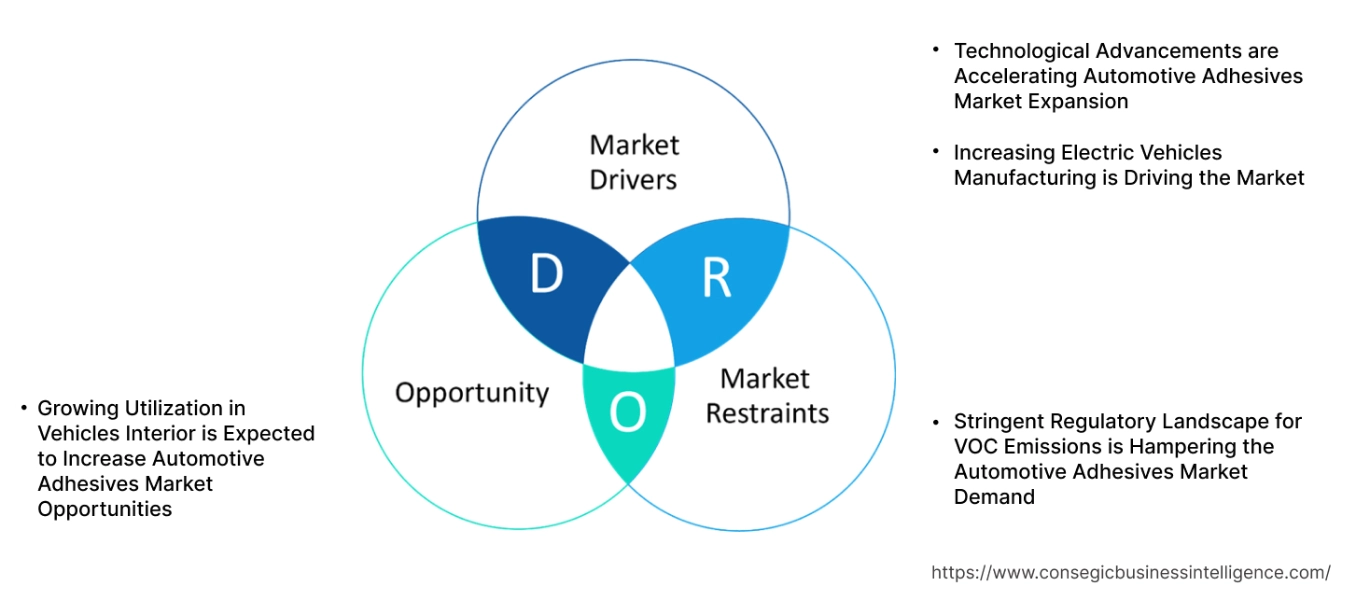

Automotive Adhesives Market Dynamics - (DRO) :

Key Drivers:

Technological Advancements are Accelerating Automotive Adhesives Market Expansion.

Automotive adhesives provide multiple advantages. New formulations are advantageous in bonding dissimilar materials. An example includes aluminum with advanced composites. Moreover, innovations in UV curing technologies are helpful in reducing assembly time. Additionally, viscoelastic adhesives are proven to be excellent in noise, vibration, and hardness. Furthermore, complex automotive electronics have required specialized adhesives used in potting. Consequently, manufacturers are launching new formulations, thus positively impacting automotive adhesives market trends.

For instance,

- In 2024, Henkel launched three potting adhesives for automotive applications. This includes Loctite SI 5035, Loctite AA 5832, and Loctite PE 8086 AB. These products are designed to protect components from harsh environmental conditions.

Overall, technological advancements are significantly boosting the automotive adhesives market expansion.

Increasing Electric Vehicles Manufacturing is Driving the Market.

Automotive adhesives are crucial for electric vehicles, as they are used to reduce the weight of vehicles. They serve as robust and strong bonding solution for multiple materials. This is helpful in reducing the risk of any component failure. Moreover, they are beneficial in transferring heat efficiently. This prevents vehicles from overheating and improves battery performance. Additionally, they provide extremely rigid vibration-dampened structure. This provides smooth handling and easy rides. The growing concerns over environment and government initiatives have led to increased manufacturing of these vehicles, thus requiring these adhesives for multiple applications.

For instance,

- According to International Energy Agency, the global sales of electric cars increased by 35% in 2023 when compared to previous year, thus positively impacting the automotive adhesives market trends.

Thus, increasing electric vehicles manufacturing is accelerating the global automotive adhesives market growth.

Key Restraints :

Stringent Regulatory Landscape for VOC Emissions is Hampering the Automotive Adhesives Market Demand.

Companies worldwide are facing increasing scrutiny related to volatile organic compounds (VOCs). This is because they are the most utilized components in automotive adhesives to improve performance. However, these VOCs have detrimental effects on human health and impact environmental negatively. Governments across different regions and countries are understanding these effects and are implementing regulations to reduce usage of VOCs. They are imposing certain limits of VOCs which are permissible for usage. They are also promoting solvent-free formulations. This has pushed manufacturers to invest in research and development activities to formulate new formulation with low VOCs or no VOCs. This is also increasing the product cost, as it is due to the usage of safer alternatives. Hence, the stringent regulatory landscape for VOCs is hampering the automotive adhesives market demand.

Future Opportunities :

Growing Utilization in Vehicles Interior is Expected to Increase Automotive Adhesives Market Opportunities.

Automotive adhesives are increasingly used in automotive interiors. They are beneficial in enhancing aesthetics. Moreover, they provide improving durability and placing these adhesives also secure that interiors are protected from external harsh conditions such as UV radiation, moisture, and extreme temperatures. They enable sleek designs by replacing traditional fasteners. They provide cleaner and premium look to dashboards, door panels, and consoles among others. Manufacturers are introducing new formulations which are designed specifically for interiors.

For instance,

- In 2024, Covestro launched Dispercoll U, which is a durable adhesive designed for automotive interiors. This creates potential for the market.

Overall, growing utilization in vehicles interiors is expected to increase the automotive adhesives market opportunities.

Automotive Adhesives Market Segmental Analysis :

By Type:

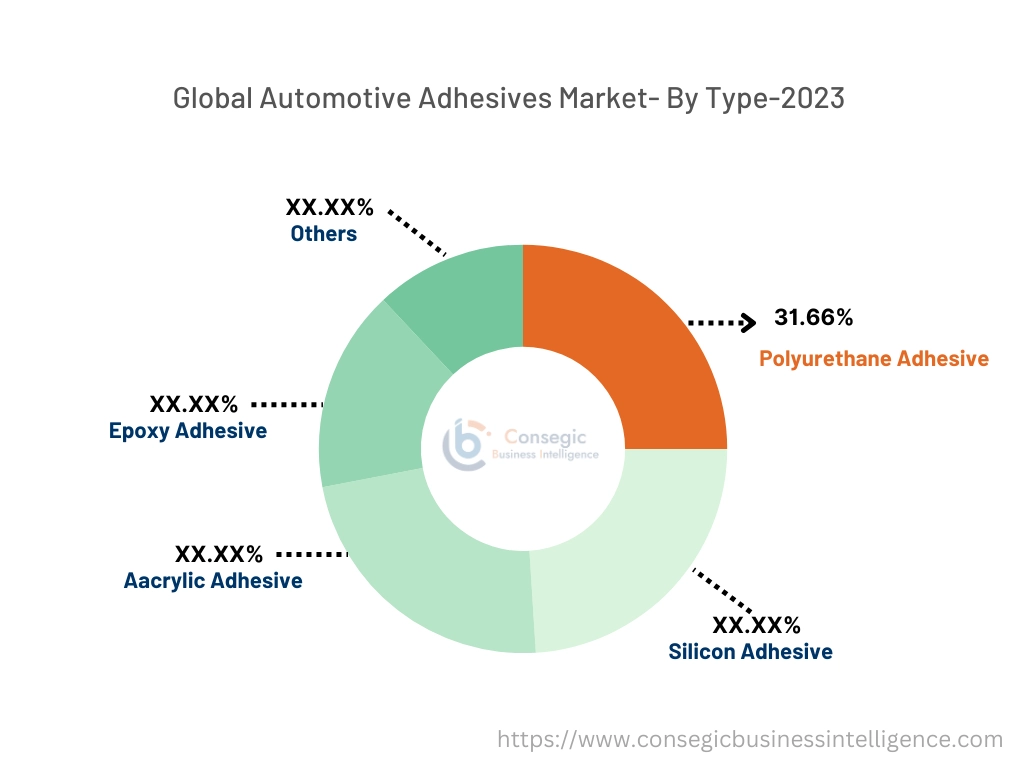

Based on type, the market is categorized into polyurethane adhesives, epoxy adhesives, acrylic adhesives, silicone adhesives, and others.

Trends in Type:

- There is a growing trend of using epoxy-based adhesives in structural bonding and battery assembly.

- Usage of acrylic-based adhesives in fast curing applications and bonding challenging materials such as composites is also a rising trend.

The polyurethane adhesives segment accounted for the largest market share of 31.66% in 2024.

- Polyurethane adhesives are known to be the most versatile class of adhesives. They provide excellent mechanical properties.

- They are manufactured by performing chemical reactions between polyols and isocyanates.

- They provide excellent rigid to flexible bonding properties on different types of substrates such as glass, plastics, and metals among others.

- They provide excellent protection against high moisture levels and protects from various fluids such as oil, solvents and fluids.

- Increasing demand for lighter and more efficient vehicles has pushed manufacturers to launch new products, thus driving segment.

- For instance, in 2023, Bostik and Polytec PT launched XPU TCA 202, which is a two-part polyurethane-based adhesive.

- Overall, as per the market analysis, the aforementioned factors are driving a segment in the automotive adhesives market growth.

The epoxy adhesives segment is expected to grow at the fastest CAGR over the forecast period.

- Epoxy adhesives are increasingly being utilized for structural bonding. They are manufactured by the chemical reaction performed between epoxy resin and a hardener.

- Epoxies are advantageous in providing exceptional strength. This makes it highly suitable for load bearing applications.

- They are also becoming crucial for engine components and body-in-white applications.

- Moreover, epoxies have low shrinkage during many processes such as curing. This leads to bonds which are precise and provide integrity maintenance without taking any stress. All these benefits are driving their increased usage.

- According to market analysis, the aforementioned factors will drive the segmental share for the upcoming years.

By Technology:

Based on technology, the market is categorized into water-based, solvent-based, hot melt, and others.

Trends in Technology

- There is a growing trend of innovating water-based adhesives to achieve superior bonds and excellent heat resistance.

- There is the development of water-based adhesives which have low VOC content. It incorporates biomaterials and aligns sustainable goals.

The water-based segment accounted for the largest market share in 2024 and is expected to grow at the fastest CAGR over the forecast period.

- Water-based technology denotes adhesives which contain water as a primary carrier medium for polymers.

- Water gets adsorbed into the substrate during the bonding process, which is beneficial in solidifying bonds.

- The primary advantage they provide is they have low volatile organic compounds, which is why manufacturers and government are promoting it.

- It reduces air pollution and is non-flammable. Moreover, it does not have an odor, which creates a safe environment for workers.

- Additionally, they prevent damage in the vehicle by providing excellent protection.

- Economic growth, rising disposable incomes, and urbanization have led to increasing demand for passenger cars, thus requiring these water-borne adhesives for multiple applications.

- For instance, according to GMK Center, the German passenger car production increased by 11% in year 2022, when compared to previous year.

- Overall, as per the market analysis, the aforementioned factors are driving segment in the automotive adhesives industry.

By Vehicle Type:

Based on vehicle type, the market is categorized into passenger vehicles and commercial vehicles.

Trends in Vehicle Type

- The growing shift towards electric vehicles is driving demand for adhesives in applications such as battery assembly and lightweighting.

- Commercial vehicle operators are investing in newer vehicles, which creates more demand for advanced adhesives for higher performance.

The commercial vehicles segment accounted for the largest market share in 2024.

- The commercial vehicles are further divided into heavy commercial vehicles and light commercial vehicles.

- In these vehicles, adhesives are used to increase fuel-efficiency. These adhesives also provide exceptional strength to vehicle structures such as body panels and make them lightweight.

- Moreover, they are also advantageous in reducing noise and vibrations in vehicles, which contributes to easy riding.

- The adhesives also provide excellent sealing properties, which protect vehicles from dust, moisture and high temperature. Growth of e-commerce and urbanization has led to an increase in these vehicles, thus requiring adhesives.

- For instance, according to TD Economics, the U.S. light vehicle market, saw a 12.7% increase in sales in year 2024, when compared to last year.

- Overall, as per the automotive adhesives market analysis, the aforementioned factors are driving the segment in the market.

The passenger vehicles segment is expected to grow at the fastest CAGR over the forecast period.

- In passenger vehicles, adhesives are important for bonding materials, which are difficult to join.

- They effectively bond materials, while also replacing traditional methods such as welding. This significantly contributes to the reduction of weight of passenger vehicles such as cars.

- Moreover, the segment is emerging as there is increased electrification in the sector. The booming production of electric vehicles is driving increased demand for these adhesives.

- They also provide excellent electrical insulation to the automotive parts and protect them from corrosion as well.

- Global safety regulations implemented by different regulatory bodies are further boosting the need for these adhesives.

- Thus, according to market analysis, the aforementioned factors are driving segmental growth for the forecasted years.

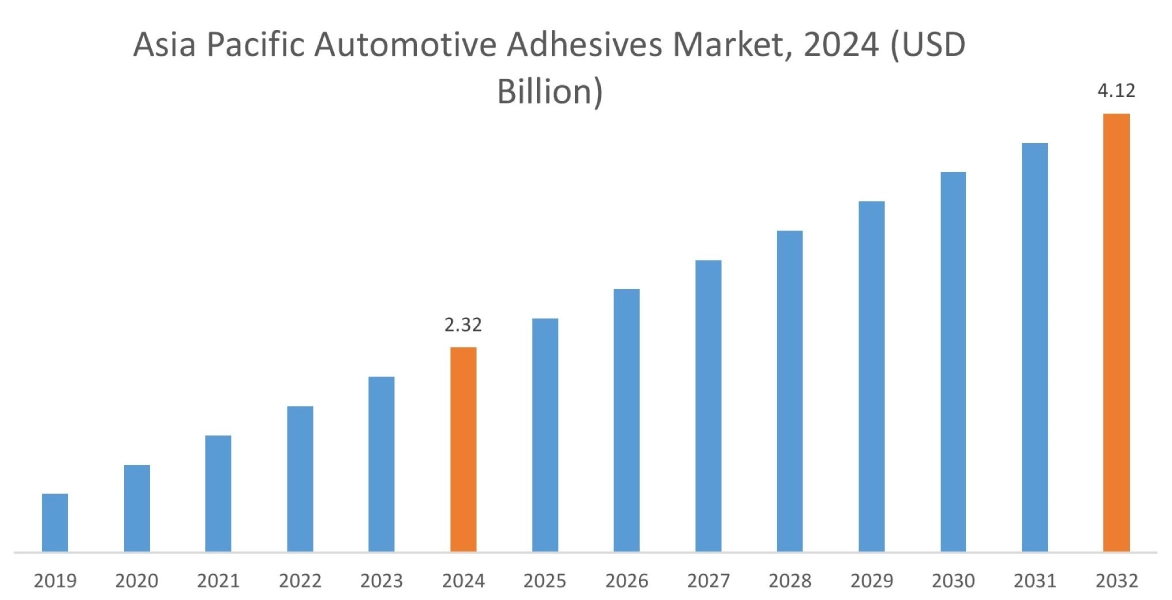

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest automotive adhesives market share at 36.75% and was valued at USD 2.32 Billion and is expected to reach USD 4.12 Billion in 2032. In Asia Pacific, the China accounted for the automotive adhesives market share of 23.11% during the base year of 2024. This region is the fastest growing automotive hub in the world. China, India, Japan, and South Korea are facing increased need for passenger cars. Adhesives in passenger cars are used to bond different parts such as interior trim pieces, dashboards, and upholstery among others. This provides a secure and durable fit. This has global manufacturers such as Henkel and SIKA to invest in the region in different forms thereby driving the market.

For instance,

- In 2023, Henkel, a German multinational company, initiated new adhesive manufacturing facility in China. The specific location is in the Yantai Chemical Industry Park within Shandong Province.

Overall, global adhesive manufacturers levering the growth of automotive sector is driving the market in the region.

In North America, the automotive adhesives market is experiencing the fastest growth with a CAGR of 7.7% over the forecast period. There is increasing the adoption of electric vehicles in the region. This is fueled by increasing government incentives and consumers increasingly favoring options which are sustainable and do not impact on the environment. This has pushed manufacturers to increase the production of electric vehicles, thus requiring adhesives. Adhesives are used to bond structural components such as roof panels, doors, and hoods. This reduces overall vehicle weight, while improving rigidity.

Europe's automotive adhesives market analysis indicates that several key trends are contributing to its growth in the region. There are lot of technological advancements going on in adhesives manufactured for automotive applications. European players are adopting advanced materials which are also safer and do contribute to the environment positively. New formulations are being developed to bond complex materials such as composites. Specific adhesives are being developed for interiors and exteriors. Moreover, new formulations are also manufactured with low VOC content.

Middle East and Africa (MEA) market analysis indicates that there is an increased usage of automotive electronics in the region. This includes advanced driver-assistance systems, automatic emergency braking, and adaptive cruise control among others. This is fueled by consumers seeking advanced features in vehicles. Adhesives are used in automotive electronics for potting and encapsulation. They bond sensitive electronic components and are beneficial in protecting them from thermal stress.

Latin America's region creates potential for the market. The region is facing increasing commercial vehicle production. This is fueled by increasing industrialization and infrastructure development. Moreover, the e-commerce sector is also booming. Countries such as Brazil and Argentina leads the market. They require adhesives for structural bonding for different parts. This includes truck cabins and trailer bodies among others. They provide structures with enhanced durability and improved safety. Moreover, these adhesives provide essential sealing for cargo compartments.

Top Key Players & Market Share Insights:

The Automotive Adhesives market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Automotive Adhesives market. Key players in The Automotive Adhesives industry include-

- B Fuller Company (United States)

- SIKA AG (Switzerland)

- Covestro AG (Germany)

- Huntsman International LLC (United States)

- PPG Industries, Inc (United States)

- Bostik (France)

- Henkel AG & Co. KGaA (Germany)

- LG Chem (South Korea)

- DuPont (United States)

- Dow (United States)

Recent Industry Developments :

Product Launch:

- In 2022, Dow Chemical launched VORATRON MA 8200S high-bonding adhesives for electric vehicle battery packs.This new generation of adhesives is designed to improve safety, durability, and sustainability.

Partnership:

- In 2021, DuPont and Nissan announced a technical partnership focused on the development and implementation of advanced adhesive solutions. This collaboration is aiming to enhance the performance of Nissan's Formula E race cars.

Automotive Adhesives Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2018-2031 |

| Market Size in 2031 | USD 11.52 Billion |

| CAGR (2024-2031) | 7.1% |

| By Type |

|

| By Technology |

|

| By Vehicle Type |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Automotive Adhesives market? +

In 2024, the Automotive Adhesives market is USD 6.65 Billion.

Which is the fastest-growing region in the Automotive Adhesives market? +

North America is the fastest-growing region in the Automotive Adhesives market.

What specific segmentation details are covered in the Automotive Adhesives market? +

Type, Technology and Vehicle Type segmentation details are covered in the Automotive Adhesives market.

Who are the major players in the Automotive Adhesives market? +

H.B Fuller Company (United States), SIKA AG (Switzerland), Bostik (France), Henkel AG & Co. KGaA (Germany), and LG Chem (South Korea) are some major players in the market.