Packed Bed Reactor Market Size:

The Packed Bed Reactor Market size is growing with a CAGR of 6.1% during the forecast period (2025-2032), and the market is projected to be valued at USD 4.17 Billion by 2032 from USD 2.60 Billion in 2024. Additionally, the market value for 2025 is attributed to USD 2.75 Billion.

Packed Bed Reactor Market Scope & Overview:

A Packed Bed Reactor (PBR) is designed as a cylindrical vessel filled with a stationary bed of solid particles for chemical processing. This allows fluid reactants to flow through the packed bed continuously. It enables chemical reactions on the catalyst's surface. These reactors are considered as a suitable choice for their ability to provide large surface areas for fluid-solid interaction. These reactors are crucial across the chemical industry for processes such as methanol synthesis, petroleum refining, along with the increase in environmental applications and pharmaceutical manufacturing due to their scalability and improved efficiency.

Packed Bed Reactor Market Dynamics - (DRO) :

Key Drivers:

Growing Demand for Specialty and Fine Chemicals is Driving the Packed Bed Reactor Market Growth.

The specialty and fine chemicals are driving the need for packed bed reactors due to the production of complex chemicals that often require heterogeneous catalytic reactions, for which these reactors are suitable options. Their design allows for strong control for achieving the high purity required by these products. Furthermore, the increasing focus towards continuous manufacturing in the pharmaceutical sector for Active Pharmaceutical Ingredient (API) synthesis is contributing to the adoption rate of these reactors.

- For instance, according to IBEF, the specialty chemicals contribute around 1/5 of the chemical market across the globe with a steady growth rate of 4%.

Hence, due to the aforementioned factors, growing demand for specialty and fine chemicals is driving the development of the market.

Expansion in Petrochemical and Refining Sectors is Accelerating the Market Development

The expanding petrochemical and refining sectors require packed bed reactors for several necessary processes. Petrochemical and refining operations are reliant on heterogeneous catalytic reactions to convert crude oil as well as natural gas into chemical feedstocks and fuels. PBRs are used to remove impurities, to produce high-octane gasoline components, amongst others. The global surge in energy demand, along with the increasing focus towards new refinery and petrochemical plant construction is contributing to the demand of these reactors.

- For instance, according to IEA, China contributes to roughly 60% of the petrochemical need across the globe with a steady growth rate of 5% observed in 2024.

Thus, owing to the afore-mentioned factors, the growing petrochemical and refining sectors is accelerating the packed bed reactor market expansion.

Key Restraints:

Inflexibility in Handling Fouling or Solid Byproducts to Hinder Packed Bed Reactor Market Growth

During operations, collection of coke, fine particles, or other solid depositions within the packed bed are created that causes a considerate increase in pressure drop. This leads to an increase in energy consumption leading to production shutdowns. This fouling reduces catalyst activity, leading to lower conversion rates, increase in the cost of material, amongst others. Consequently, this restrains the adoption rate of reactors due to their utilization in a less suitable sensitive application, directly hindering their broader market revenue. This leads to sectors finding alternative reactor technologies in such applications. Therefore, the above-mentioned factors are contributing to hinderance in packed bed reactor market expansion.

Future Opportunities :

Expansion in Pharmaceutical Continuous Manufacturing to Create Packed Bed Reactor Market Opportunities

Drug manufacturers are changing preferences form traditional processes to enhance product quality, obtain efficiencies, improve safety amongst others. PBRs are a suitable option for their inclusion as they are designed for continuous flow required in the synthesis of oncology active pharmaceutical ingredients. This aligns with the aim of pharmaceutical companies for streamlined and controlled production, in turn creating potential pathways for these reactors as a key technology poised this sector.

- For instance, according to the International Society for Pharmaceutical Engineering (ISPE), the pharmaceutical manufacturing industry in the U.S. is expected to growth at a CAGR of more than 6% with expected 30% of the new drugs produced with the help of AI.

Thus, due to the aforementioned factors, expanding in pharmaceutical continuous manufacturing are expected to create packed bed reactor market opportunities.

Packed Bed Reactor Market Segmental Analysis :

By Reactor Type:

Based on Reactor Type, the market is categorized into fixed bed reactors, moving bed reactors, trickle bed reactors, and others.

Trends in Reactor Type:

- The growing focus on manufacturers on optimizing fixed bed designs for improved heat management, reduced pressure drops amongst others.

- The adoption of trickle bed reactors in biological wastewater treatment is increasing.

The fixed bed reactors segment accounted for the largest packed bed reactor market share in 2024.

- Fixed bed reactors is the most prevalent type due to their robust design along with efficacy across a wide range of end use sectors.

- Their dominance is attributed to their utilization in large-scale production of bulk chemicals such as methanol, ammonia, sulfuric acid amongst others.

- Additionally, fixed bed reactors are also preferred in the petrochemical and refinery for operations such as catalytic reforming and hydrotreating.

- Furthermore, advancements in the development of more efficient catalysts contribute to their high necessity for new fixed bed units.

- Thus, as per the packed bed reactor market analysis, the fixed bed reactor segment is dominating the packed bed reactor market demand.

The trickle bed reactors segment is expected to grow at the fastest CAGR over the forecast period.

- Trickle Bed Reactors (TBRs) are increasingly preferred due to their specific design for managing complex reactions that involve gas, liquid, and solid catalyst.

- One of the major factors contributing to segmental growth is their importance in hydro processing in the oil and gas refining sector.

- For instance, according to S. Energy Information Administration, the refining capacity between the Middle East and Asia Pacific will grow up to more than 2.5 million barrels a day by 2028.

- Additionally, TBRs are expected to be a suitable option in the production of advanced biofuel further contributing to the requirement.

- Thus, based on the packed bed reactor market analysis, the trickle bed reactors segment is the fastest growing segment in the market.

By Application:

The Application segment is categorized into petrochemicals, polymer production, chemical synthesis, and others.

Trends in the Application

- The prominent preference for PBRs is in the hydrotreating process for production of key intermediates in the petrochemical sector is a key trend.

- The growing utilization in specific gas-phase polymerization processes for chemical synthesis is a trend positively impacting the market.

The petrochemicals segment accounted for the largest market share in 2024 and is expected to grow at the fastest CAGR over the forecast period.

- The petrochemical sector maintains a dominant position due to the increasing requirements for both transport fuels and the chemicals that are derived from crude oil and natural gas across the globe.

- Reactor beds are important for operations such as removing impurities and hydrotreating, amongst others.

- Furthermore, ongoing investments in new refinery and petrochemical plant capacities, particularly across Asia-Pacific and the Middle East are contributing to the high need of these reactors.

- For instance, according to S&P Global, two new projects in Saudi Arabia to increase the capacity of petrochemicals up to more than 5 million tons per year.

- Thus, based on the market analysis, as per the aforementioned factors, the petrochemicals segment is dominating as well as the fastest growing packed bed reactor market demand.

By End Use:

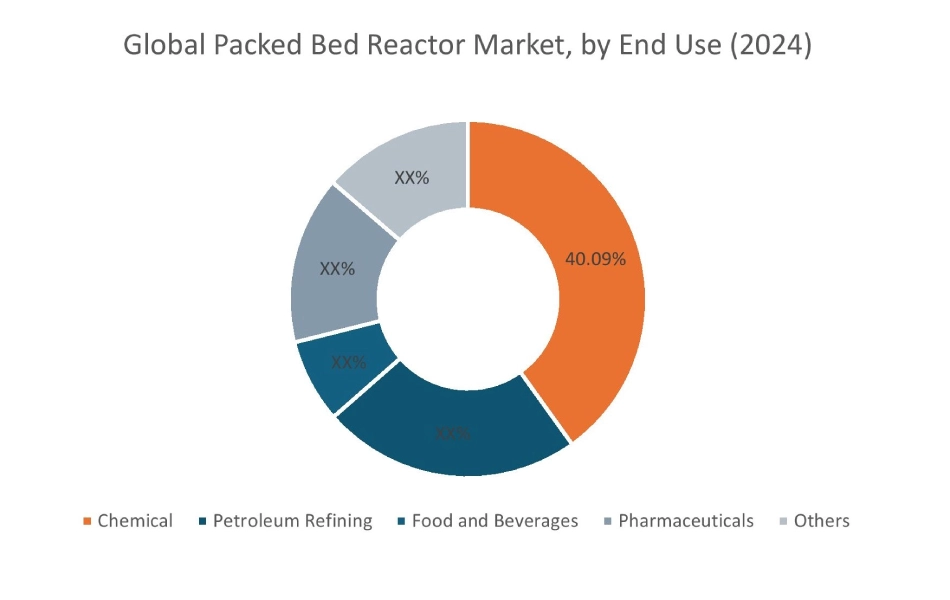

The End Use segment is categorized into chemical, petroleum refining, food and beverages, pharmaceuticals, and others.

Trends in the End Use

- The chemical sector is expected to contribute to its prominence due to large-scale production of bulk chemicals.

- The pharmaceuticals sector focuses on continuous manufacturing with aim towards improved efficiency and product quality.

The chemicals segment accounted for the largest packed bed reactor market share of 40.09% in 2024.

- The chemical sector is the prominent end-user due to the usage of PBR’s into the production process of several chemicals, such as ammonia, methanol, sulfuric acid amongst others as these reactors are used for complex synthesis of specialty and fine chemicals.

- The focus of chemical manufacturers towards enhanced efficiency, production process optimization and others are contributing to the need for reactor designs and their development.

- Moreover, the sector’s inclination towards green chemistry and sustainable manufacturing processes is providing new applications for the utilization of reactors.

- Thus, based on the market analysis, as per the aforementioned factors, the chemicals segments are dominating the market.

The others segment is expected to grow at the fastest CAGR over the forecast period.

- The others segment includes environmental engineering, biofuel and others.

- The utilization of packed bed reactors in air pollution control such as VOC removal along with its usage in advanced wastewater treatment processes are contributing to the waste removal potential of these reactors.

- Simultaneously, the growing biofuel sector consistently with requirement for these reactors in their aim towards sustainable processes such as biomass conversion and the production of biodiesel.

- For instance, according to IEA, biofuel demand across the globe is expected to increase to 38 billion liters by 2028, showcasing an increase of more than 25% from 2023.

- Thus, based on the market analysis and aforementioned factors, the others segment is the fastest growing segment in the industry trends.

Regional Analysis:

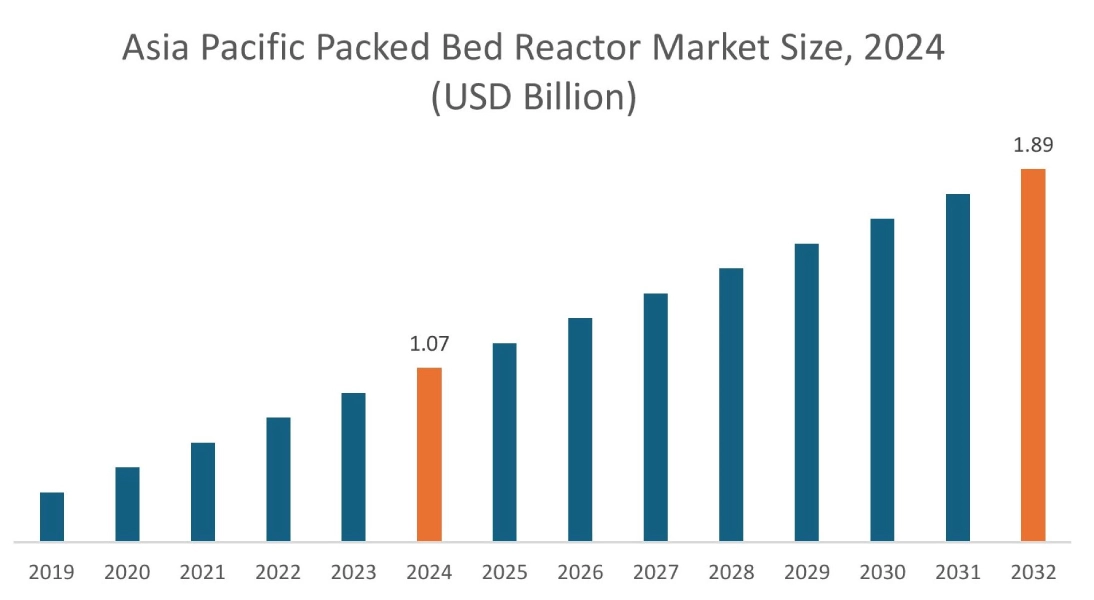

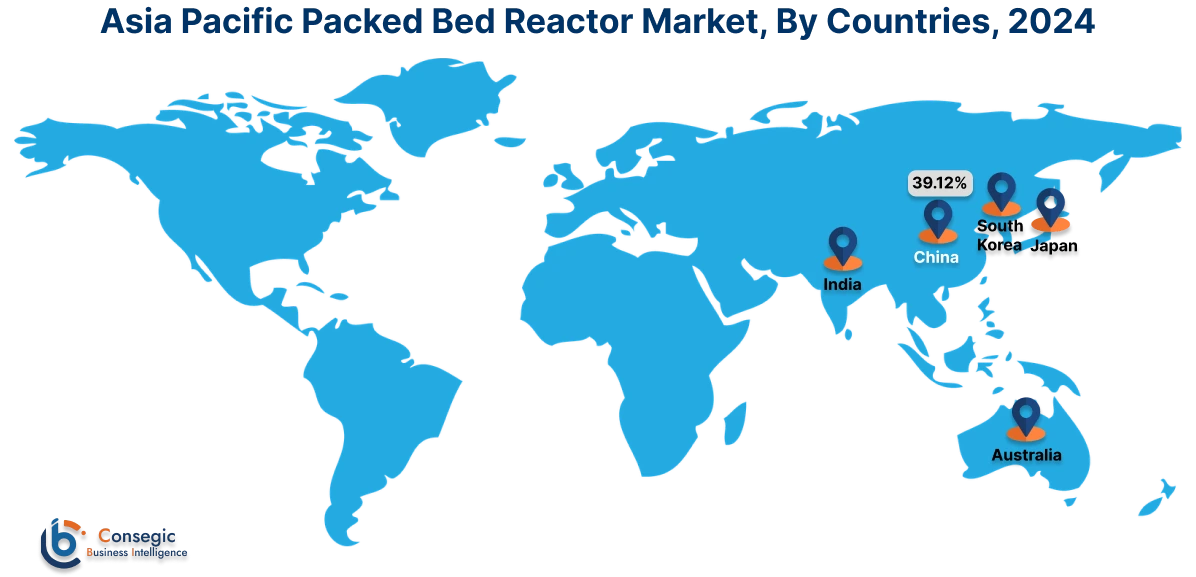

The regional segment includes North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America.

In 2024, Asia Pacific accounted for the highest market share at 41.31% and was valued at USD 1.07 million and is expected to reach USD 1.89 million in 2032. In Asia Pacific, China accounted for the market share of 39.12% during the base year of 2024. The increasing need for specialty and fine chemicals is the primary driver for the market growth in the Asia Pacific region. Asia Pacific countries such as China, India are experiencing industrialization and urbanization, thereby requiring a continuous need for value chemicals across diverse sectors. As these countries are global manufacturing hubs, packed bed reactors are required for efficient production. Additionally, the focus on investments in advanced catalytic processes along with the rising necessity for specialty and fine chemicals are further contributing to the market revenue in Asia Pacific.

- For instance, according to Independent Commodity Intelligence Services, China added an increase capacity of 18.7m tons/year of chemical production in 2024.

Based on the market analysis, these factors create a strong upward trajectory for the market in Asia Pacific, positioning it as a key region for players.

In Europe, the packed bed reactor industry is experiencing the fastest growth with a CAGR of 7.2% over the forecast period. In Europe, the petrochemical and refining sectors contribute significantly to the market due to the focus on upgradation of existing facilities to reduce emissions, enhance efficiency, and others. Additionally, stringent environmental regulations on fuel quality require continuous investment in reactors, particularly trickle bed reactors (TBRs) for removal of impurities. Furthermore, the integration of refining and petrochemical to develop high value chemicals require specialized reactor units. These above-mentioned factors are contributing to the packed bed reactor market trends in this region

The increase in the adoption rate of continuous manufacturing, particularly for APIs production in the North American pharmaceutical region is contributing to a majority of requirement of these reactors. APIs and intermediates are synthesized through heterogeneous catalytic reactions wherein these reactors are a suitable option. These reactors provide simplified downstream processing, efficient catalyst utilization, and others. This has led to an increase in the need for PBRs generating higher revenue in the North American region.

The current investments in infrastructure development of significant nature in Latin America are contributing to the revenue of market in the region. This is driven by the need for basic chemical and construction materials for the region's projects. Additionally, crucial improvements in water and wastewater treatment facilities are using packed bed reactors for treatment and purification. Moreover, the growing energy sector is growing, including new power plants that need these reactors for processes such as hydrogen production. These factors collectively contribute to the Latin American packed bed reactor market trend.

The expanding biofuel and biorefinery sectors in the Middle East and Africa (MEA) regions offer potential for the market revenue. These opportunities are supported by factors such as governmental pushes for economic diversification apart from fossil fuels, increasing environmental sustainability goals, and others. This also includes utilizing the vast amount of local biomass feedstocks available for biofuel production. These reactors are important in the transesterification reactions for biodiesel production to the enzymatic hydrolysis of biomass for bioethanol.

Top Key Players and Market Share Insights:

The Global Packed Bed Reactor Market is highly competitive with major players providing products to the national and international markets. Key players are adopting several strategies in research and development (R&D) and product innovation to hold a strong position in the global Packed Bed Reactor market. Key players in the Packed Bed Reactor industry include

- Vapourtec (UK)

- Amar Equipments (India)

- Lelesil Innovative Systems (India)

- Trident Labortek (India)

- Parker Autoclave Engineers (United States)

- AP-Miniplant GmbH (Germany)

- WINKELS GmbH (Germany)

Packed Bed Reactor Market Report Insights :

| Report Attributes | Report Details |

| Study Timeline | 2019-2032 |

| Market Size in 2032 | USD 4.17 Billion |

| CAGR (2025-2032) | 6.1% |

| By Reactor Type |

|

| By Application |

|

| By End Use |

|

| By Region |

|

| Key Players |

|

| North America | U.S. Canada Mexico |

| Europe | U.K. Germany France Spain Italy Russia Benelux Rest of Europe |

| APAC | China South Korea Japan India Australia ASEAN Rest of Asia-Pacific |

| Middle East and Africa | GCC Turkey South Africa Rest of MEA |

| LATAM | Brazil Argentina Chile Rest of LATAM |

| Report Coverage |

|

Key Questions Answered in the Report

How big is the Packed Bed Reactor market? +

In 2024, the Packed Bed Reactor market is USD 2.60 Billion.

Which is the fastest-growing region in the Packed Bed Reactor market? +

Europe is the fastest-growing region in the Packed Bed Reactor market.

What specific segmentation details are covered in the Packed Bed Reactor market? +

By Reactor Type, Application and End Use segmentation details are covered in the Packed Bed Reactor market.

Who are the major players in the Packed Bed Reactor market? +

Parker Autoclave Engineers (United States), Vapourtec (UK), AP-Miniplant GmbH (Germany), Th. WINKELS GmbH (Germany) are some of the major players in the market.