Solid Masterbatches Market Size:

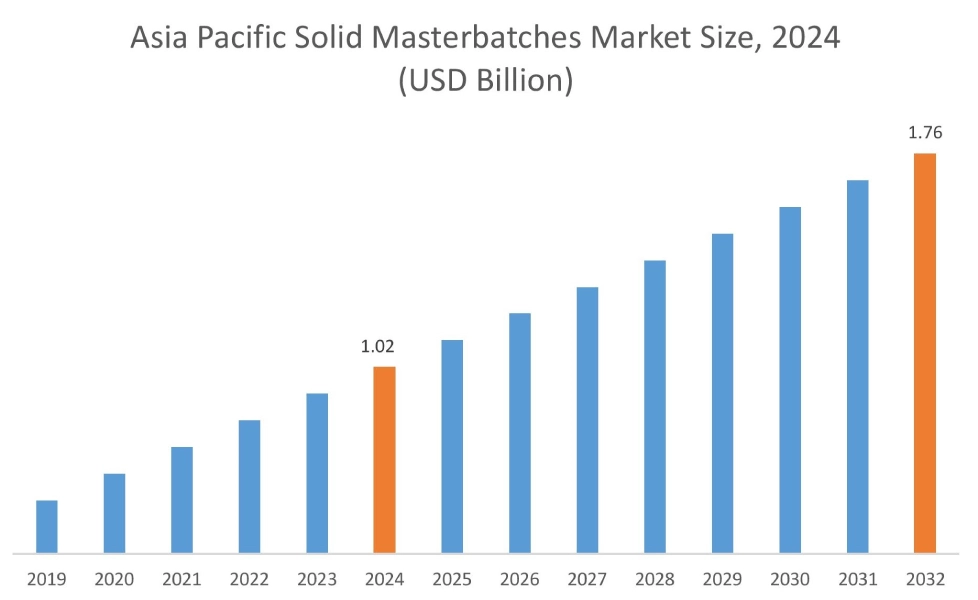

Solid Masterbatches Market size is growing with a CAGR of 5.9% during the forecast period (2025-2032), and the market is projected to be valued at USD 3.80 Billion by 2032 from USD 2.41 Billion in 2024. Additionally, the market value for the 2025 attributes to USD 2.54 Billion.

Solid Masterbatches Market Scope & Overview:

Solid masterbatches are solid and concentrated blends. It is made by mixing pigments, additives, fillers and a carrier resin. All these materials are then extruded, cooled, and pelletized into the mixture. The carrier resin is a wax or a polymer compatible with the base plastic. The key types include color masterbatches, which are used for aesthetics; additive masterbatches, which are used for functionalities such as flame resistance; and filler masterbatches, which are used for mechanical improvements. These masterbatches are used across diverse industries. Packaging is the main end-use for these mixtures. Other significant usage includes automotive, electrical & electronics, consumer goods, and construction among others.

Solid Masterbatches Market Dynamics - (DRO) :

Key Drivers:

Booming Packaging Sector is Accelerating Solid Masterbatches Market Expansion.

Solid masterbatches are used in the packaging sector to add color to the plastic packaging materials. It also provides UV protection and safeguard packaged contents from light degradation. Moreover, it improves anti-static properties. In flexible packaging, it is used in bags, films, and pouches. Additionally, in rigid packaging it is used in rigid containers, such as bottles, tubs, cups, and closures. There is a rise in demand for packaged goods. Consequently, manufacturers are increasing their production, thus raising the need for these masterbatches.

For instance,

- In 2024, Axium Packaging, which produces rigid plastic packaging for various products, opened its first Washington state manufacturing plant, thus positively impacting solid masterbatches market trends.

Overall, the booming packaging sector is significantly boosting the solid masterbatches market expansion.

Rising Automotive Manufacturing is Driving the Market.

Solid masterbatches provide precise color matching in the automotive parts. It improves scratch resistance and provides anti-fogging properties. Moreover, they provide impact modification. Additionally, heat management masterbatches are beneficial in improving battery life. These masterbatches are used in both interior and exterior parts. This includes seat covers, bumpers, mirrors, dashboards, and roof lining among others. Increasing demand for both commercial and passenger vehicles has led to sector growth, thus requiring these masterbatches in the production process.

For instance,

- According to the Germany Association of Automotive Industry, the passenger car production in Germany rose by 18% year-over-year, thus positively impacting solid masterbatches market trends.

Thus, the rising automotive manufacturing is accelerating the global solid masterbatches market growth.

Key Restraints:

Growing Commercialization of Alternatives is Hampering the Solid Masterbatches Market Demand.

The market faces competition from other substitutes available in the market such as liquid masterbatches and pre-compounded materials. Liquid masterbatches are beneficial in providing superior dispersion at low dosages. This is leading to more intense color and smooth surface finishes. Its pumpable nature provides manufacturers with easy and automated dosing. Also, it reduces dust and handling concerns. Moreover, powder pigments such as Titanium Dioxide, carbon black, and iron oxides; and powder additives such as UV stabilizers, flame retardants, and fillers serve as the most cost-effective per unit of active ingredient. Hence, the growing commercialization of substitutes is hampering the solid masterbatches market demand.

Future Opportunities :

Expanding Medical Device Sector is Expected to Increase Solid Masterbatches Market Opportunities.

In medical devices, these masterbatches in solid form are used to provide consistent coloration. They also provide specific properties to medical devices such as antimicrobial activity, chemical resistance, and UV resistance. These properties make medical devices durable and more reliable. Moreover, they also provide biocompatibility. This ensures safety for contact with the human body. Raising chronic disease prevalence and increasing healthcare spending has led to sector growth.

For instance,

- According to IBEF, the medical device market of India is expected to grow at a CAGR of 16.4% from 2022 to 2030. This creates the potential for the market.

Overall, expanding the medical device sector is expected to increase the solid masterbatches market opportunities.

Solid Masterbatches Market Segmental Analysis :

By Type:

Based on type, the market is categorized into color masterbatches, additive masterbatches, filler masterbatches, and others.

Trends in Type:

- There is a growing trend in using masterbatches which have attractive visual effects. This includes colors such as metallic, pearlescent, and fluorescent among others.

- Using filler masterbatches to impart properties such as stiffness and impact resistance is also a growing trend.

The color masterbatches segment accounted for the largest market share in 2024.

- Color masterbatches are blends with multiple pigments and dyes. Their primary usage is to impart colors to plastic products in manufacturing process.

- Apart from this, it also improves thermal conductivity and lightfastness of the products.

- It is used in multiple industries such as packaging (bottles, containers, films, and others), automotive (dashboards, doors, trims, bumpers, and others) and electricals & electronics (casings, wires, cables, connectors, and others).

- The rapid growth in these industries due to technological advancements and evolving consumer preferences is driving the segment share.

- For instance, according to Construction Connect, non-residential building construction in Canada saw a substantial increase of 22.5%.

- Overall, as per the market analysis, color masterbatches provide plastic aesthetics and strong performance across key industries is driving a segment in the solid masterbatches market growth.

The additive masterbatches segment is expected to grow at the fastest CAGR over the forecast period.

- Additive masterbatches are concentrated blends which enhance the mechanical properties of products.

- They provide improved durability and processibility. They also ensure uniform distribution of these critical additives. This leads to consistent product performance.

- Moreover, it enhances the overall performance of plastics. Additionally, it helps products meet regulatory requirements.

- They impart properties such as UV stabilization and extended shelf life. Additionally, it prevents fading and cracking, while providing flame retardancy for safety.

- Due to its benefits, it is used in multiple industries such as packaging, consumer goods, medical devices, and construction among others.

- According to market analysis, the aforementioned factors will drive the segmental share for the upcoming years.

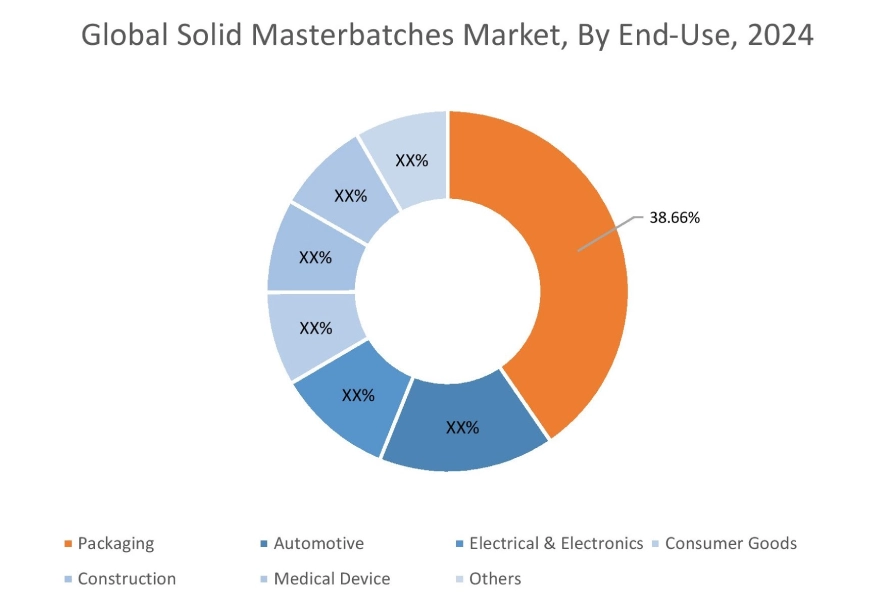

By End-Use:

Based on end-use, the market is categorized into packaging, automotive, electrical & electronics, consumer goods, construction, medical device, and others.

Trends in the End-Use

- Electronics miniaturization trend requires these solid masterbatches in appliances. This is to improve anti-static properties and flame retardancy.

- The increasing infrastructure development needs these masterbatches to make building materials durable and weather resistant.

The packaging segment accounted for the largest market share of 38.66% in 2024.

- Solid masterbatches in the packaging sector improve the appearance and functionality of the plastic products.

- It also improves physical properties and cost-efficiency of these products. Moreover, it enhances durability and provides barrier resistance.

- It is used in products such as shrink wraps, containers, tubs, bottles, films, bags, and pouches among others.

- Growing production of above-mentioned products is driving the need for these masterbatches. Subsequently, manufacturers are increasing their production capacity.

- For instance, in 2024, Global Packaging Solutions, a manufacturer of flexible packaging and pouches, expanded its operations in Albemarle, North Carolina.

- Overall, as per the market analysis, the growing plastic packaging production, including both flexible and rigid, is driving the segment in the solid masterbatches industry.

The medical device segment is expected to grow at the fastest CAGR over the forecast period.

- Masterbatches in solid form are used to provide coloration and biocompatibility in medical devices.

- They are a cost-effective way to add additives to the equipment’s compared to direct addition.

- Masterbatches are also easier to handle when compared to powdered additives. This reduces the risk of contamination and spills.

- Additionally, these masterbatches have a longer shelf life when compared to liquid additives.

- It also enhances the performance of medical devices by providing properties such as antimicrobial protection and flame resistance. These benefits provided by them in the medical device sector are fueling its increased usage.

- Thus, according to solid masterbatches market analysis, the aforementioned factors are driving segmental growth for the forecasted years.

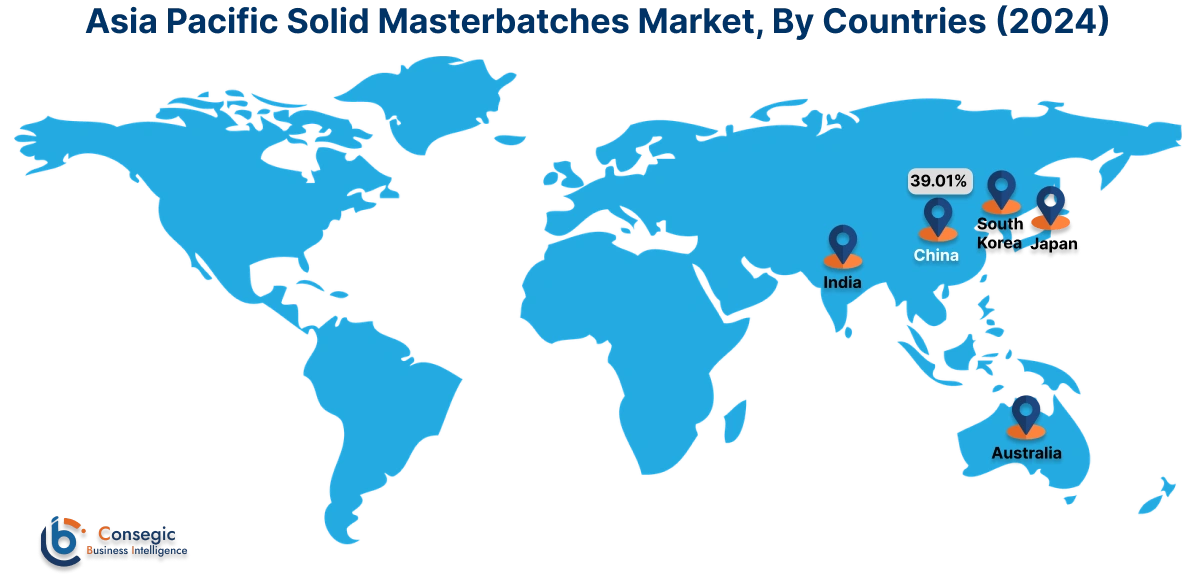

Regional Analysis:

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest solid masterbatches market share at 42.34% and was valued at USD 1.02 Billion and is expected to reach USD 1.76 Billion in 2032. In Asia Pacific, the China accounted for the solid masterbatches market share of 39.01% during the base year of 2024. The region is the major hub for vehicle production. This is fueled by increasing consumer demand for new vehicles and rising preferences for SUVs and trucks.

For instance,

- According to Asian Automotive Analysis, motor vehicle production of South Korea increased by 8.5% in 2022 when compared to previous year.

Masterbatches in solid form are used to provide durable coloration and aesthetics to parts such as trims, bumpers, door panels, and grill among others. Overall, the growing automotive sector is driving the market in the region.

In Europe, the solid masterbatches market is experiencing the fastest growth with a CAGR of 4.4% over the forecast period. The evolving consumer preference, technological advancements, and strict sustainability goals are driving eco-friendly packaging solutions in the region. Solid masterbatches impact vibrant colors in these packaging solutions. It also improves shelf life and barrier properties of plastic packaging products such as tubs, containers, films, and bottles among others. It also provides anti-static features for easy handling of the products.

North America’s solid masterbatches market analysis indicates that several key trends are contributing to its growth in the region. There is a rapid increase in the construction sector in the region. This is fueled by urbanization, substantial government investment, and infrastructure projects. Countries such as India, China, Japan, and South Korea leads the market. Masterbatches in solid form are used to enhance aesthetics of building materials. It also improves the durability of roofing and flooring. It helps in building materials with UV stability, flame retardancy, and anti-corrosion properties.

Middle East and Africa (MEA) market analysis indicates that the medical sector is rapidly growing in the region. This is driven by the rising chronic diseases, growing aging population, and increasing healthcare expenditure. Masterbatches in solid form provide biocompatibility to devices. This ensures its safety with human contact. Moreover, they also impart microbial protection features. This helps in reducing the risk of infection and increases hygiene. Additionally, they provide radiopacity for visibility during imaging procedures.

Latin America's region creates potential for the market. There is a rapid rise in consumer goods demand in the region. This is fueled by the increased rising disposable incomes and urbanization. Masterbatches in solid form are used in multiple consumer goods such as toys, home appliances, and houseware among others. It makes them durable and visually appealing. In some products, it provides glow-in-the-dark features. It also makes them impact resistance and

Top Key Players and Market Share Insights:

The Solid Masterbatches market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Solid Masterbatches market. Key players in The Solid Masterbatches industry include-

- Americhem (United States)

- Holland Colours (Netherlands)

- Lifeline Technologies (India)

- AF-COLOR (Germany)

- ColoPlas LLP (Denmark)

- Universal Masterbatch LLP (India)

- Avient (United States)

- Tosaf (Israel)

- Sun Chemical (United States)

- Perfect Colourants and Plastics Pvt. Ltd. (India)

- Color Master Inc. (United States)

- REPIN Masterbatches (India)

Recent Industry Developments :

Product Launch:

- Americhem Healthcare recently launched ColorRx, a product line of pre-colored masterbatches. It is designed to meet the specific needs of medical device manufacturers in the European market.

Solid Masterbatches Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 3.80 Billion |

| CAGR (2025-2032) | 5.9% |

| By Type |

|

| By End-Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Solid Masterbatches market? +

In 2024, the Solid Masterbatches market is USD 2.41 Billion.

Which is the fastest-growing region in the Solid Masterbatches market? +

Europe is the fastest-growing region in the Solid Masterbatches market.

What specific segmentation details are covered in the Solid Masterbatches market? +

Type and End-Use segmentation details are covered in the Solid Masterbatches market

Who are the major players in the Solid Masterbatches market? +

Americhem (United States), Avient (United States), Tosaf (Israel), Sun Chemical (United States), Perfect Colourants and Plastics Pvt. Ltd. (India), and Color Master Inc. (United States) are some major players in the market.